Vacuum Casting

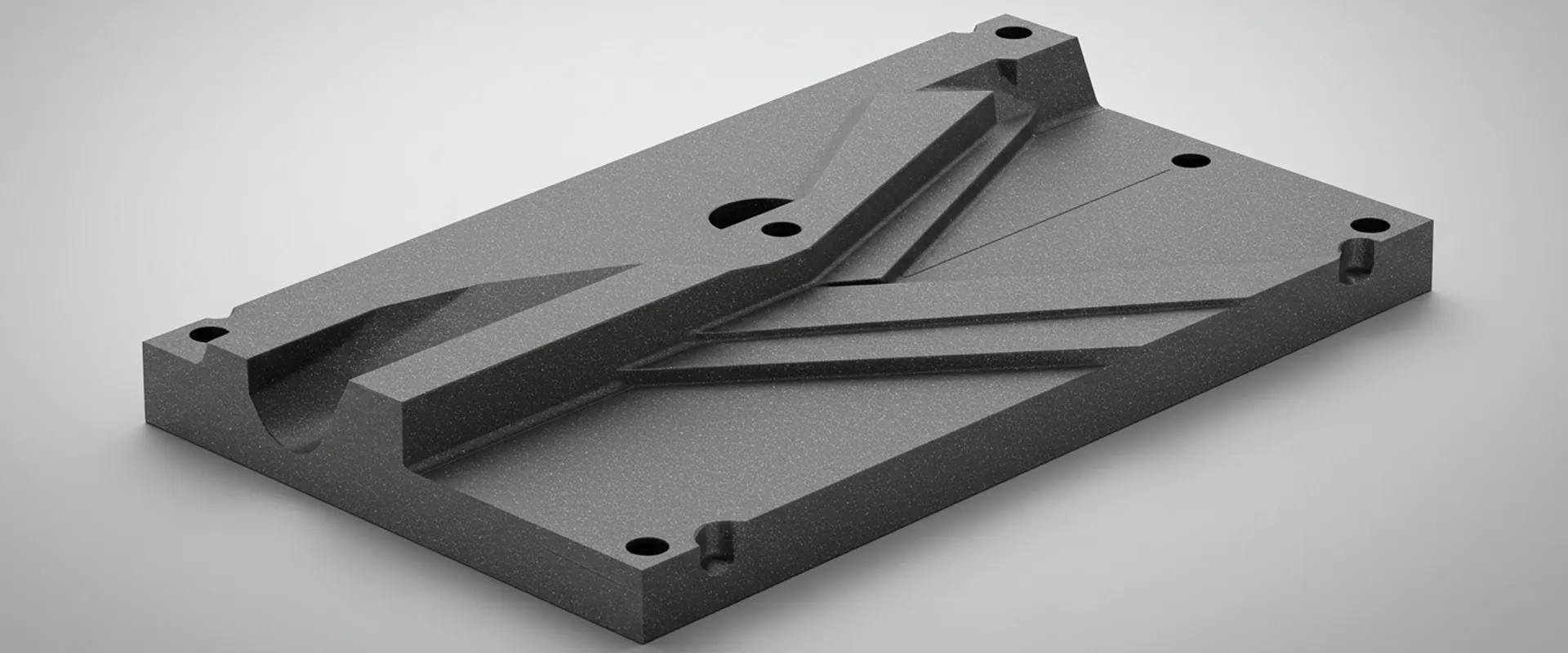

Vacuum molding is a fast, low-cost, small-batch production technology that is widely used in product research and development and prototype production.

-

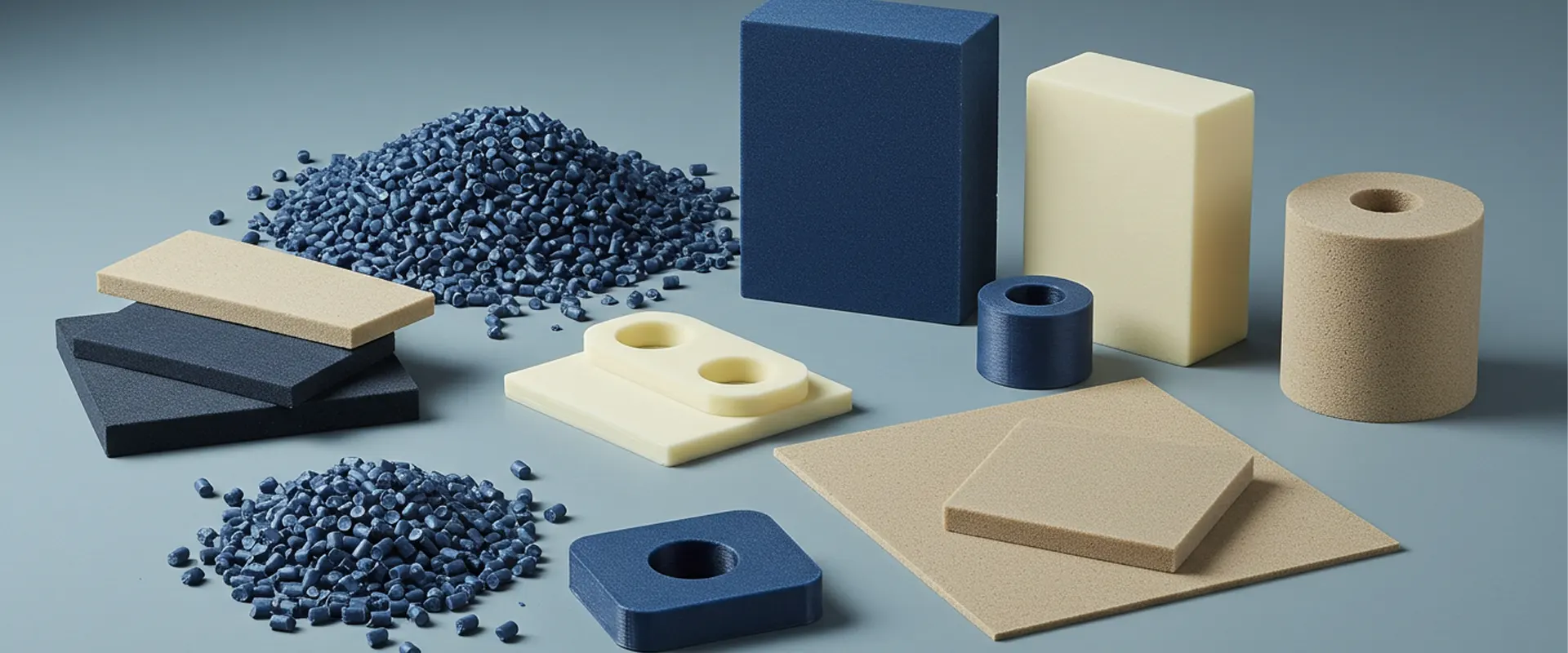

Materials include thermoplastics, silicone, rubber, and more.

-

Advantages are high precision and fast production.

-

Reduces bubbles, defects, with diverse materials.

-

Used in toys, optics, auto, and design.

Vacuum Casting Services

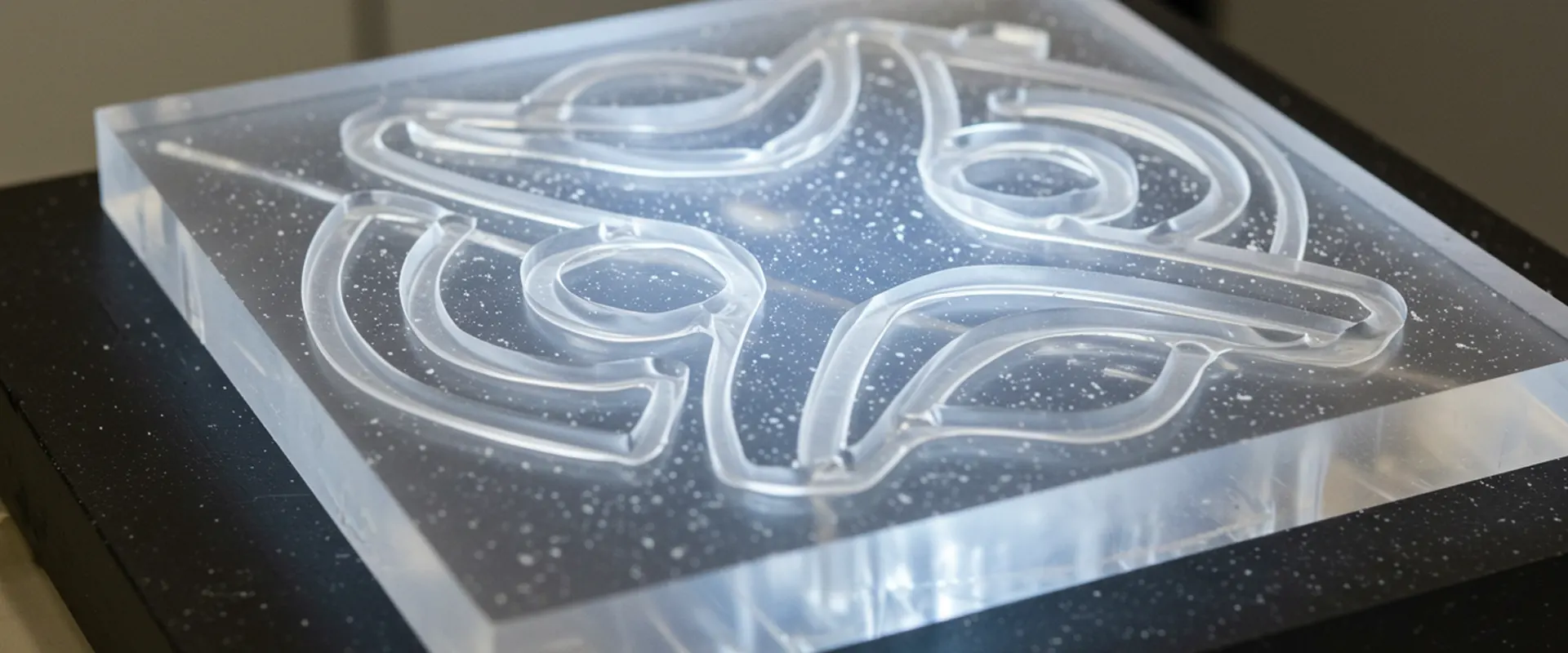

Vacuum casting uses silicone molds to quickly produce accurate plastic parts, ideal for prototypes and small batch production.

Advantages of Vacuum Casting

High Precision & Fine Detail

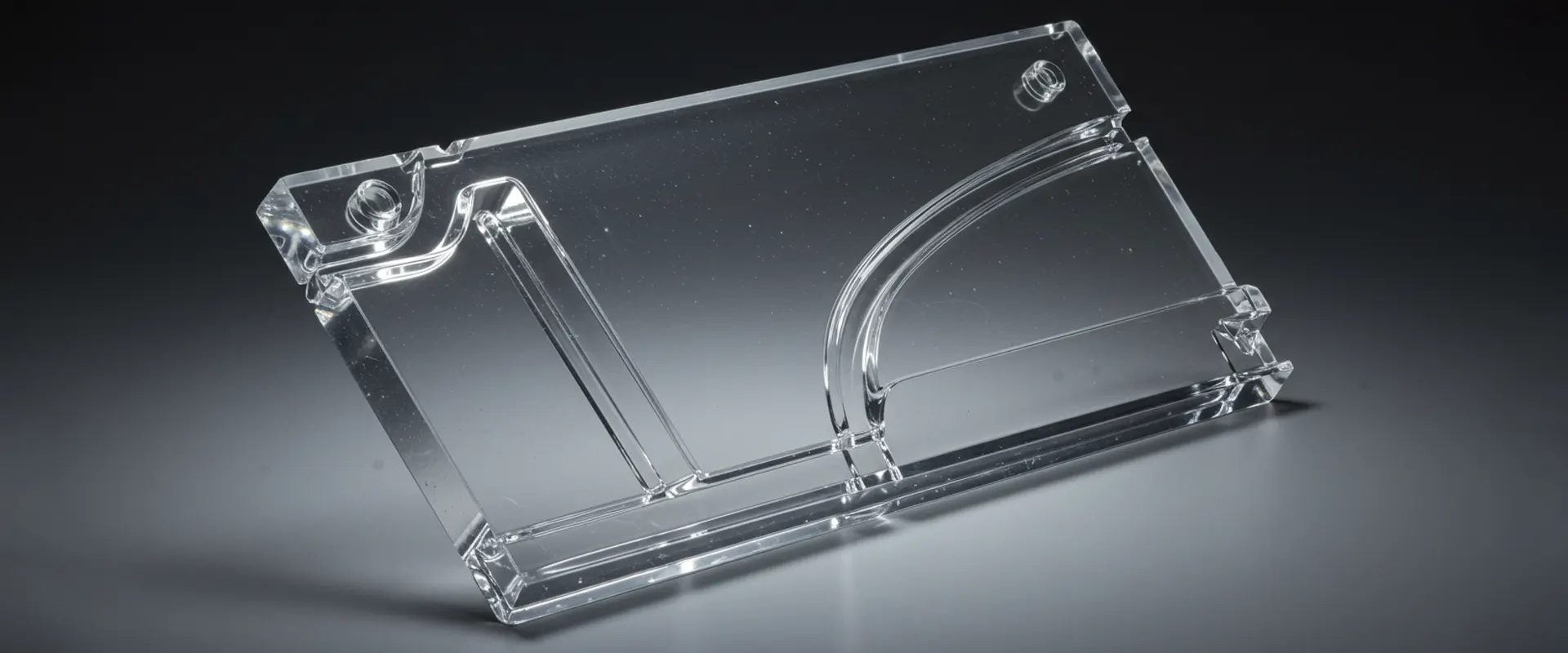

Vacuum casting produces parts with excellent dimensional accuracy and surface detail—closely replicating the quality of injection-molded components.

Fast Production Turnaround

Silicone molds can be completed within days, making vacuum casting ideal for rapid prototyping, functional testing, or small batch delivery on tight schedules.

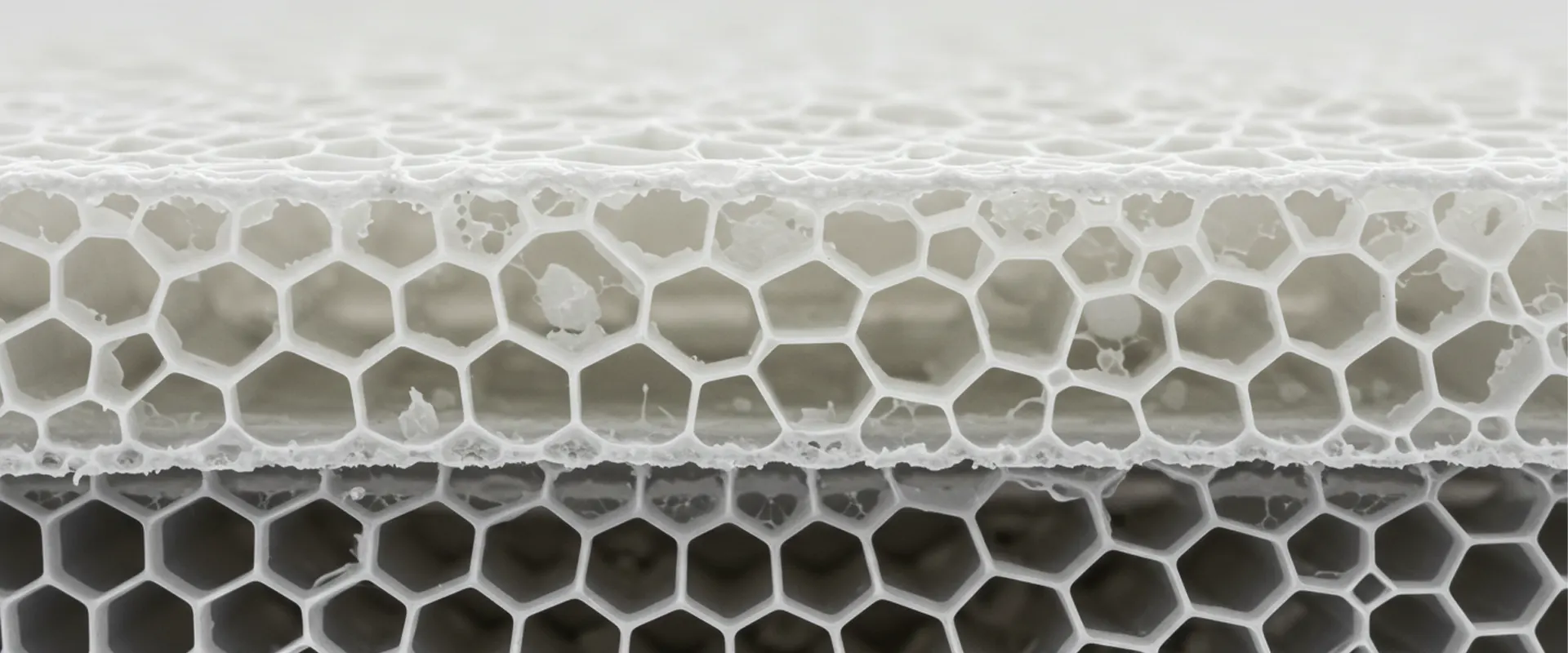

Reduced Bubbles & Defects

The vacuum environment minimizes air entrapment and shrinkage, resulting in smoother surfaces, fewer imperfections, and greater consistency in part quality.

Wide Material Compatibility

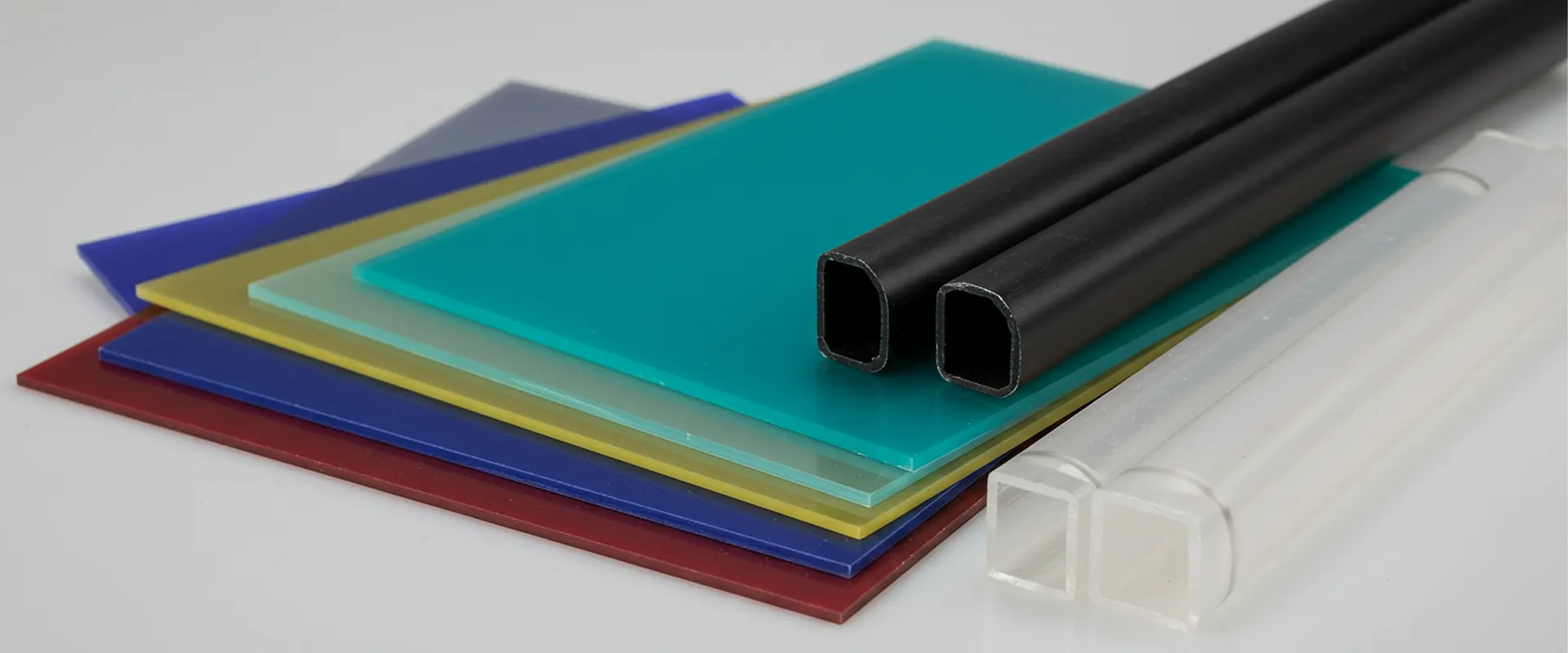

A broad range of polyurethane resins simulating ABS, PP, rubber, and even transparent materials can be used—offering great flexibility in performance and appearance.

Vacuum Casting General Tolerances

For most vacuum cast parts, standard general tolerances typically follow industry best practices unless tighter specifications are indicated on the drawing. Actual achievable tolerances depend on part design, material selection, and the specific casting process used.

| Name | Description |

| Minimum order quantity | 200 runs |

| Mold material | Tool Steel P20, Carbon Steel S50C, Aluminum |

| Mold types | Rapid tooling, production tooling |

| Mold storage | Minimum 2 years and we will do the maintenance for the mold. |

| Mold lead time | 2-3 weeks (Rapid tool), 4-5 weeks (Production tool) |

| Quality assurance | DFM Analysis, Moldflow, CAE, Control Plan, PSW Inspection reports included, full dimensional report and material certifications available upon request, PPAP submitted after starting the production. |

| Sample verification program | Similar to First Article Inspection, you will receive 2 sets of parts upon the machining of the mold to test fit before continuing with full production. |

| Mold remachining | We can remachine the molds should any changes be required, changes to be reviewed on a case by case basis. |

| Reorders | Unit price is based on the quantity required for the reorder with an additional set up fee of $150/€120. |

Part lengths of up to 118" are available on our platform process dependent. Please inquire about anything larger. Tolerances listed here are minimums for an ideal case. Looser tolerances may be required depending on process, material choice, or part geometry. contact us

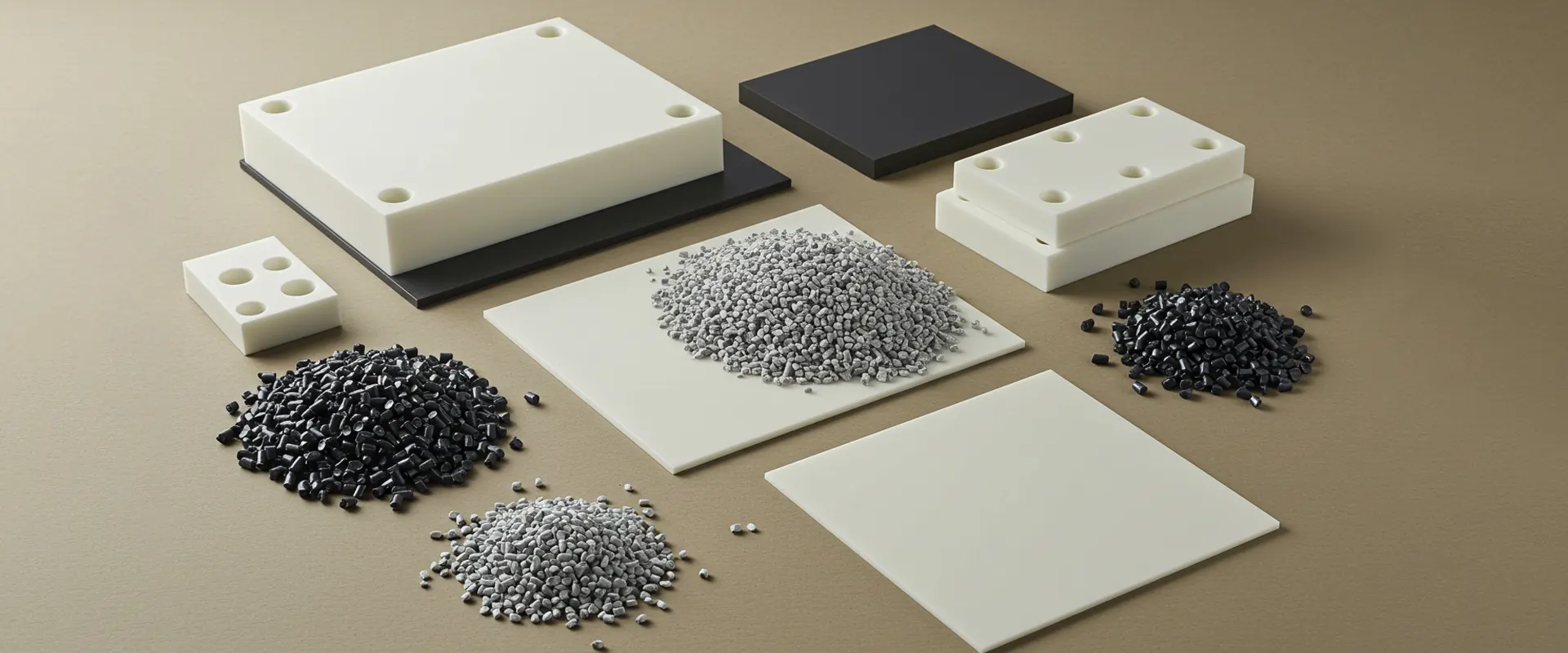

Vacuum Casting Materials

A variety of CNC machined metal and plastic part options are available for an instant online quote.

- ABS

- PMMA

- POM

- PP

- PC

- ABS+PC

- PC+ABS

- Transparent ABS

- Flame-Retardant ABS

- Flame-Retardant PC

- PP+30%

- Brown PMMA

- PE

- Flame Retardant ABS

- Anti-static ABS

- PA+GF45%

- Flame-Retardant PC+ABS

- Food-Grade PC

- PA66+GF15%

- ABS

ABS

ABS is a common thermoplastic known for its toughness and impact resistance. It is available in various colors including gray-white, beige, and black.

Color:

Gray-white, Beige, Black

Density:

1.2 g/cm³

- PMMA

PMMA

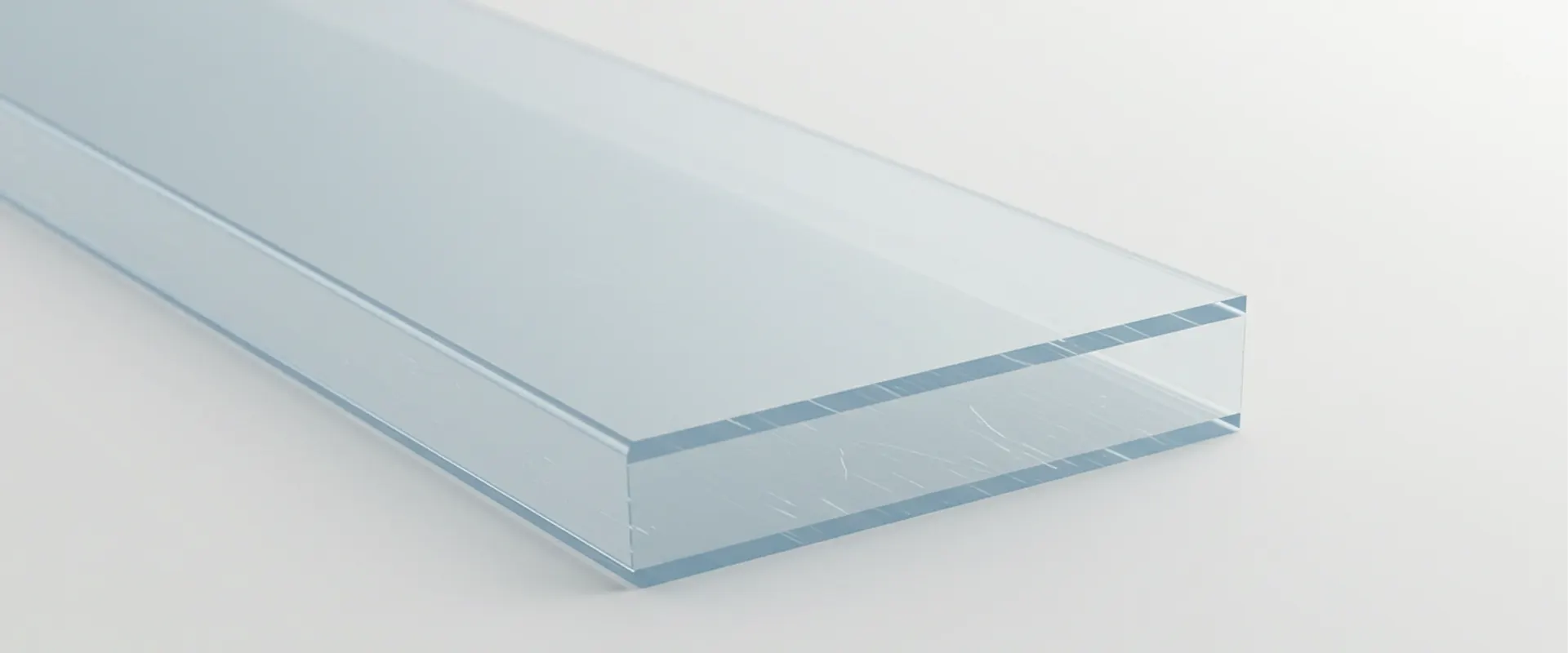

PMMA, also known as acrylic, is a transparent thermoplastic with excellent optical clarity and weather resistance.

Color:

Transparent

Density:

1.2 g/cm³

- POM

POM

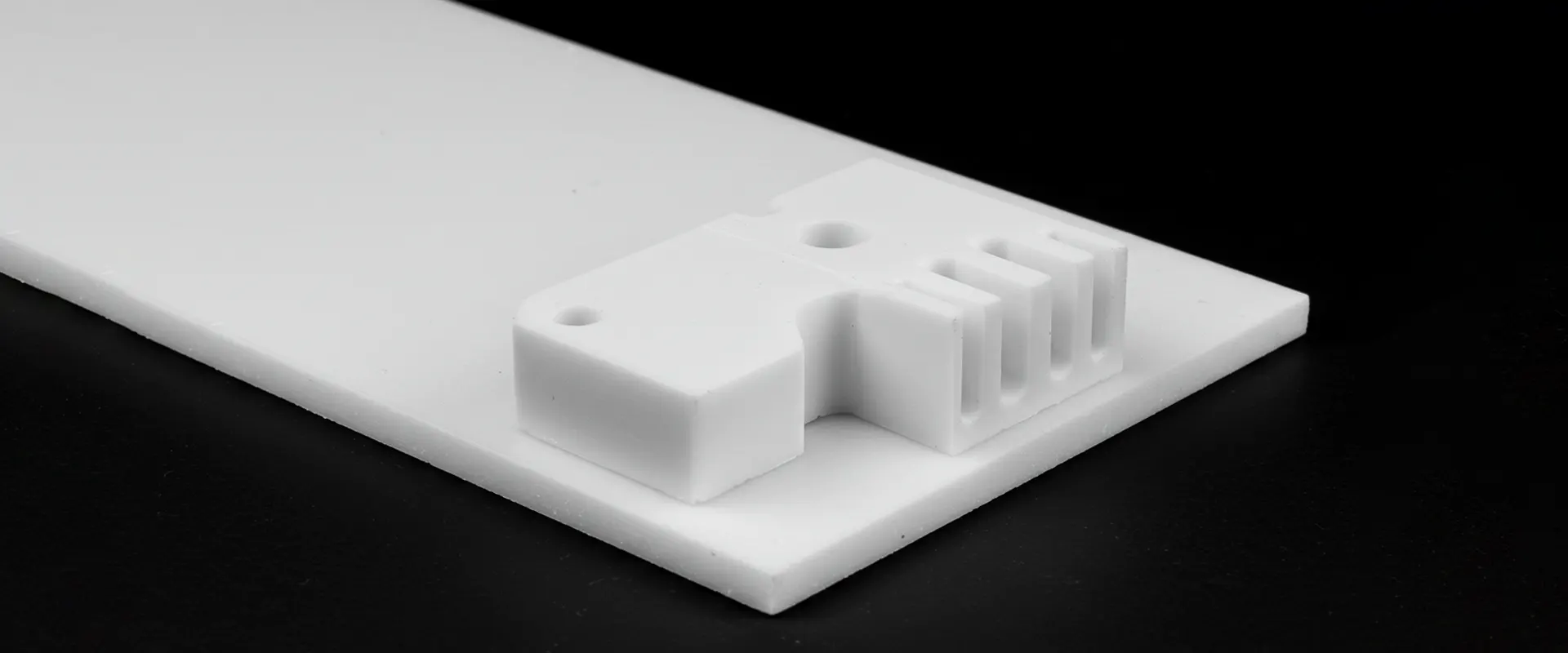

POM, also known as acetal or polyoxymethylene, is a high-strength engineering plastic known for its excellent wear resistance and dimensional stability.

Color:

Black / White

Density

1.4 g/cm³

- PP

PP

PP (Polypropylene) is a lightweight thermoplastic known for its good chemical resistance, flexibility, and low moisture absorption.

Color:

Black

Density:

1.2 g/cm³

- PC

PC

PC (Polycarbonate) is a tough, impact-resistant thermoplastic with excellent transparency and heat resistance.

Color:

Transparent / Black

Density:

1.3 g/cm³

- ABS+PC

ABS+PC

ABS PC material machining is a blend of ABS and polycarbonate, combining toughness, impact resistance, and improved heat resistance. It is widely used in structural components and enclosures.

Color:

Black

Density:

1.3 g/cm³

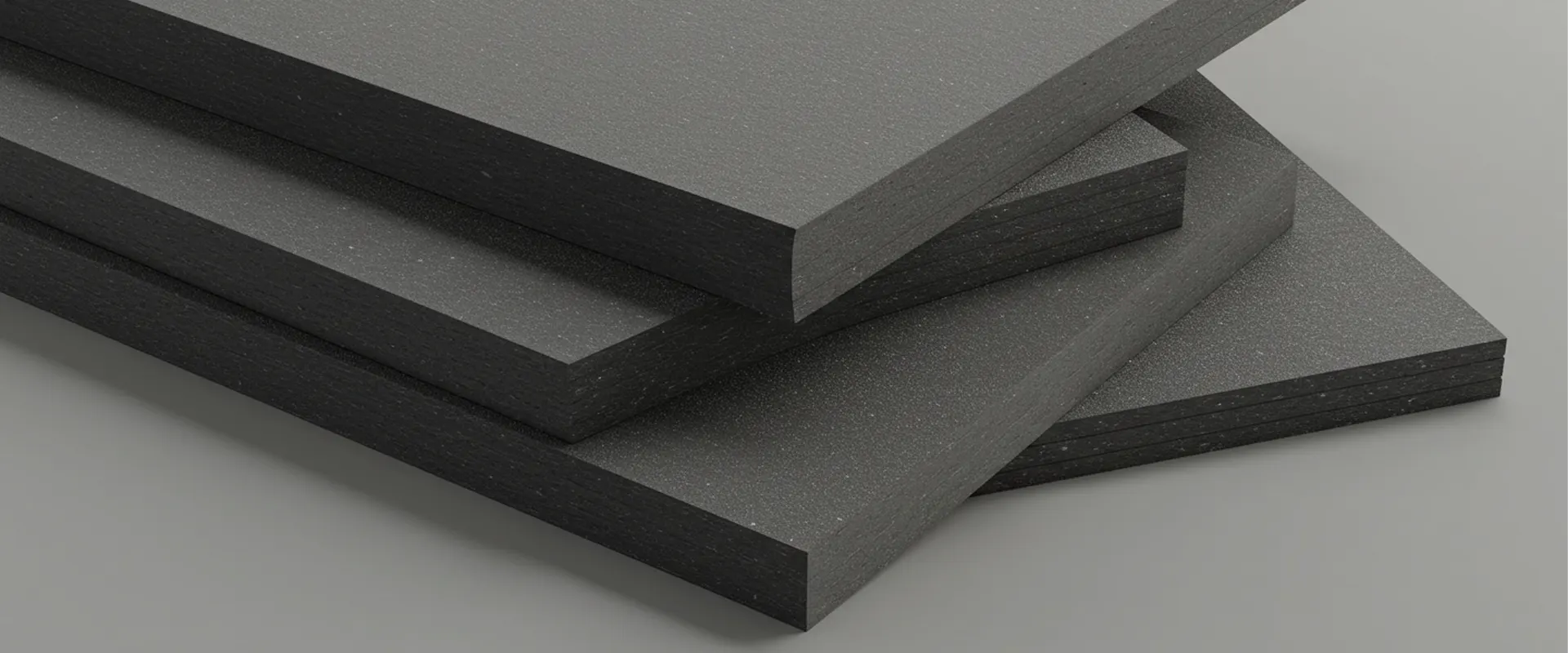

- PC+ABS

PC+ABS

ABS+PC is a blend of ABS and polycarbonate, combining toughness, impact resistance, and improved heat resistance. It is widely used in structural components and enclosures.

Impact Resistance:

High

Heat Resistance:

Better than pure ABS

- Transparent ABS

Transparent ABS

Transparent ABS is a modified ABS plastic with added clarity, offering a balance of toughness, impact resistance, and transparency. Commonly used for visual parts and casings.

Color:

Transparent

Density:

1.3 g/cm³

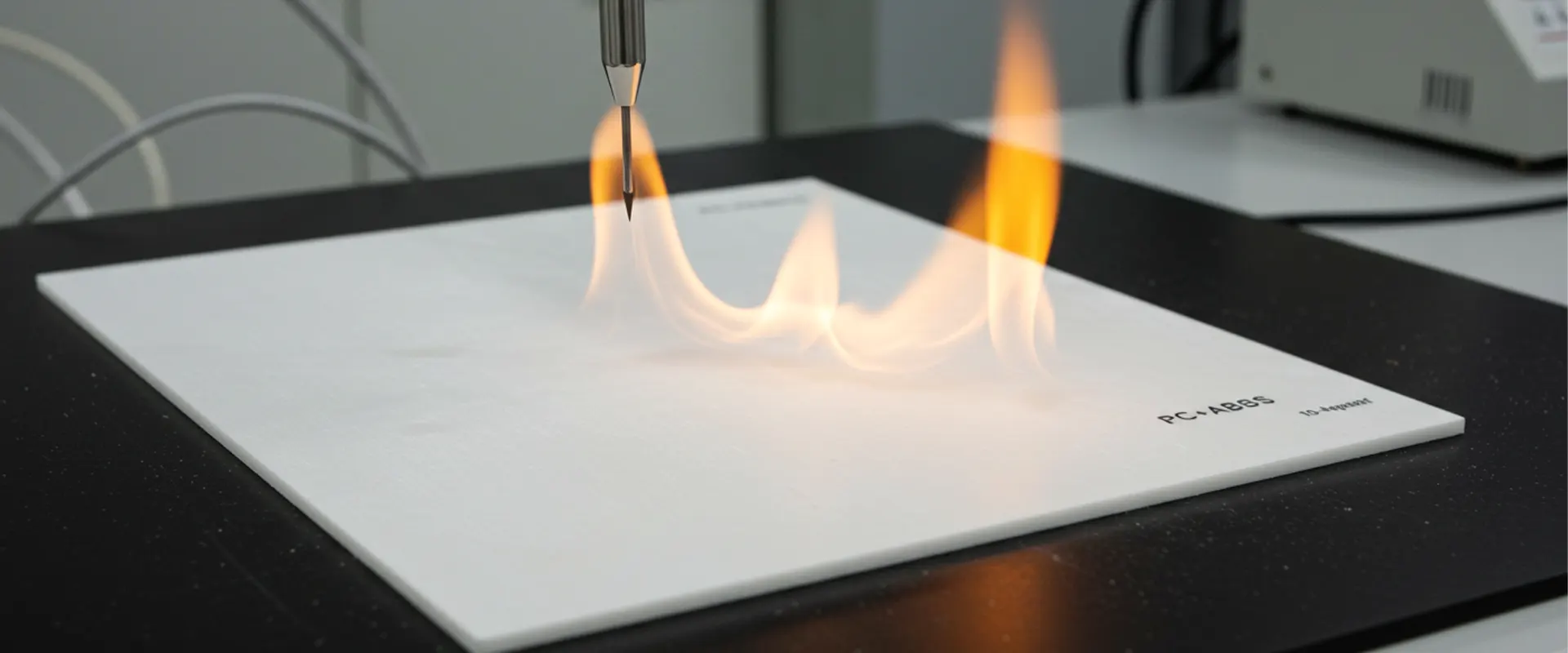

- Flame-Retardant ABS

Flame-Retardant ABS

Flame-retardant ABS is a modified ABS with added fire-resistant properties, commonly used in electronics, appliances, and enclosures requiring safety compliance.

Color:

White

Heat Resistance:

Moderate

- Flame-Retardant PC

Flame-Retardant PC

Flame retardant PC delivers high impact strength, heat resistance, and fire safety—perfect for electronics, automotive, and safety-critical applications.

Impact Resistance:

Excellent

Heat Resistance:

Moderate

- PP+30%

PP+30%

PP+30% is polypropylene reinforced with 30% glass fiber, offering improved stiffness, dimensional stability, and moderate heat resistance. Commonly used in automotive and appliance parts.

Color:

Black

Stiffness:

Enhanced rigidity

- Brown PMMA

Brown PMMA

Brown PMMA is a durable, UV-resistant acrylic with excellent clarity and impact strength—ideal for displays, automotive lighting, and architectural applications.

Density:

1.3 g/cm³

Weather Resistance:

Excellent

- PE

PE

PE is a lightweight, flexible thermoplastic known for its excellent chemical resistance, electrical insulation, and impact strength. It is commonly used in containers, linings, and insulating parts.

Color:

White / Black

Density:

1.0 g/cm³

- Flame-Retardant ABS

Flame-Retardant ABS

Flame-retardant ABS is a modified ABS with added fire-resistant properties, commonly used in electronics, appliances, and enclosures requiring safety compliance.

Color:

White

Heat Resistance:

Moderate

- Anti-Static ABS

Anti-Static ABS

Anti-static ABS is a modified ABS material with conductive additives that reduce surface resistivity, preventing static buildup while maintaining the mechanical properties of standard ABS. Ideal for electronic component housings and ESD-safe tooling.

Color:

Black

Density:

1.3 g/cm³

- PA+GF45%

PA+GF45%

PA+GF45% is nylon reinforced with 45% glass fiber, offering extremely high mechanical strength, stiffness, and dimensional stability. It is ideal for structural, load-bearing, and high-temperature applications.

Mechanical Strength:

Extremely high

Dimensional Stability:

Excellent, minimal deformation

- Flame-Retardant PC+ABS

Flame-Retardant PC+ABS

Flame-retardant PC+ABS is a blend of polycarbonate and acrylonitrile butadiene styrene modified with flame retardants, combining excellent impact resistance, heat resistance, and flame retardancy. It is widely used in electronics housings and automotive interior parts.

Color:

White

Density:

2.1 g/cm³

- Food-Grade PC

Food-Grade PC

Food Grade PC is a tough, transparent, and FDA-compliant plastic ideal for safe food and beverage applications.

Density:

1.2 g/cm³

- PA66+GF15%

PA66+GF15%

PA66+GF15% is nylon 66 reinforced with 15% glass fiber, offering improved stiffness, dimensional stability, and heat resistance compared to unfilled PA66. It is commonly used in automotive parts, electrical housings, and structural components.

Dimensional Stability:

Better than unfilled PA66

If you do not see the material stock you are looking for, please choose "Custom" under the material drop-down on your quote page and submit for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required. contact us

Small Molded Parts within Days

Our complete CNC aluminum service will accompany your aluminum machining project from the prototype construction to the end aluminum parts manufacturing.

Surface Finishing Options

Our comprehensive surface finishing capabilities help enhance both the functionality and appearance of your parts. From basic machined finishes to advanced treatments like anodizing and polishing, we offer a range of solutions to meet different performance, aesthetic, and material requirements.

| Name | Description | Services | Applicable Materials | |

|

Machined Surface | Economical finish left directly from CNC machining, visible tool marks remain. | CNC milling & turning | Metals, plastics |

|

Anodizing | Enhances corrosion and wear resistance; can be dyed, ideal for aluminum parts. | Type II & Type III anodizing | Aluminum |

|

Polishing | Achieves high gloss, reduces surface roughness, and improves metallic aesthetics. | Manual or mechanical polishing | Metals |

|

Sandblasting | Uses pressurized media to clean and texture the surface, creating an even matte effect. | Bead blasting / sandblasting | Metals, plastics |

|

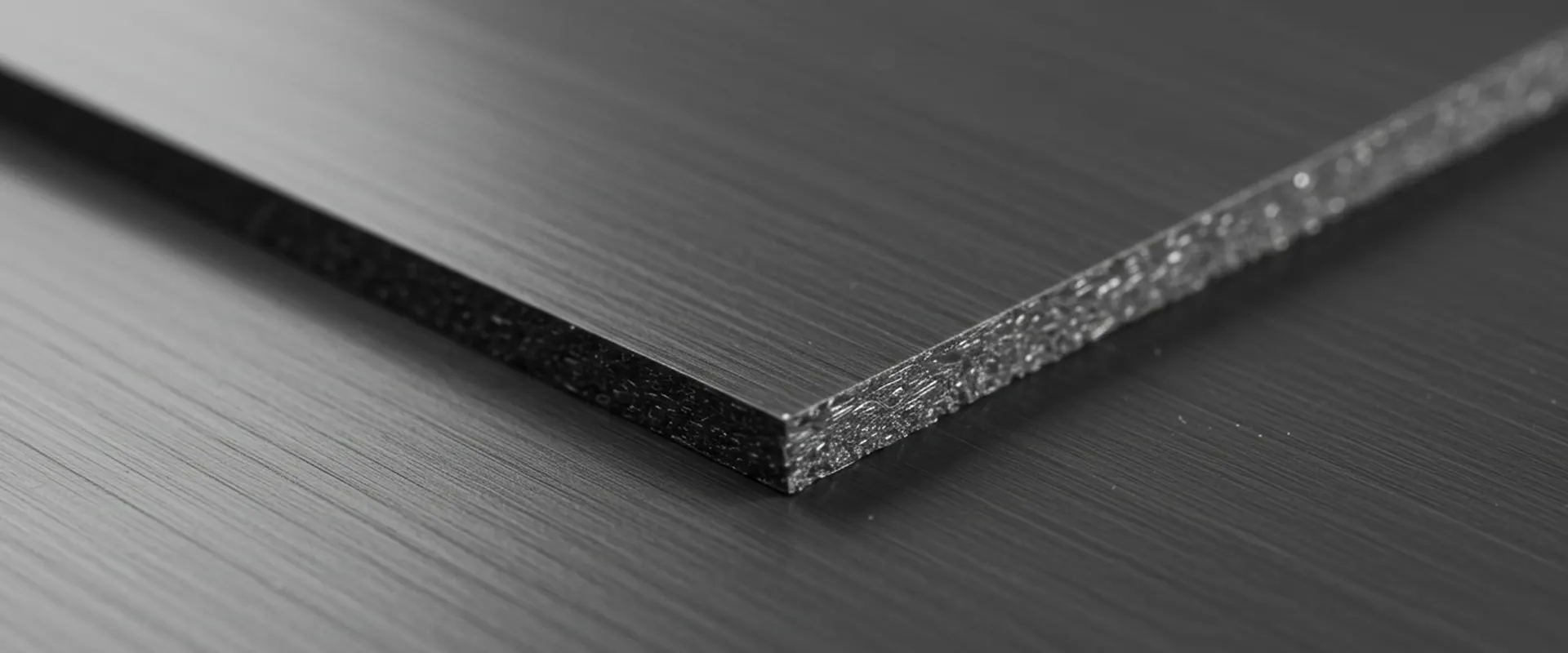

Brushed Finish | Creates a unidirectional satin texture, reducing the visibility of scratches and marks. | Brushing | Metals, some plastics |

|

Powder Coating | Applies a thick, durable, wear-resistant layer with excellent color and texture options. | Electrostatic powder coating | Metals |

|

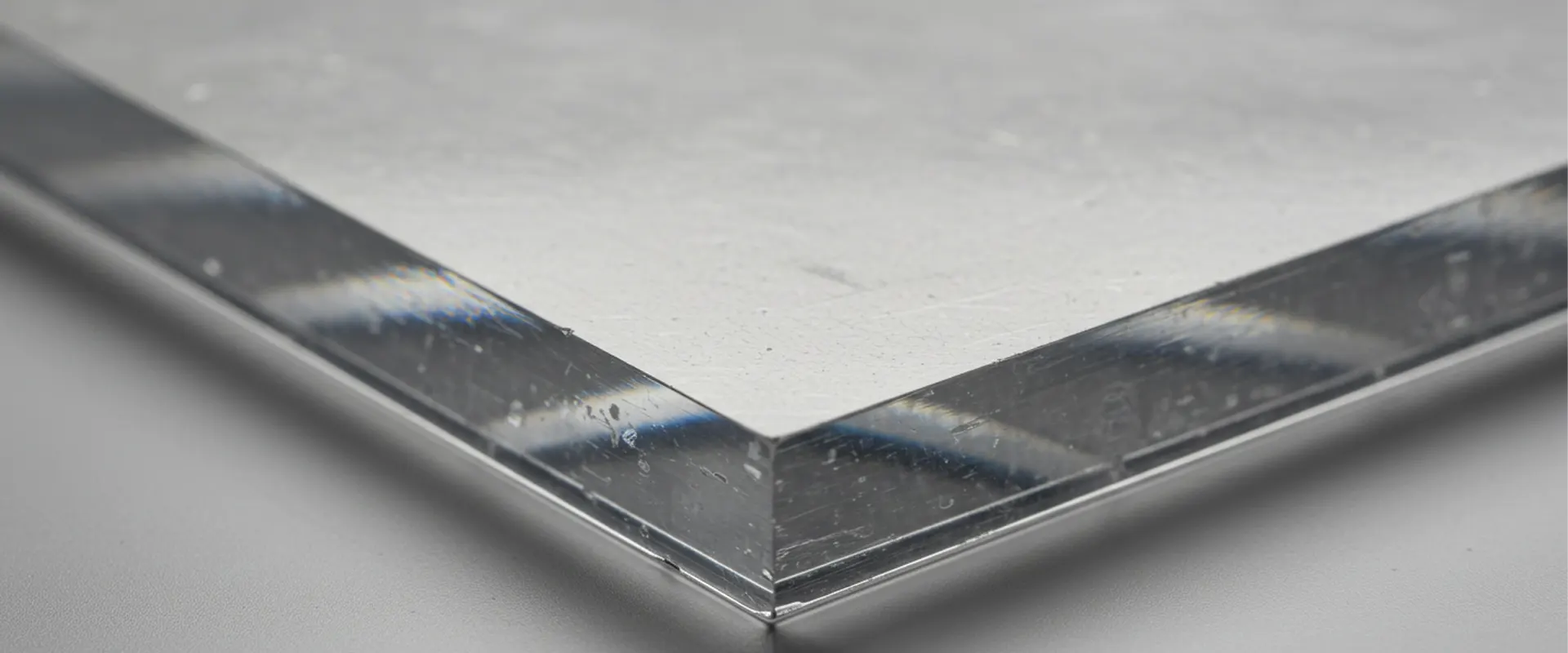

Electroplating | Bonds a thin metal layer to improve wear resistance, corrosion resistance, and surface conductivity. | Chrome, nickel, zinc plating, etc. | Metals |

|

Black Oxide | Conversion coating for ferrous metals that improves corrosion resistance and reduces light reflection. | Black oxide treatment | Steel, stainless steel |

|

Electropolishing | Electrochemical process to smooth and brighten the surface, enhancing corrosion resistance. | Electropolishing | Stainless steel, other metals |

|

Alodine | Chromate conversion coating providing corrosion protection and improved paint adhesion, mainly for aluminum. | Chromate coating (Alodine) | Aluminum |

|

Heat Treatment | Alters mechanical properties, increasing hardness, strength, or ductility. | Vacuum heat treatment, tempering | Metals (steel, aluminum, etc.) |

If you do not see the surface finish you are looking for, please choose “Custom” on the quote page. After specifying features, tolerances, inspection requirements, and quantities, submit for an expert engineering review — or simply contact us for support.

Why Choose GD Prototyping Vacuum Casting?

GD Prototyping offers a fast, cost-effective, and high-quality vacuum casting service tailored for low-volume production. With advanced materials, expert engineering, and flexible finishing options, we deliver precise, reliable parts—on time and to your exact needs.

-

Cost-Effective & Fast Delivery

Vacuum casting offers a highly economical solution for low-volume production with quick turnaround and fast response times.

-

Lower cost than other small-batch methods

-

RFQs answered within 12 hours

-

7–14 day lead time

-

-

Quality & Advanced Tech

Experienced engineers ensure stable quality with near-zero defects. We support complex projects like overmolding and two-color molds.

-

Near-zero rejection rate

-

Overmolding & dual-color casting

-

Full process control

-

-

Material & Finish Flexibility

We use certified imported materials and offer a wide range of surface finishes to meet both visual and functional needs.

-

High-grade materials with reports

-

Painting, silk screen & more

-

One-stop post-processing

-

Join Over 3,000 Companies Using GD for Quality Parts

Explore real-world case studies from our customers that showcase the power of our manufacturing capabilities to drive product development.

An Engineering Show For Product Developers

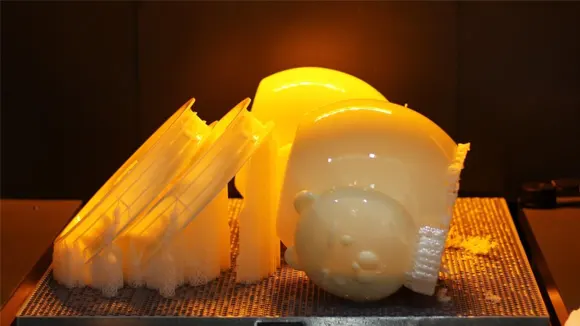

Vacuum casting is a good option in the creation of high-quality prototypes and low-volume end-use components. GD Prototyping has the capability to provide you with the necessary number of samples to test or several hundred parts to introduce into the market with the required flexibility of vacuum casting.

-

Injection-Molding-Level Precision

Vacuum casting delivers high-fidelity prototypes with fine surface detail and dimensional accuracy—ideal for fit, function, and visual validation.

-

Rapid, Low-Cost Production Runs

With fast mold creation and material versatility, it’s a cost-effective solution for low-volume production and market testing.

-

Flexibility in Design and Finishing

From overmolding to multi-color parts, and with a wide range of post-processing options, vacuum casting brings your design vision to life quickly and accurately.

Frequently Asked Questions

Here are answers to common questions about industrial PCs and automation solutions. Need more details? Contact our experts at sales08@gd-prototype.com

-

What services does GD Prototyping offer?

-

What industries do you serve?

-

What materials can you work with?

-

How fast can I get a quote?

-

What’s your typical lead time?

What Our Customers Say

Customized Process

Having years of manufacturing experience, GD Prototyping offers the optimal solutions to all rapid prototyping and low-volume manufacturing requirements. We reduce the innovation cycle into four easy steps but effective.

Flexible Design Iterations

Creating low volume manufacturing allows for more efficient verification of design, engineering and manufacturability.

Short Turnaround Times

Tooling is cost-effective for low volume manufacturers to handle orders quickly and flexibly, with no minimum order quantities.

Close the Production Gap

Low-volume pilot runs bridge the gap between prototype and production, identifying and resolving any issues before entering series production.

Reduced Time to Market

Low-volume manufacturing services optimize the connection between production, supply chain and consumers, providing fast time-to-market for new products.

Get Your Parts Into Production Today

Our complete CNC aluminum service will accompany your aluminum machining project from the prototype construction to the end aluminum parts manufacturing.

At GD Prototyping, our Vacuum Casting services are designed to deliver high-quality prototypes and low-volume production parts with exceptional accuracy and surface finish. This process uses silicone molds and polyurethane resins under vacuum conditions to replicate complex geometries with fine detail, closely matching the look and performance of final products. Vacuum casting is especially effective for short-run batches where injection molding may not be cost-efficient. It provides a versatile solution for functional testing, design validation, and marketing samples, offering consistency across multiple parts. By simulating production-grade plastics and rubber, it allows clients to assess product usability before committing to mass production. With fast turnaround times and excellent cost-effectiveness, GD Prototyping ensures that every vacuum-cast part aligns with client requirements, helping businesses accelerate product development and bring innovations to market with confidence.

Applications of Vacuum Casting

- Prototyping – Produces functional prototypes that mimic injection-molded parts.

- Small-Batch Production – Ideal for runs of 20–100 units at lower costs.

- Medical Devices – Creates housings and components with detailed precision.

- Consumer Products – Delivers casings, enclosures, and pre-market samples.

- Automotive Industry – Provides custom interior parts, covers, and housings.

- Electronics – Manufactures connectors, buttons, and panels with fine finish.

- Design Validation – Enables engineers to test fit, form, and function before tooling.

- Marketing Samples – Produces realistic models for presentations and trade shows.