Small Batch 3D Printing Services | Cost-Effective Production

Small Batch 3D Printing Rapid, Economic, and Efficient

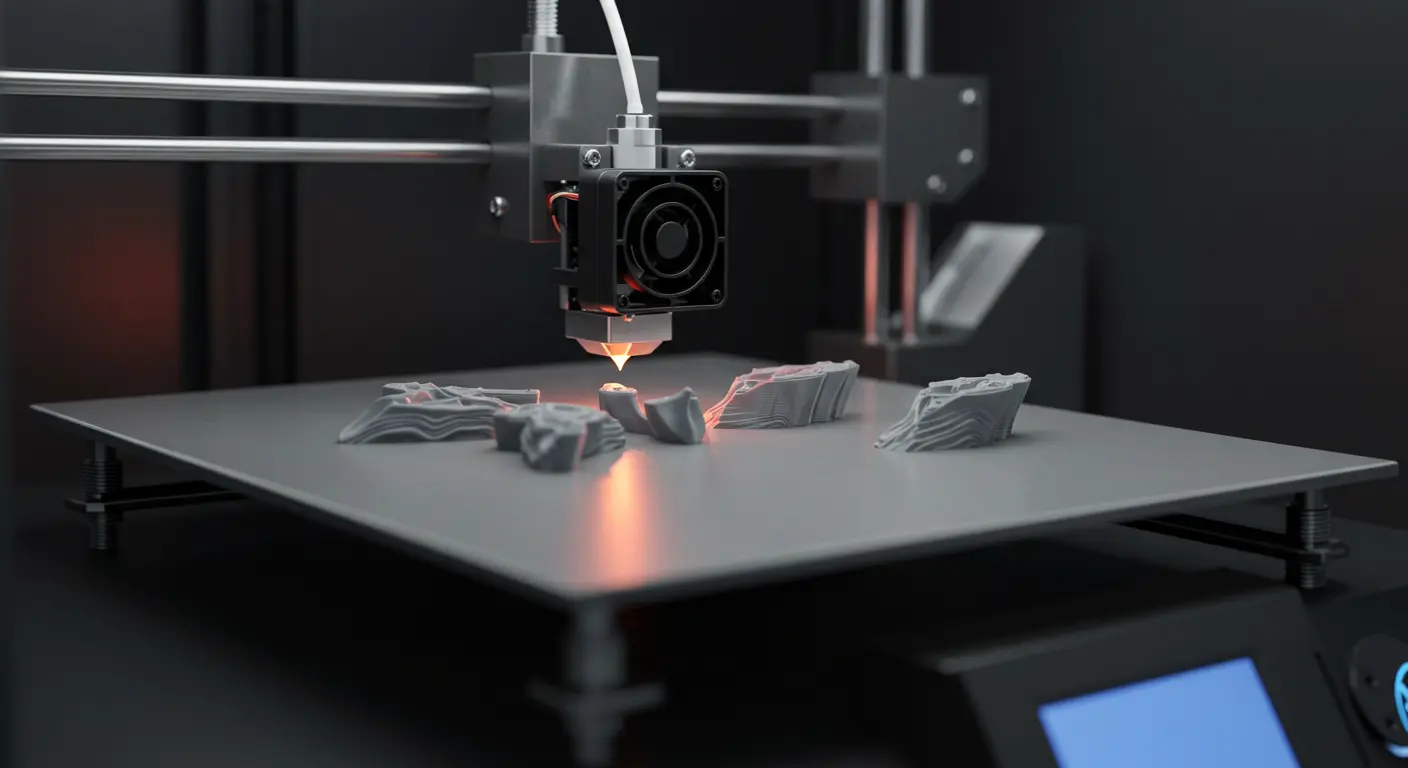

Small batch 3D printing helps the manufacturers produce small quantities of components in a short duration and at low cost, and this can be accomplished within days and not months, as in the case of conventional practices. Additive manufacturing (AM) in low-volume production is not only faster but also smarter, and that is flexible and efficient for businesses having specific production needs.

The current-day industry only requires the production of parts, after-market automotive parts, and consumer custom products. A case in point is that of a luxury/custom car manufacturer that will only need a few spare parts. Such low-volume demand is not normally a viable and economically feasible investment to place in a full-scale production line. The most suitable area where additive manufacturing applies is in low-volume production.

The Key Advantages of Small Batch 3D Printing

Speed of Production: Produce working parts in days instead of months.

Economy of Tolls: There is no necessity to pay the high start-up cost of traditional tooling or molds.

Custom Solutions: Ideal: with after-market components, prototypes, or custom parts.

Flexible Manufacturing: It is flexible to changes in design or prototype.

High Precision: Achieve small tolerances and smooth finishes on surfaces.

Material Variety: Plastics, metals, and composites are used to assist the demands of different performances.

Rapid Quotation and Stable Lead-Time are Present at GD Prototypes

At GD Prototyping, we understand the significance of low-volume production and quick prototyping:

Fast Quotation: The engineering department can quote a fast prototyping in 6 hours.

DFM Analysis: Design-for-Manufacturing (DFM) analysis is an aspect of the production project to enable it to be viable.

Constant Lead-Time: We are oriented towards rapid prototyping, and we do not compromise the quality since we understand that the most significant part of rapid prototyping projects is the lead time.

Customized Solutions: be it a design of automobile parts or an engineering prototype, we are providing cost-effective and reliable manufacturing solutions.

The most appropriate one is small batch 3D printing, where a business will need large quantities of components that will be produced quickly and low cost. Incorporating hi-tech additive manufacturing with a mix of know-how engineering services, GD Prototypes has delivered precision parts at the correct place and at the appropriate time within a budget.

What is it?

Small batch 3D printing refers to the production of a few parts, by additive technologies of production, rather than by the old-fashioned mass production of parts. Small batch production also relies upon the flexibility, customization, as well as speed, as opposed to large-scale manufacturing that relies on injection molding or CNC machining thousands of parts at a time.

This approach is ideal for:

- Development and prototyping of products.

- Pilot production runs

- Specialized purpose industrial aspects.

- Validation and design testing.

With CNC and additive hybrid manufacturing, GD Prototypes will obtain high tolerances and consistent finishes on surfaces irrespective of the volume quantity.

Technologies

These 3D printing processes consist of some different additive manufacturing processes, all of which are suitable for specific materials and requirements:

SLA (Stereolithography)

Its SLA uses curing of liquid resin in layers with the assistance of the laser to produce smooth-surfaced and high-resolution components. It is most effective with prototypes of high detail, medical equipment, and complex components.

Selective Laser Sintering (SLS)

SLS 3D printing entails mixing of powdered substances such as nylon or composite to produce parts. It allows high-strength, functional components that may be applied in aerospace and automobile applications. GD Prototypes is a business that specialises in the manufacture of tough, finished components in small batches.

FDM/FFF (Fused Deposition Modeling)

They refer to a layer-by-layer extrusion of thermoplastic filaments. It is cost-effective as far as functional prototyping and low-volume plastic parts are concerned.

Metal 3D Printing

Small batch production of high-strength components: Metal additive manufacturing is most appropriate in high-strength component production of stainless steel, titanium, or aluminum alloy. The outcome of such processes is high tolerances and high material performance.

The Key Advantages

Rapid Turnaround

It reduces the lead time as opposed to the lead time in conventional manufacturing. One can reuse designs, experiment, and improve them quickly without tooling delays.

Low Volumes Economical

The traditional methods require molds or a large setup cost of set up. Small batch production does not require initial large tooling costs, and thus it is applicable when carrying out pilot runs or projects.

High Precision and Quality

It is high quality and precise with tolerances of +-0.1mm, post-processing, like polishing, deburring, and electropolishing, and high layer resolution.

Material Flexibility

3D printing has the potential to accept plastics, metals, composites, and resins, such that it can support components with a given strength, corrosion resistance, or light weight.

Individualization and Multidimensionality

They can be easily fabricated into complicated designs and complex geometries that would have been difficult to produce in a conventional manufacturing process, e.g., inside channels, lattices, and multi-material assemblies.

Its Applications in Industries

There are several uses of small batch 3D printing in industries, which provide structural, reliable, and accurate parts:

Automotive: Special parts, prototypes, and low-volume assemblies.

These Applications Aerospace: Light-weight high-strength in functional testing and pilot production.

Medical Devices: Implants, which are customized to a patient, surgical guides, and diagnostic components.

Consumer Electronics: Little volume production of housings, connectors, and components.

Mechanical Custom Gears, Couplings, and Modules

Small-scale 3D printing could be utilized to identify the ineffectiveness of designs and reduce the risk to manufacturing in startups/ business enterprises with small production runs.

Processing and Finishing Methods

When 3D printed by small bi-dimensional parts, they can be subjected to various finishing processes to improve the quality of the surface, dimensional accuracy, and aesthetic appearance:

Polishing and Deburring - removes sharpness and improves feel.

Electropolishing - heightens corrosion and smoothness of the surface.

Painting and Coating - accepts custom colors or handy finishes.

Heat Treatment- hardens and increases the durability of metal parts.

These finishing processes ensure that all the parts are already finished, operable, and not displeasing to the eye.

Choosing a 3D Printing Service Provider (Small Batch)

The selection of a desirable service provider is a significant move towards quality, consistency, and delivery within the required time. GD Prototypes offers:

- Consultancy for a construction turnkey.

- The ISO certified quality control and inspection.

- Low-volume manufacturing, pilot manufacturing, and quick prototyping.

The choice of materials, optimization of designs, and finishing are advised by a professional.

Green and Cost-Effective Production

Additive 3D printing of small batches also reduces waste in comparison to subtractive manufacturing. It helps the manufacturers to produce only the demanded products, lessening the expenses of materials and polluting the environment. This sustainable approach conforms to the present-day goals of manufacturing, especially start-ups and ethics-based industries.

Conclusion

Small batch 3D printing is highly accurate, flexible, and efficient, and a modern solution to low volumes of production requirements. GD Prototyping is also involved in offering high-quality, reliable, and custom parts and components in other industries in regards from rapid prototyping to high-end use parts. By employing the most recent additive manufacturing techniques, high-precision, and professional post-processing, we will make sure that all small-batch orders are manufactured to the best standards. To win the trust of 3D printing services, check out GD Prototyping and see how our expertise can accelerate your product development and small lot production.