Vacuum Casting Shore Hardness Chart: A Practical Guide

When designing a new product, engineers often focus on its strength and dimensions. However, for many applications, the "feel" of a part is just as critical. The softness of a button, the flexibility of a seal, or the rigidity of a housing are all essential functional characteristics. In the world of vacuum casting, these properties are defined and controlled by one key specification: Shore hardness. Understanding this measurement is essential for selecting the right material to create a perfect, production-quality prototype.

Shore hardness is a standardized measure of a material's hardness or its resistance to permanent indentation. For vacuum casting, it is the primary specification used to select a polyurethane resin that accurately mimics the feel of a soft, flexible rubber, a semi-rigid plastic, or a hard, rigid engineering polymer. Choosing the correct durometer is key to creating a prototype that not only looks right but also feels and functions correctly.

As an expert in material science for urethane casting, GD-Prototyping guides clients through the material selection process. This ensures the final parts meet their exact tactile and mechanical requirements. This guide provides a comprehensive overview of Shore hardness. We will explain the science behind it, provide a detailed chart of available materials, and offer practical advice on how to select the perfect hardness for your project. This is a key concept within the broader Urethane Casting Guide.

What is Shore Hardness? A Deep Dive into Durometer

To select the right hardness, it is first necessary to understand what the measurement represents and how it is obtained. The term "Shore hardness" comes from the instrument used to measure it, which is called a durometer. The durometer was developed by Albert Ferdinand Shore in the 1920s.

The Science of Measuring Material Hardness

A durometer is a mechanical device designed to measure the hardness of soft materials like elastomers and plastics. The process is non-destructive and relatively simple.

- The durometer has a spring-loaded indenter pin of a specific shape.

- The operator presses the durometer firmly against a flat sample of the material.

- The spring pushes the indenter into the material's surface.

- The hardness value is determined by how deep the indenter penetrates the material. A deep penetration indicates a soft material, resulting in a low durometer reading. A shallow penetration indicates a hard material, resulting in a high durometer reading.

The measurement is read from a dial or digital display on a scale from 0 to 100. It is a dimensionless number (it has no units).

Understanding the Shore Scales: A vs. D

It is impossible to measure the full spectrum of material hardness, from soft gels to hard plastics, with a single instrument. For this reason, there are several different Shore hardness scales. For casting polyurethanes, the two most important and common scales are Shore A and Shore D.

The Shore A Scale

The Shore A scale is used to measure soft to semi-rigid materials. This includes everything from very soft, flexible rubbers to semi-rigid plastics with limited flexibility. The durometer for the A scale uses an indenter with a blunted, truncated cone shape.

The Shore D Scale

The Shore D scale is used to measure much harder materials. This includes hard rubbers and rigid engineering-grade plastics. The durometer for the D scale uses an indenter with a sharper, pointed cone shape. This sharper point is necessary to penetrate the harder surface of these materials.

It is critical to understand that these two scales overlap, but they are not directly convertible. A material at the top end of the A scale (e.g., 95A) is much softer than a material at the low end of the D scale (e.g., 50D). They are distinct measurement systems. A specification for hardness is incomplete without the letter (A or D).

Why Hardness Matters for Prototypes

Specifying the correct hardness is essential for creating a functional prototype.

- Ergonomics: For any handheld product, the hardness of a grip or button directly impacts user comfort and perception of quality.

- Sealing: The hardness of a gasket or seal determines its ability to compress and conform to a surface to prevent leaks.

- Impact Resistance: Softer materials can absorb more impact energy without cracking, making them ideal for protective bumpers and overmolds.

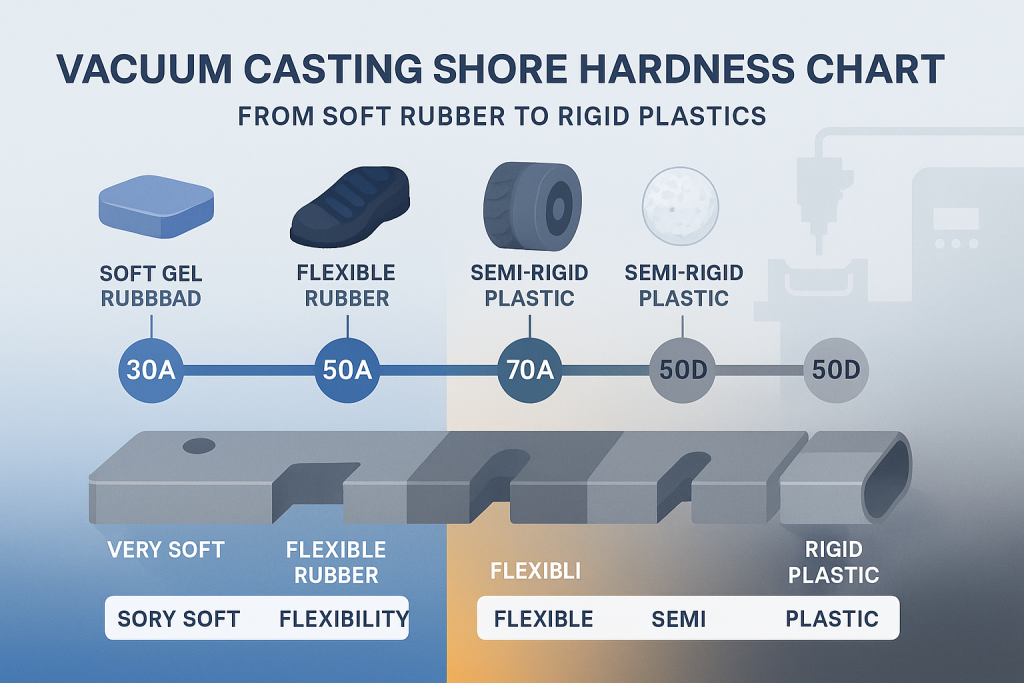

The Vacuum Casting Shore Hardness Chart

This chart serves as a practical guide for engineers and designers. It connects the numerical Shore hardness values to real-world analogies and common applications. This helps to translate an abstract number on a datasheet into a tangible, intuitive "feel" for the material.

| Shore Hardness | Feel & Flexibility | Common Real-World Analogy | Ideal Vacuum Casting Applications | Example Resin Simulant |

| 30A | Very Soft & Gel-Like. Stretches easily. | A soft rubber band. Gel shoe insole. | Medical skin-contact pads, soft-touch buttons, dampers, special effects props. | Very Soft Rubber |

| 40A | Soft & Rubbery. Very flexible. | A pencil eraser. | Wearable prototypes, soft, pliable grips, compliant seals. | Soft Rubber |

| 50A | Medium-Soft Rubber. Good flexibility. | A standard rubber stamp. | Squeegees, flexible joints, protective covers for electronics. | Medium-Soft Rubber |

| 60A | Firm but Flexible Rubber. | A car tire tread. | Gaskets, seals, flexible housings, shock and vibration absorbers. | Medium Rubber |

| 70A | Medium-Hard Rubber. Limited stretch. | A shoe heel. | Overmolded wheels, rollers, firm grips for tools and sporting goods. | Medium-Hard Rubber |

| 80A | Hard Rubber. Stiff with some flex. | A leather belt. | Protective bumpers, impact pads, firm wheels for industrial carts. | Hard Rubber |

| 90A | Very Hard Rubber / Semi-Rigid Plastic. | A shopping cart wheel. | Hard wheels, grommets, structural seals, parts requiring high abrasion resistance. | Very Hard Rubber |

| 50D | Semi-Rigid Plastic. Very little flex. | A golf ball. | Snap-fit enclosures, housings requiring some impact resistance, automotive trim. | Polypropylene (PP) |

| 65D | Rigid & Stiff Plastic. | A construction hard hat. | Housings, enclosures, prototypes requiring the stiffness of unfilled production plastics. | Polypropylene (PP) |

| 75D | Very Rigid Plastic. High impact strength. | A cast ABS plastic part. | Enclosures, mounting brackets, functional prototypes for mechanical testing. | ABS (Acrylonitrile Butadiene Styrene) |

| 85D | Extremely Rigid & Hard. High stiffness. | A PVC pipe. | Housings for electronics, high-stiffness structural components, master patterns. | ABS / PC (Polycarbonate) |

An In-Depth Look at the Shore A Scale (Soft & Flexible)

The Shore A scale covers the full range of flexible, rubber-like materials. Choosing the right durometer on this scale is key to achieving the desired level of softness, flexibility, and elasticity for your prototype.

30A – 50A: Very Soft and Gel-Like

Materials in this range are extremely soft and pliable. They feel similar to a soft rubber band and can be easily stretched and compressed.

- Feel and Flexibility: These materials have a gel-like consistency. They offer excellent shock absorption and damping properties. They have a high degree of elasticity, meaning they return to their original shape after being deformed.

- Applications: This range is ideal for applications that require a soft touch or a high degree of compliance. Common uses include prototypes for medical skin-contact pads, soft, squishy buttons on electronic devices, and custom vibration dampers for sensitive equipment.

60A – 70A: Medium Soft Rubber

This is the "sweet spot" for many common rubber applications. Materials in this range are firm but still highly flexible.

- Feel and Flexibility: These materials feel like a car tire tread or a high-quality pencil eraser. They are robust and durable while still offering excellent flexibility and sealing properties.

- Applications: This is the most common range for creating gaskets and seals. The material is hard enough to be durable but soft enough to compress and create a watertight seal. It is also excellent for flexible grips, protective covers for electronics, and shock-absorbing components.

80A – 90A: Hard Rubber / Semi-Rigid Plastic

Materials at the top end of the Shore A scale begin to transition from flexible rubber to semi-rigid plastic. They are very stiff and offer limited flexibility.

- Feel and Flexibility: A 90A material feels similar to the hard rubber of a shopping cart wheel or the sole of a leather shoe. It can be bent with significant force but is not truly elastic.

- Applications: This range is used for parts that require high durability and abrasion resistance but still need some compliance. Common uses include hard overmolded wheels for carts, firm protective bumpers on industrial equipment, and structural grommets.

An In-Depth Look at the Shore D Scale (Hard & Rigid)

The Shore D scale is used for materials that range from semi-rigid to extremely hard and stiff plastics. This scale is used when selecting a resin to simulate common production thermoplastics like PP, ABS, or PC.

50D – 65D: Medium Hard Plastic

This range represents the lower end of the rigid plastics scale. Materials here have very little flex and are considered semi-rigid.

- Feel and Flexibility: A 65D material feels similar to a construction hard hat. It is a tough and durable plastic. It will deform slightly under a heavy load but will not easily bend.

- Applications: This is an excellent choice for simulating general-purpose production plastics like Polypropylene (PP). It is commonly used for creating prototypes of housings and enclosures, especially those that will incorporate snap-fit features, which require a small amount of flex to function correctly.

70D – 85D: Very Hard and Rigid

This is the most common range for creating prototypes of rigid engineering components. Materials in this range are extremely hard, stiff, and strong.

- Feel and Flexibility: An 85D material feels like a PVC pipe or a cast ABS plastic part. It has virtually no flexibility and is designed for stiffness and structural integrity.

- Applications: This is the ideal range for creating high-fidelity prototypes of rigid parts. Common uses include enclosures for electronic devices, mounting brackets, structural components, and any part that needs to accurately simulate the strength and stiffness of production-grade ABS or Polycarbonate (PC). These materials are also strong and stable enough to be used as master patterns for subsequent urethane casting projects.

The Overlap Zone: 90A vs. 50D

It is a common point of confusion, but a material with a high Shore A value is not the same as a material with a low Shore D value. For example, a 90A polyurethane is a very hard rubber. A 50D polyurethane is a semi-rigid plastic. The 90A material is significantly softer and more flexible than the 50D material. The scales are not continuous.

How to Select the Right Hardness for Your Project

Choosing the right durometer can seem daunting. However, a practical, step-by-step approach can simplify the decision.

A Practical Decision-Making Guide

- Define the Primary Function: Start by defining what the part must do. Is it a seal that needs to compress? Is it a grip that needs to be comfortable? Is it a housing that must be rigid and protective? The function will immediately narrow down the possible hardness range.

- Find a Real-World Object: The best way to understand durometer is to use a physical reference. Find an existing product in the real world that has the exact "feel" you are trying to achieve. You can then use online resources to look up the typical Shore hardness of that object (e.g., "Shore hardness of a shoe heel"). This provides a tangible target.

- Consider the Mating Parts: Think about how your part will interact with other components in the assembly. A hard plastic part rubbing against another hard plastic part may require a different material choice than one interacting with a metal component.

- Consult Your Manufacturing Partner: The best practice is to discuss your application with an expert. A knowledgeable manufacturing partner like GD-Prototyping can listen to your functional requirements and recommend a specific polyurethane resin that will provide the perfect hardness and performance characteristics for your prototype.

Hardness, Tolerances, and Other Properties

Shore hardness is a critical property, but it does not exist in a vacuum. It is often related to other material properties and can influence other aspects of the final part.

Hardness and Tolerances

Very soft materials (below 50A) can be more challenging to measure precisely. Their flexible nature means that they can deform slightly during the inspection process. For this reason, parts cast from very soft elastomers may have slightly looser achievable dimensional tolerances than parts cast from rigid materials. For detailed specifications on the accuracy of the process, it is important to see our Vacuum Casting Tolerances guide.

Hardness vs. Other Properties

While not a perfect correlation, Shore hardness is often related to other mechanical properties. Generally, as a material's hardness increases, its tensile strength and abrasion resistance also increase. However, its flexibility and elongation at break will decrease. It is important to review the full technical datasheet for a specific polyurethane resin to understand all of its properties, not just its durometer.

Conclusion

Shore hardness is a critical specification in the world of vacuum casting. It is the language that engineers use to define the tactile and functional properties of a prototype part. By moving beyond abstract terms like "soft" or "hard" to a standardized numerical scale, it allows for the precise selection of a material that will feel and perform exactly as intended. From a soft, gel-like damper to a rigid, ABS-like housing, the vast range of available polyurethane resins makes it possible to simulate nearly any production plastic.

Understanding the Shore A and D scales and relating them to real-world applications is the key to success. Partnering with a manufacturing expert who can provide guidance and a wide selection of materials is the surest path to creating a perfect, production-quality prototype.