Sheet Metal Housing Fabrication: Bending & Welding Experts

What is Housing Fabrication Sheet Metal?

The mechanism, which includes the planning, production, and assembly of a metal casing with metal of superior-quality sheet metal, is the sheet metal housing fabrication. They are housing that are put to diverse use, e.g.:

- Protecting the electronic parts against dust, moisture, and mechanical damage.

- Maintenance of industrial machines and power stations.

- Commercial and industrial design of aesthetics and ergonomic design.

The modern sheet metal housings are more exact, stable, and resilient than ever because of the introduction of CNC sheet metal making, laser cutting, and precision assembly methods.

Sheet Metal Housing GD Prototyping

A sheet metal housing production is one of the critical services of GD Prototyping, in which the quality, reliability, and precision of the product are coupled with the finest production methods. Sheet metal is a flexible industry material that is manufactured in thin sheets in a thin and flat form. It comes either in flat sheets or in coiled strips and is easily cut, bent, and can be any shape, hence its application in enclosures, cabinets, and any shape that is required by industry.

- We are GD Prototyping, an organization that is involved in the manufacture of quality sheet metal housings and other related components. We have numerous applications where we are specialized, like sheet metal chassis, cabinets, equipment shells, advertising machine shells, and stainless steel products. Other products that we manufacture are shell monitoring system equipment, automation equipment, medical device cabinets, outdoor cabinets, power outdoor cabinets, highway peripheral equipment shells, and other custom sheet metal products.

- So we have acquired high production capacities of CNC stamping, precision cutting, bending, and welding, such that all our products are of high quality. You may have in prototype form, a small batch, or large-scale industrial manufacturing of custom sheet metal housings that are strong, durable, and attractive, which are built by us.

- GD Prototyping ensures, through experience, that every sheet metal housing is designed for optimal performance. We have heard how important and permanent in the industrial and electronic service to be accurate and enduring. Our group works with customers in designing, output, and production of housings based on the requirements.

The Housing Fabrication Process Sheet Metal

Fabrication is manufactured in numerous steps, and the process is fundamental to the quality and functionality of the finished product.

Design and Engineering

Any project starts with a sheet metal enclosure design and fabrication plan. Engineers consider:

- Material type and thickness

- Flexing permissibles and tolerances.

- Environmental and mechanical specifications.

Aesthetic Design Elements

The existing CAD programs allow creating a housing that meets the technical and operational requirements because they are modelled strictly.

Material Selection

The performance is determined by the choice of material of choice. Common materials include:

Aluminum: This material is not corrosive, and it is light; it should be applied to electronic enclosures.

Stainless Steel: Tough, non-wearing, and can be applied both in the industry and outdoors.

Galvanized Steel: Low-end corrosion-free steel applied in general industries.

The immediate impact of the material used is on the service life, mass, and defensive ability.

Cutting and Shaping

High-accuracy Manufacturers cut and shape metal sheets with high accuracy by cutting and stamping metal sheets using laser-cut metal housings, sheet metal stamping, or CNC sheet metal fabrication. Techniques include:

- Laser cutting

- Punching

- Bending and forming

- Stamping

The current state-of-the-art CNC machines ensure accuracy, reduce waste, and cut down the production timelines.

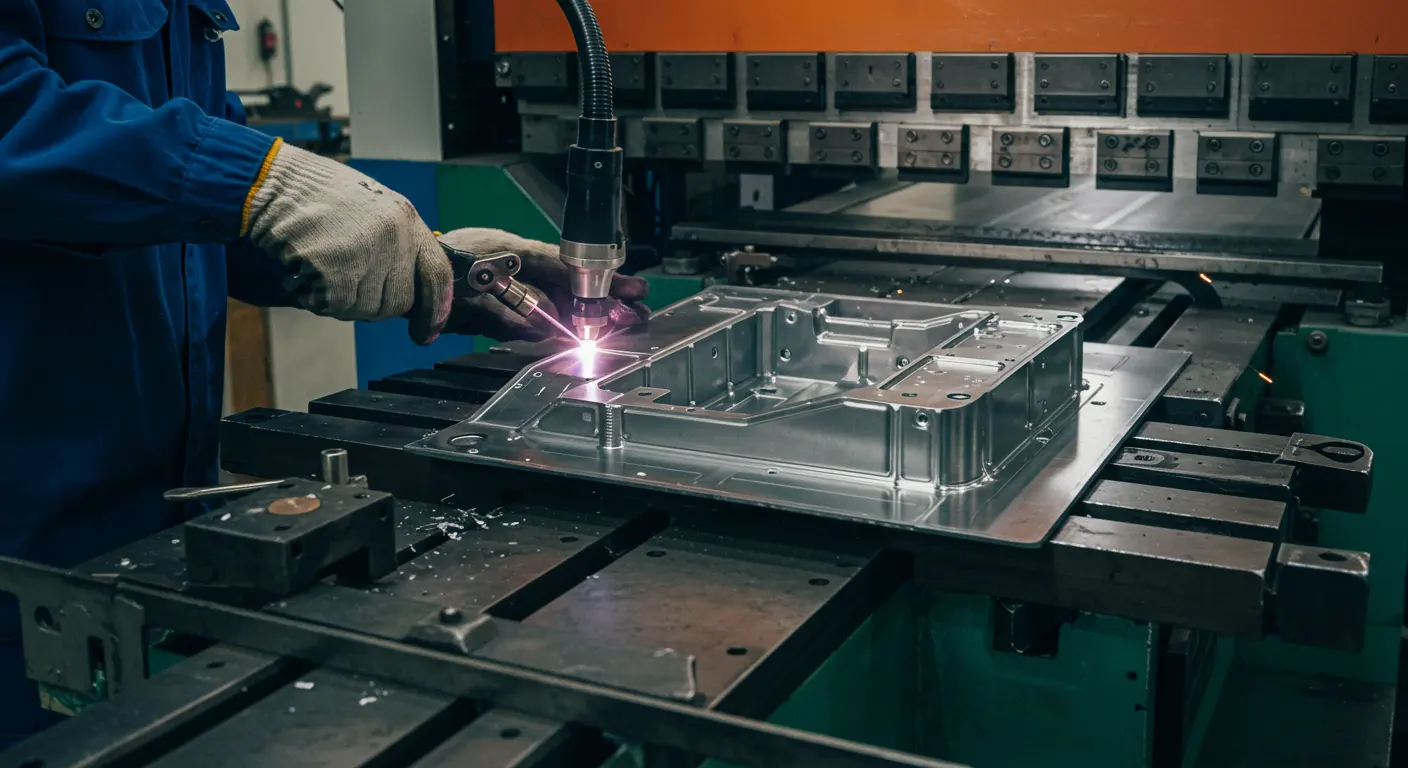

Joining and Assembly

Once these elements have become sufficiently fluent, they are put together with:

- Welding (TIG, MIG)

- Fastening (screws, rivets)

- Adhesive bonding

- The building is structurally sound and strong because of quality assembly.

- Finishing and Treatment of Surface.

Some of the factors include corrosion, UV, and wear of the environment, and are therefore avoided by applying the right surface treatment to the enclosure.

Advantages of Sheet Metal Housing Fabrication

The benefits of utilizing the service of professional fabrication of sheet metal housing are as follows:

Precision and Accuracy

The CNC technology and precision sheet metal fabrication give rise to the fact that every housing is created to specifications, fits together perfectly, and works in a very reliable fashion.

Customization

The custom sheet metal housing and fabrication services for multi-faceted industrial housings offer the chance to develop new solutions to the unique applications.

Durability and Protection

Exceptional metal enclosures provide superior physical impact, dust, dampness, and heat shield, which enhances the life of encased equipment.

Cost-Efficiency

Small-batch production and prototyping with sheet metal is cost-effective and time-saving when developing products, and is feasible with start-ups and industrial research and development.

Sheet Metal Housing Uses

Metal enclosures may be produced in any of the following industries:

Electronics: PCB enclosures, sensor enclosures, control unit enclosures.

Telecommunication Server Rack: Telecom equipment housing, and telecom cabinets.

Mechanical Buildings: Control boards, machine casings, and electrical casings.

Medical Devices: Enclosure of diagnostic and monitoring implants.

Consumer Products: Steel enclosures that are long-lasting and used in appliances and other devices.

This is seen in such applications where the assembly of housings using sheet metal is done to ensure functionality, safety, and beauty.

Making the Correct Choice of Fabrication Ally

The cooperation with a respected manufacturer will ensure quality, consistency, and timely delivery. Among the key factors that need to be put into consideration are:

- Skill in the construction of metal houses in industries.

- Ability to handle prototype and small-scale production.

- Metal housing cut by high-tech CNC and laser.

- Powder-coated finishes and custom finishes experience.

Design and Engineering Support

You can look at GD Prototypes, where you will find more professional assistance to manufacture sheet metal housing.

New Technology of Fabrication Sheet Metal Housing

Advanced CNC and Automation

CNC automation to fabricate housing sheet metal is maximizing the speed, precision, and reduction of errors and waste materials in housing fabrication.

Lightweight and Durable Materials

The lower weight in the form of aluminum alloy and high-level coating is increasingly becoming popular so as to maintain longevity and corrosion resistance.

Merger with Electronics

Intelligent housings have incorporated pre-holes, cable management solutions, and enhanced heat dissipation design to fit in electronics.

Sustainable Practices

The recycling of scrap metal, the usage of environmentally friendly coating, and optimization of the production process make modern fabrication greener and cost-effective.

Conclusion

The art of the sheet metal housing manufacture is not merely about bending metal sheets and welding them, but conjures up sustainable, precise, and custom-made answers to numerous modern-day industrial and electronic demands. Professional fabrication services are very good and provide accurate completion of your work, whether you are interested in a custom sheet metal housing, industrial enclosures, or prototype metal housings. One needs to go to GD Prototyping to find an array of sheet metal housing fabrication services that allow him to have a solution that he can trust, a solution that will meet his needs.