Rapid Tooling vs Production Tooling: A Complete Guide

In the world of injection molding, the most critical, complex, and costly component is the tool itself. The mold is the heart of the entire process. Its quality dictates the quality of every part produced. For any company developing a plastic part, the choice of tooling is a major strategic decision. It directly impacts project timelines, budget, and the scalability of manufacturing. The two primary paths a project can take are rapid tooling and production tooling. While both create injection molds, they are designed for vastly different purposes.

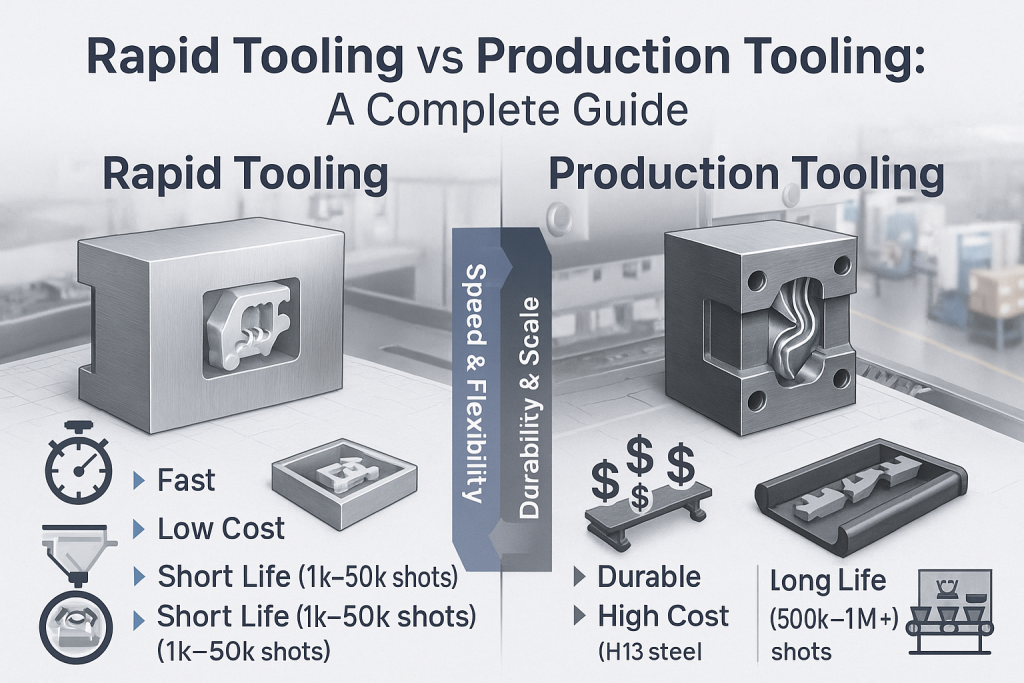

The main difference is that Rapid Tooling uses softer materials like aluminum or P20 steel to create molds quickly and affordably for prototyping and low-volume runs, while Production Tooling uses hardened steels like H13 to create highly durable molds designed for mass production and millions of cycles. Understanding the specific advantages and limitations of each approach is essential for making a sound business and engineering decision.

As an expert in both rapid and production toolmaking, GD-Prototyping has guided countless clients through this critical choice. This guide provides a deep, technical comparison of the two tooling philosophies. It will equip you with the knowledge to select the right tooling strategy for any stage of your product's lifecycle.

Understanding Rapid Tooling: Speed for Prototyping and Bridge Production

Rapid tooling, also known as prototype tooling or soft tooling, is a process focused on one primary goal: speed. Its purpose is to create a functional injection mold in the shortest possible time. This allows product development teams to get real, molded parts in their hands quickly for testing and validation. It bridges the crucial gap between initial prototypes (like 3D prints) and full-scale production.

What is Rapid Tooling?

Rapid tooling is the manufacturing of injection molds using materials and methods that prioritize speed and lower cost over extreme longevity. Instead of taking months to build, a rapid tool can often be produced in just a few weeks. This acceleration is achieved by using softer, more easily machinable materials and often simplifying some of the more time-consuming aspects of traditional toolmaking.

Common Materials for Rapid Tools

The choice of material is the key differentiator for rapid tooling.

- Aluminum 7075: This is a popular choice for rapid tooling. Aluminum is significantly easier and faster to CNC machine than steel. It also possesses excellent thermal conductivity. This allows it to heat up and cool down quickly, which can lead to shorter cycle times. While it is a "soft" tool material, it is still a strong alloy capable of producing thousands of high-quality parts.

- P20 Steel: P20 is a versatile, pre-hardened tool steel. It is not as hard as the steels used for production tooling, which makes it easier to machine. However, it is significantly more durable and wear-resistant than aluminum. A P20 mold is a great intermediate option. It can produce tens of thousands of parts, making it ideal for low-volume production or extensive market testing.

Key Characteristics of Rapid Tooling

The nature of rapid tooling is defined by a set of distinct characteristics:

- Speed: The lead time for a rapid tool is dramatically shorter, typically ranging from 2 to 6 weeks. This is a fraction of the time required for a production tool.

- Lower Cost: The combination of more affordable materials and reduced machining time makes rapid tooling significantly less expensive. This lowers the barrier to entry for creating real injection molded prototypes.

- Limited Lifespan: A rapid tool is not designed to last forever. An aluminum tool might produce 1,000 to 10,000 parts. A P20 tool might produce up to 50,000 parts. This is far less than the million-shot lifespan of a production tool.

- Design Flexibility: Because the materials are softer, it is much easier and faster to modify a rapid tool. If testing reveals a design flaw, the tool can be quickly updated to produce a new iteration of the prototype.

When is Rapid Tooling the Right Choice?

Rapid tooling is the ideal solution at several key stages of product development:

- Functional Prototyping: When you need to test a design with the actual production material.

- Market Testing: To produce a small batch of products for a pilot launch or to gather customer feedback.

- Bridge Production: To serve as a "bridge" to get a product to market quickly while a long-lead-time production tool is still being built.

Understanding Production Tooling: Durability for Mass Production

Production tooling, also known as hard tooling, is designed with one primary goal: longevity. It is a significant capital investment built to withstand the rigors of high-volume, continuous manufacturing. A single production tool is expected to produce hundreds of thousands, or even millions, of identical parts over its lifetime.

What is Production Tooling?

Production tooling is the manufacturing of ultra-durable, high-precision injection molds using hardened tool steels. Every aspect of its design and construction is optimized for repeatability, reliability, and an extremely long operational life. These are the tools that are used in factories to mass-produce the plastic products we use every day.

Common Materials for Production Tools

The materials used for production tooling are chosen for their extreme hardness, wear resistance, and ability to hold a fine polish.

- H13 Tool Steel: This is a workhorse material for production molds. It is a chromium-molybdenum hot-work steel with excellent toughness and resistance to thermal fatigue. It is typically heat-treated to a high hardness (around 48-52 HRC) after machining.

- S136 Stainless Steel: This is a high-grade stainless tool steel. It can be polished to an extremely high, mirror-like finish (SPI-A1). It is also highly corrosion-resistant. This makes it the ideal choice for molding optical parts like lenses or for use with corrosive plastics like PVC.

Key Characteristics of Production Tooling

Production tools are built to a much higher and more robust standard.

- Extreme Durability: A well-maintained production tool made from H13 steel is often guaranteed for a lifespan of one million shots or more.

- High Upfront Cost: These tools are a significant capital investment. The cost reflects the expensive materials, complex manufacturing processes, and extensive skilled labor required to build them.

- Long Lead Time: The lead time for a production tool is substantial, often ranging from 8 to 16 weeks or more.

- Complex Design: Production tools often incorporate sophisticated features. These can include advanced cooling channels for faster cycle times, complex side-actions for undercuts, and hot runner systems to reduce material waste.

When is Production Tooling the Right Choice?

Production tooling is the only choice for:

- Mass Production: When a product has a finalized, validated design and is ready for high-volume manufacturing (typically 100,000 units or more).

- Long-Term Projects: For products that will be manufactured for many years.

- Abrasive Materials: When molding plastics that are filled with abrasive materials like glass or carbon fiber, which would quickly wear out a softer tool.

The Durability vs. Lead-Time Chart: A Visual Guide

This chart provides a simple, at-a-glance comparison of the core trade-offs between the different tooling options.

| Tooling Type | Tool Material | Typical Lead Time | Expected Tool Life (Shots) | Relative Cost |

| Rapid Tooling | Aluminum 7075 | 2 - 4 Weeks | 1,000 - 10,000 | $ |

| Rapid Tooling | P20 Steel | 3 - 6 Weeks | 10,000 - 50,000 | $$ |

| Production Tooling | H13 Hardened Steel | 8 - 16+ Weeks | 500,000 - 1,000,000+ | $$$$$ |

A Deep Dive into Key Differences

Beyond the headline numbers, several critical technical and financial differences separate rapid and production tooling.

Tool Material and Hardness

The material is the core differentiator. Hardened H13 steel is vastly superior to aluminum or P20 steel in terms of wear resistance. This is especially important when using abrasive, glass-filled plastics. A glass-filled nylon would quickly erode the fine details in an aluminum mold. It would have very little effect on a hardened H13 tool, even after hundreds of thousands of shots. This hardness also allows the production tool to withstand the immense clamping pressures of a high-speed injection molding press for millions of cycles without deforming.

Tool Design and Complexity

A production tool is a much more complex and optimized piece of engineering.

- Cooling Systems: Production tools feature intricate, optimized cooling channels that are designed to minimize the cycle time. Faster cooling means more parts per hour, which lowers the cost-per-part.

- Ejection Systems: They often have more complex and robust ejection systems designed for high-speed, automated operation.

- Gating and Runners: Production tools often use hot runner systems. These keep the plastic in the runner channels molten, eliminating waste and improving the process. The choice of Injection Molding Gate Types is a much more critical design decision in production tooling to ensure cosmetic quality and part performance.

Cost Analysis: Tool Cost vs. Cost-Per-Part

This is the most important financial consideration.

- Rapid Tooling has a very low initial tool cost but a slightly higher cost-per-part. This is because the cycle times may be longer, and the tool is less automated.

- Production Tooling has a very high initial tool cost but a very low cost-per-part. The tool is optimized for maximum speed and efficiency.

There is a break-even point. For low quantities, the total project cost is dominated by the tool price, making rapid tooling the cheaper option. As the quantity increases, the total cost becomes dominated by the price of each part. The lower cost-per-part of the production tool eventually overcomes its high initial price. A thorough cost analysis is essential to determine this break-even point for your project.

Lead Time and Time-to-Market

In today's fast-paced markets, speed is a competitive advantage. This is the primary driver for rapid tooling. The ability to go from a final design to real, molded parts in just a few weeks can be a game-changer. It allows a company to launch a product, generate revenue, and gain market share months before a competitor who chose to wait for a production tool.

Making the Strategic Choice: Which Tooling is Right for Your Project?

The choice between rapid and production tooling is a strategic decision that should be based on your project's specific phase and goals.

A Decision Framework for Your Product Lifecycle

Choose Rapid Tooling if:

- You are in the prototyping or validation stage and need to test a design with production-grade materials.

- You need a small batch of parts for certification, market testing, or a pilot launch.

- You need "bridge tooling" to start production and sales immediately while a long-lead-time production tool is being manufactured.

- Your product is a low-volume item that is not expected to sell more than 50,000 units over its lifetime.

For very low volumes or initial form/fit prototypes where the exact material is not required, it is also worth comparing rapid tooling to other methods. A deep dive into Vacuum Casting vs Injection Molding can reveal alternative paths for small-batch production.

Choose Production Tooling if:

- Your product design has been fully tested, finalized, and validated.

- You are entering mass production and expect to produce 100,000 units or more.

- The long-term cost-per-part is the most critical financial driver for the project's profitability.

- The part will be molded from a highly abrasive, glass-filled material that requires a hardened steel tool.

Conclusion

The decision between rapid tooling and production tooling is a critical strategic choice. There is no universally "better" option. The correct choice is the one that aligns with your project's volume, timeline, and budget. Rapid tooling offers unparalleled speed and flexibility, making it the perfect tool for the early stages of the product lifecycle. Production tooling provides unmatched durability and efficiency, making it the essential foundation for mass production.

By understanding the distinct purposes and capabilities of each, you can make an informed decision that optimizes your path to market. At GD-Prototyping, our team of experts is fluent in both tooling philosophies. We can provide the unbiased guidance and high-quality toolmaking needed to support your project at any stage, from the first prototype to the millionth part.