A Guide to Silicone Mold Life in Vacuum Casting

The magic of vacuum casting lies in its unique tooling: the soft silicone mold. This flexible, high-precision tool is what allows for the rapid and cost-effective production of high-quality plastic parts. It can capture every microscopic detail of a master pattern. It can also create complex parts with undercuts that would be impossible with a rigid metal mold. However, this remarkable tool has a finite lifespan. Unlike a hardened steel injection mold, a silicone mold is a consumable item. Understanding its realistic lifespan is crucial for project planning, costing, and managing quality expectations.

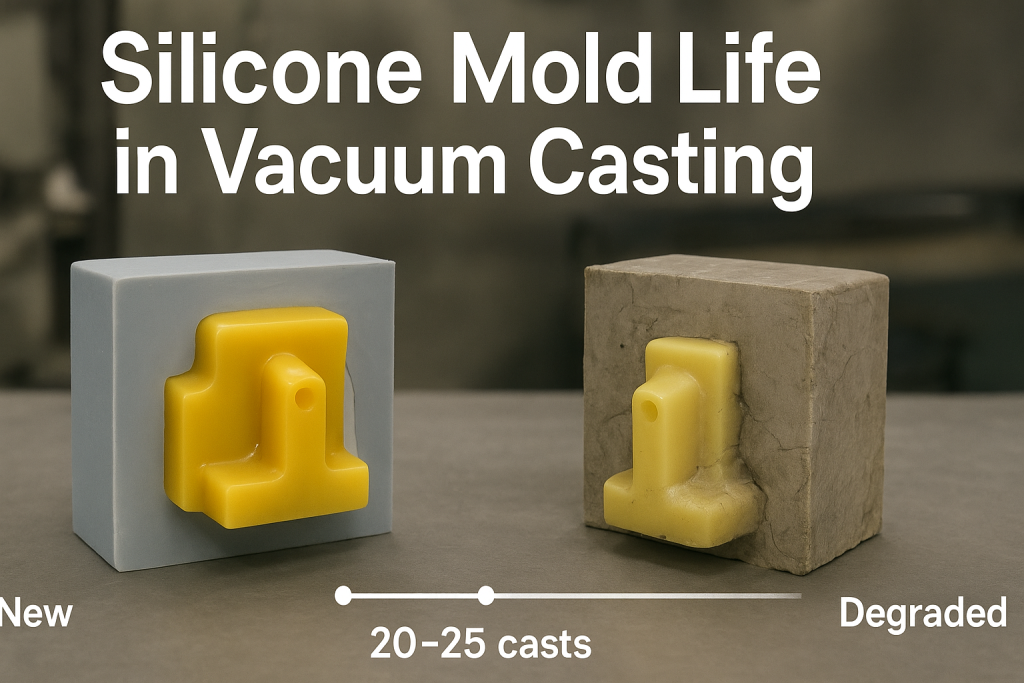

The typical life of a silicone mold in vacuum casting is between 20 to 25 parts. However, this is not a fixed number. It is a general industry average. The actual lifespan of a specific mold can vary significantly. It can range from as few as 10 to as many as 30 or more parts. This variation is not random. It is the predictable result of several critical factors, including part design, material choice, and process control.

As a leader in the craft of vacuum casting, GD-Prototyping has deep, hands-on experience in making and using thousands of silicone molds. We understand the science of what makes them durable and what causes them to fail. This guide provides a comprehensive exploration of silicone mold life. We will detail the mechanisms of degradation, analyze the factors that influence longevity, and offer best practices to maximize the output of each tool.

The Science of Mold Degradation: Why Does a Silicone Mold Wear Out?

A silicone mold does not last forever because it is subjected to a repeated cycle of intense chemical, thermal, and mechanical stresses. Each part that is cast contributes a small, cumulative amount of damage to the mold. Over time, this damage builds up, and the mold eventually reaches the end of its useful life. To understand how to extend this life, we must first understand the three primary mechanisms of degradation.

Chemical Attack

The process of casting a part involves a chemical reaction. Two-part liquid polyurethane resins are mixed, and they cure into a solid plastic inside the mold. This curing process can be chemically aggressive. Some of the chemical components in the resin, as well as the heat generated by the reaction, can slowly attack the silicone rubber. Over many cycles, these chemicals can begin to leach essential plasticizers and oils from the silicone. This causes the mold to become progressively more brittle, less flexible, and more prone to tearing.

Thermal Cycling

The curing of polyurethane resins is an exothermic reaction, meaning it generates its own heat. The temperature inside the mold can rise significantly during this phase. After the part is removed, the mold cools back down to room temperature before the next part is cast. This repeated cycle of heating and cooling causes the silicone material to constantly expand and contract. This thermal cycling induces microscopic stress and fatigue within the polymer structure of the mold. Over time, this fatigue can lead to a loss of elasticity and the formation of small surface cracks.

Mechanical Stress

This is often the most significant factor in mold degradation. A silicone mold is flexible, but it is not indestructible. To remove a cured plastic part, the mold must be physically pulled apart, bent, and stretched. This is especially true for parts with complex geometries or deep undercuts. Each time the mold is flexed to release a part, it puts mechanical stress on the silicone. This can cause microscopic tears, particularly at sharp internal corners or on thin, delicate features within the mold cavity. With each subsequent part, these small tears can grow larger, eventually leading to a complete failure of the mold.

The Critical Factors Influencing Silicone Mold Life

The exact number of parts a single silicone mold can produce is not a matter of chance. It is a predictable outcome based on a combination of factors related to the part's design, the material being cast, and the skill of the technician. A clear understanding of these variables is key to accurately estimating the tooling requirements for any vacuum casting project.

Part Geometry and Complexity

The shape of the part being cast is arguably the single most important factor determining mold life.

- Undercuts and Deep Features: A part with deep, complex undercuts requires the mold to be stretched and flexed significantly during demolding. This high level of mechanical stress is the primary cause of tearing and is the most common reason for a short mold life. A simple, open-faced part with no undercuts will put very little stress on the mold, leading to a much longer lifespan.

- Thin Walls: If the part design includes very thin, delicate walls or features, the corresponding sections of the silicone mold will also be very thin and delicate. These sections are fragile and can easily tear or break off during the repeated stress of demolding.

- Sharp Internal Corners: Sharp corners on a part create sharp corners in the mold cavity. These corners act as stress risers. They create a natural weak point where a tear is likely to start. Designs that incorporate generous radii on all internal corners will result in a much more durable mold.

The Chosen Casting Resin

The specific polyurethane resin used to cast the parts has a direct impact on the mold's longevity.

- Resin Aggressiveness: Some polyurethane formulations are more chemically aggressive than others. Resins with a higher concentration of certain catalysts or additives can accelerate the chemical degradation of the silicone, making it brittle more quickly.

- Curing Temperature (Exotherm): Different resins generate different amounts of heat as they cure. A resin with a high exotherm will subject the mold to greater thermal cycling stress. This can shorten its life compared to a low-exotherm resin.

- Material Hardness: The hardness of the final cast part also plays a role. Casting a very soft, flexible rubber-like part (e.g., Shore 40A) puts relatively little stress on the mold during demolding. Casting a very hard, rigid plastic (e.g., Shore 85D) requires more force to remove from the mold, which increases the mechanical stress on the silicone.

The Master Pattern's Surface Finish

The texture of the part's surface can have a surprising effect on mold life.

- Highly Polished Surfaces: A master pattern that is polished to a smooth, glossy finish (SPI-A1) will create a very smooth mold cavity. A smooth surface has a low coefficient of friction, which makes the parts easier to release. This lower demolding force results in less stress and a longer mold life.

- Heavily Textured Surfaces: A master pattern with a complex, grained texture (like a simulated leather or wood grain) will create a mold cavity with thousands of microscopic undercuts. The cast part will lock into these tiny features. This dramatically increases the force required to demold the part, placing much higher mechanical stress on the mold and typically leading to a shorter lifespan.

The Skill of the Technician

Urethane casting is a craft that relies on the skill of the technician.

- Mold Cutting Technique: The way the parting line is cut into the cured silicone block is crucial. A skilled technician will cut the mold in a way that minimizes stress risers and creates a robust tool. A poorly planned cut can create thin, weak sections that are destined to fail early.

- Demolding Technique: There is a significant amount of skill involved in removing a part from the mold. An experienced technician knows exactly how to flex and bend the mold to release the part with the minimum possible stress. A rough or careless demolding technique will quickly destroy even a well-made mold.

Silicone Mold Life: Ranges and Factors Table

This table provides a quick reference to the key factors that influence mold life and their relative impact. Use this guide to understand why the lifespan for your specific project might be shorter or longer than the 20-25 part average.

| Factor | Impact on Mold Life | Best Case Scenario (Long Life) | Worst Case Scenario (Short Life) |

| Part Geometry | High | Simple, open shape. No undercuts. Generous radii. | Complex shape with deep undercuts and thin walls. |

| Casting Resin Type | Moderate | Soft, flexible resin (low Shore A). Low exotherm. | Hard, rigid resin (high Shore D). High exotherm. |

| Surface Finish | Moderate | Highly polished, glossy finish (SPI-A1). | Deep, complex matte texture (e.g., leather grain). |

| Technician Skill | High | Expert mold cutting and careful, patient demolding. | Rushed or improper demolding technique. |

How to Maximize the Life of Your Silicone Mold

While mold wear is inevitable, there are several best practices that can be followed to maximize the number of high-quality parts produced from a single mold.

Best Practices for Extending Mold Longevity

Design parts with generous draft and radii. While vacuum casting allows for zero-draft features, incorporating a small amount of draft and rounding sharp corners will always reduce the stress during demolding and extend the life of the mold.

Choose the least aggressive resin that meets your needs. If your project does not require extreme rigidity, consider using a slightly softer polyurethane. This will make the parts easier to remove from the mold.

Apply a high-quality mold release agent. A thin, even coat of a silicone-safe mold release agent should be applied to the mold cavity before each and every cast. This creates a barrier that prevents the resin from sticking and reduces friction during demolding.

Allow the mold to cool completely between cycles. Casting parts back-to-back without allowing the mold to return to ambient temperature can cause a buildup of thermal stress. Allowing the mold to rest and cool will increase its overall lifespan.

Handle the mold with care during demolding. The technician should use the minimum force necessary to release the part. The mold should be flexed gently and evenly, avoiding any sharp, tearing motions.

Store the mold properly when not in use. When a mold is not being used, it should be cleaned and stored in a cool, dark place. Exposure to UV light and high temperatures can degrade the silicone over time.

The Impact of Mold Wear on Part Quality

As a silicone mold nears the end of its life, the degradation will begin to show on the surface of the cast parts. It is the responsibility of a quality-focused service provider to monitor the parts and decide when a mold is no longer capable of producing acceptable results.

How Does a Degrading Mold Affect the Parts?

1. Loss of Fine Detail

One of the first signs of mold wear is the softening of fine details. Sharp edges in the mold cavity will become slightly rounded. Small, crisp text will become less defined. Intricate textures will start to lose their sharpness.

2. Degradation of Surface Finish

The surface finish of the parts will also change. A mold that was created from a highly polished master pattern will initially produce glossy parts. As the mold wears, the parts will become progressively more dull and matte in appearance.

3. Impact on Tolerances

As the mold is repeatedly stretched and flexed, it can begin to deform slightly. This means that the dimensional accuracy of the parts can start to drift. A part cast late in the mold's life may have slightly different dimensions than a part cast when the mold was new. This wear is a key factor in defining the achievable Vacuum Casting Tolerances over a full production run.

It is also important to consider how the material properties of the cast parts, which are often selected from a Shore Hardness Chart, can affect the mold. A very rigid plastic will put more stress on the mold during removal than a soft, flexible one.

Conclusion

The lifespan of a silicone mold in vacuum casting is a variable, not a fixed number. While an average of 20-25 parts is a good baseline, the actual output is a direct result of the interplay between part design, material choice, and process execution. A complex part with a heavy texture being cast from a rigid plastic will result in a short mold life. A simple part with a polished finish being cast from a soft rubber will result in a much longer mold life.

Understanding these factors is key to planning a successful low-volume production run. It allows for accurate quoting and ensures that part quality remains consistent from the first unit to the last. At GD-Prototyping, our deep experience in the craft of mold making allows us to optimize every project to maximize the life of our tooling, delivering the highest possible quality and value to our clients.