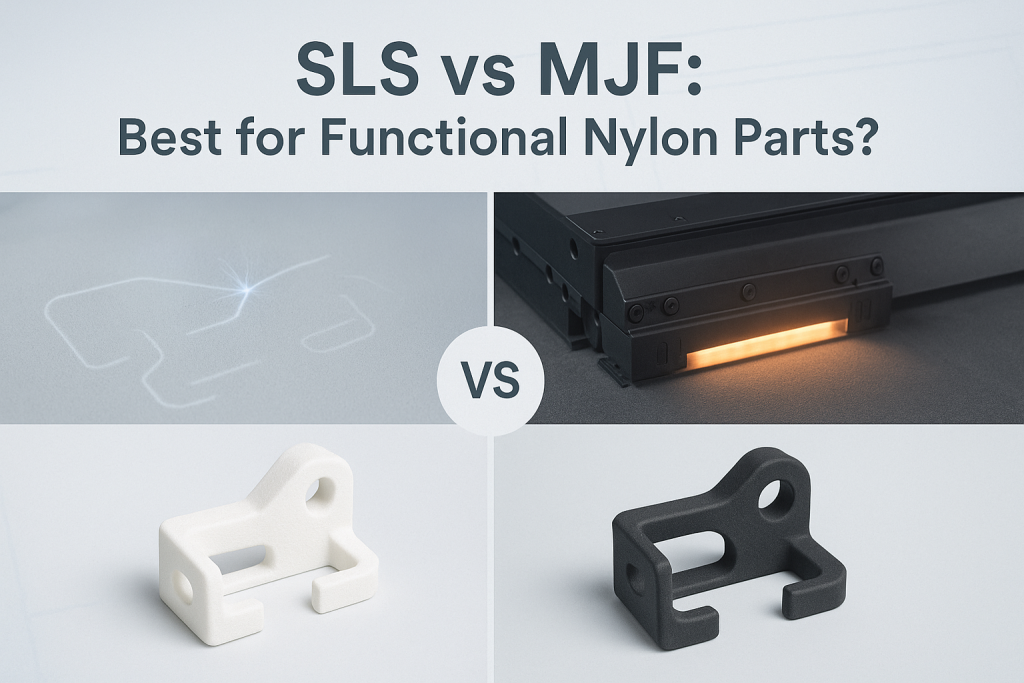

SLS vs MJF: Best for Functional Nylon Parts?

In the world of industrial 3D printing, two technologies stand out for producing strong, durable, and complex nylon parts: Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF). Both are powder bed fusion processes. They create parts from thermoplastic powders without the need for support structures. This capability gives engineers immense design freedom. However, these two technologies are often misunderstood or seen as interchangeable. While they produce similar parts, the underlying processes are fundamentally different. These differences have significant implications for a part's properties, cost, and production speed.

The main difference is the energy source used for fusion: SLS uses a CO2 laser to sinter powder point-by-point, while MJF uses an inkjet array to apply a fusing agent and an infrared lamp to fuse an entire layer at once. This distinction makes MJF a generally faster process, especially for volume production, while SLS offers a broader range of materials.

As an expert service provider with both SLS and MJF technologies in-house, GD-Prototyping offers this unbiased, deep-dive comparison. This guide will provide the technical clarity needed for engineers, designers, and project managers to make the optimal choice for their functional nylon parts.

The Foundation: What is Powder Bed Fusion?

To understand the nuances between SLS and MJF, it is essential to first understand the technology family they both belong to: Powder Bed Fusion (PBF). PBF processes share a set of core principles that give them their unique advantages.

Understanding the Technology Family

All PBF processes build parts within a build chamber filled with a fine polymer powder. The process works layer by layer:

- A thin layer of powder is spread across a build platform.

- A thermal energy source is used to selectively fuse the powder particles together, creating a solid cross-section of the part.

- The platform lowers, and a fresh layer of powder is applied.

- The process repeats until the entire part is fully formed.

The most significant advantage of this method is that the surrounding, unsintered powder acts as a natural, built-in support system for the part during the build. This eliminates the need for the dedicated support structures required by other processes. This allows for the creation of incredibly complex geometries, including interlocking parts and internal channels, that would be impossible to manufacture otherwise. Both SLS and MJF are advanced PBF options compared to other 3D printing processes, which are detailed in our broader SLA vs SLS vs MJF guide.

A Deep Dive into SLS (Selective Laser Sintering)

Selective Laser Sintering is the original and most established powder bed fusion technology. It has been a trusted workhorse in rapid prototyping and manufacturing for decades, renowned for its reliability and the excellent mechanical properties of its parts.

How Does SLS Work? A Technical Look

The SLS process is a precise, point-by-point fusion method that takes place inside a heated build chamber.

- The build chamber is filled with a thermoplastic powder, typically Nylon. It is heated to a temperature just below the material's melting point. This reduces the energy needed from the laser and prevents warping.

- A recoater blade or roller spreads an extremely thin layer of this pre-heated powder (around 0.1 mm) over the build platform.

- A powerful, high-precision CO₂ laser, guided by a system of scanning mirrors called galvanometers, traces the cross-section of the 3D model onto the powder bed.

- The laser's focused energy heats the powder particles to their melting point, causing them to sinter, or fuse, together into a solid layer.

The platform then lowers, a new layer of powder is applied, and the laser sinters the next cross-section, fusing it to the layer below. This continues for thousands of layers until the parts are complete, fully encased in the block of unsintered powder.

The "Point-Based" Sintering Method

It is critical to understand that the SLS laser acts like a pencil. It must physically trace every line and fill every area of the part's cross-section. The speed of the process is therefore directly tied to how much area the laser needs to cover on each layer.

Materials and Properties

SLS offers the widest range of materials within the PBF family.

- Nylon 12 (PA12): The industry standard. It offers an excellent balance of strength, stiffness, and durability. Parts are typically white or off-white.

- Nylon 11 (PA11): More flexible and impact-resistant than PA12.

- Composite Nylons: These are PA12 powders filled with other materials to enhance properties. Examples include Glass-Filled Nylon for increased stiffness and heat resistance, and Carbon-Filled Nylon (Carbonmide) for exceptional strength and light weight.

Key Characteristics of SLS Parts

SLS parts are known for their superb, engineering-grade mechanical properties. They are strong and durable, making them suitable for rigorous functional testing and end-use applications. They have a characteristic grainy, porous surface finish, similar to a sugar cube. The standard color is a natural white, which can be easily dyed to a variety of colors in post-processing.

A Deep Dive into MJF (Multi Jet Fusion)

Multi Jet Fusion is a newer powder bed fusion technology, introduced and patented by HP. It was designed from the ground up for production speed and efficiency, offering a unique approach to fusing the powder.

How Does MJF Work? A Technical Look

Like SLS, the MJF process takes place in a heated build chamber. However, it does not use a laser.

- A recoater blade spreads a thin layer of powder across the build platform.

- A carriage containing an inkjet printing array (similar to a 2D office printer) passes over the build area. This array has thousands of tiny nozzles.

- The inkjet nozzles selectively deposit two different liquid agents onto the powder bed:

- Fusing Agent: A black, heat-absorbent ink is precisely printed onto the areas of the powder that need to become the solid part.

- Detailing Agent: An inhibiting agent is printed around the edges of the part. This agent helps to absorb excess thermal energy, preventing melt bleed and creating sharper, more defined boundaries.

- After the agents are applied, a high-power infrared lamp passes over the entire surface of the powder bed.

- The black fusing agent absorbs the infrared energy at a much higher rate than the surrounding powder. This rapidly heats the underlying powder to its melting point, fusing the particles into a solid layer.

The build platform then lowers, a new layer of powder is applied, and the process repeats.

The "Layer-Based" Fusion Method

The critical difference in MJF is that it fuses an entire layer at once. The infrared lamp exposes the whole build area simultaneously. The speed of the process is therefore independent of how many parts are on a layer; it is only dependent on the height of the build. This is the key to MJF's significant speed advantage in volume production.

Materials and Properties

MJF material selection is currently more focused than SLS.

- Nylon 12 (PA12): This is the primary material for MJF. It produces parts with excellent strength and a slightly more flexible feel than SLS PA12.

- Nylon 11 (PA11): A more ductile and flexible option.

- TPU (Thermoplastic Polyurethane): MJF can also produce parts from flexible, rubber-like TPU, which is ideal for seals, gaskets, and prototypes of elastomeric components.

Key Characteristics of MJF Parts

MJF parts have exceptional mechanical properties. Because the material is fully melted rather than just sintered, MJF parts tend to be less porous and have more isotropic properties. This means their strength is more consistent in all directions (X, Y, and Z). The surface finish is generally slightly smoother and finer than SLS. Due to the black fusing agent, all standard MJF parts have a consistent charcoal grey color.

The In-Depth Comparison: SLS vs. MJF Head-to-Head

While both technologies produce excellent functional nylon parts, the subtle differences in their processes lead to distinct outcomes in performance, aesthetics, speed, and cost.

Mechanical Properties and Part Performance

Both SLS and MJF produce parts that are far stronger and more durable than those made with entry-level processes like FDM. However, there is a key difference in isotropy. Because the laser in an SLS machine sinters the powder from above, the bond between the layers (the Z-axis) can sometimes be slightly weaker than the strength within a single layer (the X-Y plane).

MJF's thermal process, which fuses the entire layer and allows heat to penetrate downwards, generally produces parts that are more isotropic. This means their mechanical properties are nearly identical in the X, Y, and Z directions. For parts that will be subjected to complex, multi-directional loads, this uniform strength can be a significant advantage.

Resolution, Accuracy, and Feature Detail

Both technologies can produce parts with high accuracy and resolve fine details. However, MJF often has a slight edge. The use of the detailing agent at the part's boundary allows MJF to create sharper edges and finer textures. The layer-based fusion process can also result in slightly more consistent and predictable dimensional accuracy across a full build.

Surface Finish and Aesthetics

The raw, out-of-the-printer finish is a noticeable difference.

- SLS parts have a distinctly grainy, porous texture, similar to a sugar cube. The standard color is a natural white, which makes them excellent candidates for dyeing to any custom color.

- MJF parts have a slightly smoother, finer-grained texture. They feel less porous than SLS parts. Due to the carbon-based fusing agent, all standard PA12 parts are a consistent charcoal grey. While they can be dyed black for a deeper finish, they cannot be dyed to lighter colors.

Production Speed and Turnaround Time

This is where MJF has its most significant advantage.

- For a single, tall part, the speed of SLS and MJF can be comparable.

- For a build platform packed with many nested parts, MJF is dramatically faster. The MJF printer takes the same amount of time to fuse a layer whether there is one part or one hundred parts on it. The SLS printer's laser must physically travel to and trace every single one of those parts. For production runs, this means MJF can often produce parts in half the time of an SLS machine.

Material Options and Color

SLS is the clear winner in terms of material variety. The availability of composite materials like Glass-Filled and Carbon-Filled Nylon allows for the creation of parts with significantly higher stiffness and strength. For applications that require these enhanced properties, SLS is the only option between the two. Furthermore, the white base color of SLS parts provides a full spectrum of custom dyeing possibilities.

Cost per Part

The cost per part is a complex calculation based on several factors.

- Machine Cost: The initial investment in the machines is comparable.

- Speed: MJF's speed advantage in production runs allows its machine time to be amortized over more parts, often leading to a lower per-part cost.

- Powder Recyclability: Both processes allow for the recycling of the unsintered powder from a build. However, MJF typically allows for a higher "refresh rate," meaning a greater percentage of recycled powder can be used in the next build. This reduces material waste and can lower long-term costs.

For one-off prototypes, the cost is often similar. For production runs of dozens or hundreds of parts, MJF is frequently the more economical choice.

SLS vs. MJF: Pros and Cons Table

| SLS (Selective Laser Sintering) | MJF (Multi Jet Fusion) | |

| Pros | ✓ Wide range of materials (Nylon, composites) <br> ✓ White base color allows for full-color dyeing <br> ✓ Mature and highly reliable technology <br> ✓ Excellent for very large, single parts | ✓ Extremely fast for production volumes <br> ✓ More isotropic mechanical properties <br> ✓ Slightly better fine-feature resolution <br> ✓ Often lower cost-per-part at scale |

| Cons | ✗ Slower for high-volume production <br> ✗ Slightly rougher surface finish <br> ✗ Less isotropic properties than MJF | ✗ Limited material selection (primarily Nylon) <br> ✗ Parts are always a dark grey/black color <br> ✗ Less ideal for very large, bulky single parts |

Making the Right Choice for Your Application

The decision between SLS and MJF depends on prioritizing the specific needs of your project.

When Should You Choose SLS?

Choose the versatile veteran, SLS, when:

- You need a specific material property not available in MJF, such as the high stiffness of Glass-Filled Nylon or the strength of Carbonmide.

- Your part must be a specific color, especially a light or vibrant one, as the white base material is perfect for custom dyeing.

- You are producing a very large, single part that may be more economically produced with the laser-based system.

- A slightly rougher, porous surface is acceptable or even desired for applications like adhesive bonding.

When Should You Choose MJF?

Choose the high-speed specialist, MJF, when:

- Speed and turnaround time are your top priority, especially for a production run of 10 or more parts.

- The best possible isotropic mechanical properties are required for a part that will experience multi-directional stress.

- You need the finest possible feature detail and sharpest edges that a powder-based process can offer.

- The natural charcoal grey or a dyed-black finish is acceptable or desired for your final product.

- Cost-per-part at volume is a critical deciding factor.

For projects with even higher volumes, it is also worth comparing these advanced additive methods to more traditional manufacturing processes. The trade-offs between them and options like Vacuum Casting vs Injection Molding can be significant at scale.

Conclusion

The debate between SLS and MJF is a discussion between two exceptional technologies. Both are industry leaders for producing strong, functional, and complex nylon parts. There is no single "best" choice, only the most appropriate choice for a given application.

SLS is the versatile and established workhorse, offering a wide range of materials and a full color palette for customization. MJF is the high-speed production powerhouse, delivering parts with superior isotropy and a finer finish at a speed and cost-per-part that is often unmatched at scale.

By understanding the subtle but critical differences in their fusion methods, material options, and performance characteristics, you can make a truly informed decision. As a manufacturing partner with deep expertise in both technologies, GD-Prototyping can provide unbiased advice to ensure you select the perfect process to bring your design to life.