Stainless Steel 304 Machining | CNC Manufacturing Experts

Introduction

Stainless steel 304 machining is an aid in precision engineering. The 304 (also referred to as 18-8) stainless steel is an amalgamation of resistance to corrosion, strength, and versatility. As mentioned, grade stainless steel 304 is the most common variety. Still, it does not imply that it is simple to machine 304. It gets hardened soon and generates heat. But, when correctly machined, i.e., with the correct tooling, parameters, and cooling, then you have extremely beautiful elements that are long-lasting. Precision CNC machining of 304 stainless steel is our niche in GD Prototypes. Just like our standard parts, our custom parts are well-tolerated, mirror-finished, and well-finished.

How to Know 304 Stainless Steel: Material Basics

Composition & Properties

The stainless steel 304 is a form of austenitic iron which has a composition of about 1820 chromium and 8 10.5 nickel. It is annealed non-magnetic, and is of many varieties of corrosive resistance. Mechanical characteristics (significant typical values):

- Ultimate tensile Strength: = 510 Mpa

- Yield Strength: ~ 215-220 MPa

- Hardness (approximately): Rockwell, the order of 70 BHN (converted scale)

Parameters and Strategies of Machine 304 Stainless Steel

Machine 304 needs a process that involves turning, milling, drilling, and finishing to machine it. The following are some of the proposed parameters and tips.

Turning (Lathe/CNC Turning)

Normal cutting speeds of 160-215 m/min ([?] 520-710 SFM) are used in the case of turning 304 stainless to operate on a stable machine. The feeds cannot be either too slow or too fast, as this promotes hardening of the work or excessive speed, which is overloading the tool. Cuts are of shallow depth. Tools have carbide inserts that are coated appropriately. General instructions for the source of stainless steel turning:

- Positive rake angles (less cutting forces), no deep cuts on finishing passes.

- Avoid chatter through the use of a coolant and a good tool geometry.

Milling/CNC Milling

It provides a smaller cutting speed in milling 304 compared to turning, due to the higher engagement and chip thickness. Milling, Stable clamping, and short tool overhang are all handy in milling.

Typical Recommended Ranges:

- When the milling is performed under constant conditions on the milling of 304 stainless steel, 100-135 m/min ([?] 330-440 SFM) is needed.

- Use good cutters that have cutter coating composed of carbide.

- Mean depth of cut in the axial and radial direction.

- Push chips are usually a favorable choice in comparison with climb milling.

Drilling & Hole Work

The 304 stainless steel is less conservative in the parameters used when drilling. As was discovered in the research, the optimal combination is: 800 RPM spindle and 12 mm/min feed with the drilling of the helix angle of 25deg because it gives a good surface finish. Peck drilling cycles are applied to stop the binding of chips in deep holes.

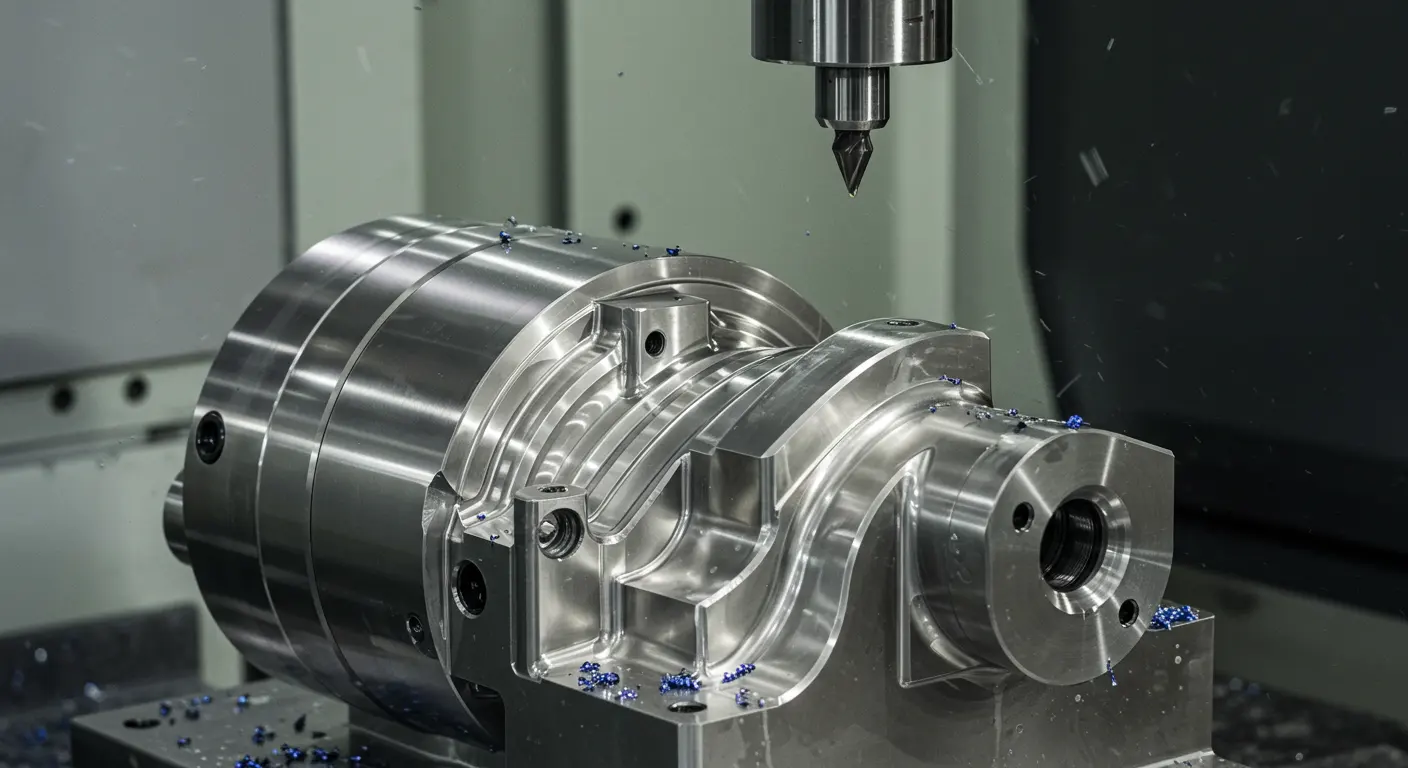

314 Stainless Steel Parts CNC Milling: The Accuracy, Performance, and Perfection

The 314 stainless steel components are machined in CNC machines that offer unmatched precision, strength, and resistance to corrosion for high-demand components. The newest CNC milling and turning technology has been employed in GD Prototypes to ensure that all production batches have micro accuracy (+ -0.01mm). Whether it is 10 or 1,000, every part is identical in regards to size, position of holes, and finish.

The high-speed CNC machine tools allow a roughness of surface of Ra 0.8mm or less and should be used in the industries where high smoothness and wear life are a necessity. Furthermore, the appearance of all the machined elements and their corrosion characteristics are further improved with after-processing techniques, such as polishing, deburring, and electropolishing.

Multipurpose Material Performance

We also have CNCs that can machine a wide range of materials that include alloy aluminum, copper, carbon steel, and titanium alloys. Every material is selected based on some performance requirements, such as corrosion, mechanical, heat, or weight performance. This flexibility will provide us with the competence to serve a great variety of industries, including aerospace and automotive, medical equipment, consumer electronics, and automation systems.

Why Choose GD Prototypes Machining?

GD Prototypes has more than 300 qualified professionals, a facility of more than 12,000 square meters, and is an ISO-registered, award-winning manufacturer of CNC machining, rapid prototyping, and low-volume production. We are proposing the turnkey project management, and this will give a smooth flow from design to delivery.

It may be high-quality stainless steel complex assemblies, or it may be very precise custom assemblies. GD Prototypes is a combination of engineering skills, the latest technology, and high-quality control to achieve high results every time.

- Tooling, Insert Choices, and Geometry.

- One must always choose the appropriate tooling.

- Tool Materials & Coatings

- Inserts are of a carbide type. Introduce thermal and wear-resistant layers (e.g., TiAlN, CVD, PVD).

- The cutting forces are reduced by tools with positive rake angles, which enhances chip flow.

- Honing edges provides the edge protection of 304 machining against a rough environment (0.03-0.05 mm).

Geometry & Insert Features

- Use chip breakers to cut the chips into manageable lengths.

- Enough relief angles must be offered to avoid rubbing.

- Very large overhangs or tool extensions are also unwanted -it is the stiffness that counts.

Tool Life & Wear

Tool wear is caused by heat and brutal contact. Temperatures at the insert edge were as high as about 650 °C, and cutting forces were up to about 750 MPa at 0.3 mm depth of cut and 200 m/min in one simulation study. It has caused the importance of good cooling and keeping the cutting conditions constant.

Applications & Use Cases

Stainless steel 304 Machining is applied in a large range of industries:

- Food/beverage equipment- due to corrosion resistance.

- Medical tools & equipment - glassy smooth, delicate shape.

- Architectural / decoration aspects -- stainless finishes are polished.

- Gears, industrial-use: brushings, housings, brackets.

- Car components, some exhaust components, and decoration.

During the design, make sure you design the holes, the thickness of the walls, and the fillets in a manner that they can be machined.

The Significance of Selective 304 Stainless Machining

All machine shops are familiar with the peculiarities of 304 stainless. At GD Prototypes, we bring:

- Numerous experiences in machining 304 stainless steel CNC.

- Optimized and tested libraries of parameters.

- ISO-quality control systems

- Fluent service: mass production on prototyping.

- Custom part design advice and support.

You do not need to make costly errors, broken equipment, or an ineffective part once you are one of our associates.

Future Trends & Innovation

A Shifting World: Stainless steel 304 machining. Hybrid manufacturing Hybrid manufacturing Additive (3D printing) and subtractive machining.

Smart Tooling/Sensors: Real-time feedback to effect change in the speeds/ feeds.

Green Coolants: Coolants are environmentally friendly, and they do not lose their performance.

Optimization with AI on the Fly: Self-learning algorithms.

We have led the pack in terms of investment in new tooling, training, and automation in our GD Prototypes.

Conclusion

Stainless steel 304 machining must be treated with respect. It is not the easiest alloy to cut, and once more, it requires the appropriate knowledge to have components that will pass the time test. And every step is significant, it is the selection of cutting speeds and feeds, the choice of carbide inserts, the management of chips, or the management of finishes on the surface. The machining of 304 stainless parts and precision is all about GD Prototyping. And we will render your design true to life, precise, gorgeous, and strong.