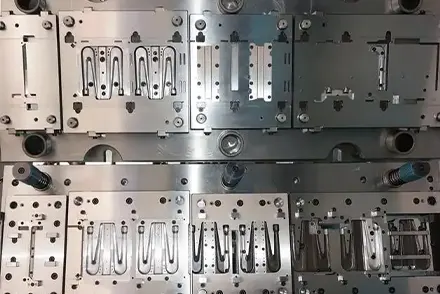

Progressive Stamping Die

Progressive stamping die processing uses stamping molds and presses to apply pressure on sheet metal or blanks, causing plastic deformation, separation, or forming to achieve the desired shape and size.

-

Progressive stamping uses molds and presses for shaping.

-

Materials include steel, aluminum, copper, and alloys.

-

Advantages: high efficiency, precision, and low cost.

-

Applied in automotive, electronics, appliances, and medical.

Progressive Stamping Die Services

Progressive stamping die is a precise metal forming process that uses a series of dies and pressure machines to shape or cut sheet materials into complex parts. It offers high efficiency, consistent quality, and excellent material utilization for various industries.

Advantages of Progressive Stamping Die

High Efficiency

Progressive stamping enables continuous, automated processing, making it ideal for mass production with reduced cycle times.

Stable Quality

Delivers consistent precision and repeatability, ensuring uniform part dimensions and reliable product performance.

Excellent Material Utilization

Optimized die design minimizes waste, maximizing material usage and reducing overall production costs.

Cost-Effective Manufacturing

Lower labor and tooling costs combined with high output make it a highly economical metal forming solution.

Progressive Stamping Die General Tolerances

For most progressive stamping die parts, general tolerances typically follow industry standards unless otherwise specified in the technical drawings. Actual tolerances depend on factors such as part complexity, material properties, die design, and press conditions.

Part lengths of up to 118" are available on our platform process dependent. Please inquire about anything larger. Tolerances listed here are minimums for an ideal case. Looser tolerances may be required depending on process, material choice, or part geometry. contact us

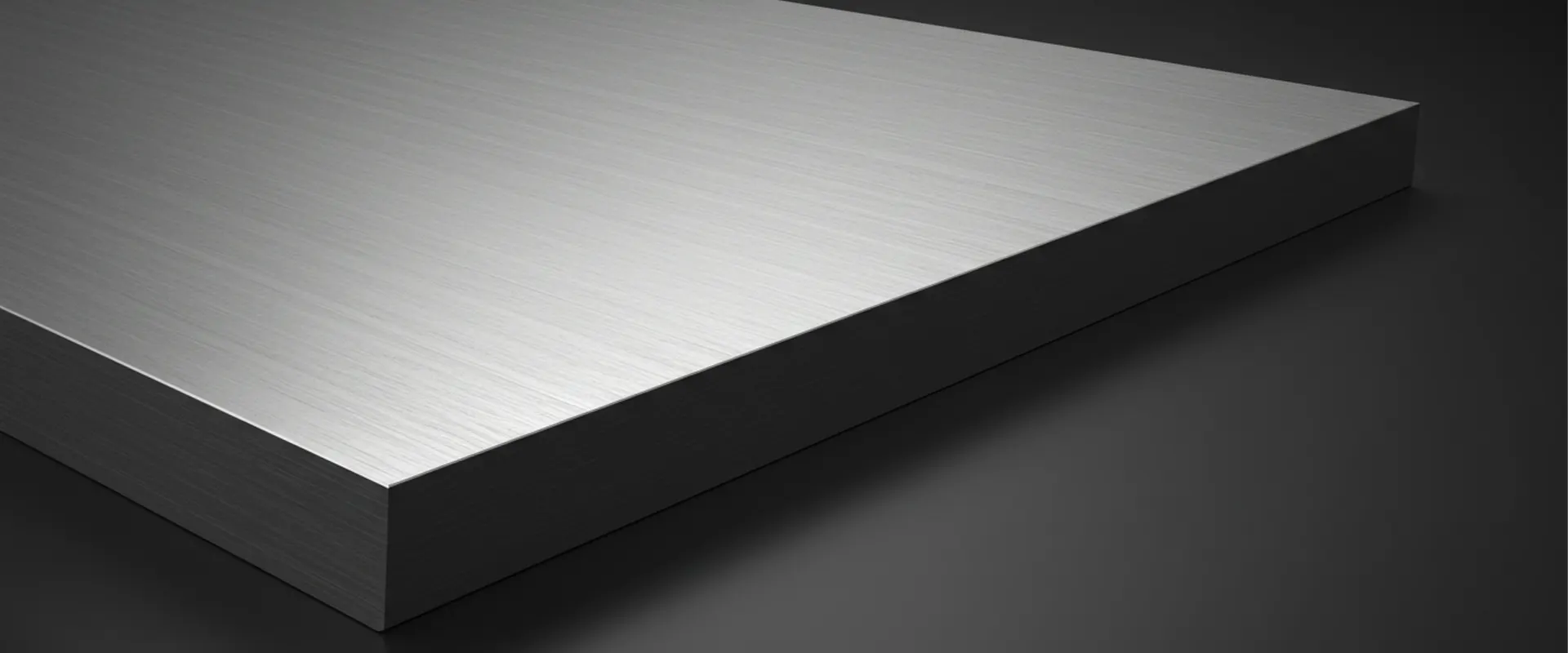

Progressive Stamping Die Materials

A variety of CNC machined metal and plastic part options are available for an instant online quote.

- Aluminum 6061

- Aluminum A5052

- ADC12

- LY12

- AL T6

- AL T51

- A1100

- Aluminum Alloy 2A12

- 2A12

- Alumina Ceramic

- Brass

- Copper(CU)

- Magnesium Alloy

- Zinc Alloy (Zn)

- Aluminum 3003

- Aluminum A5056

- A2017

- Copper Alloy C3604

- Aluminum Alloy 5000

- AL1070

- Aluminum Alloy AL2024 / A2024-T6

- Aluminum Alloys AL7075 / 7050 / 7451

- Imported Aluminum Alloy 5083

- Imported Aluminum Alloy 6082

- Imported Aluminum Alloy 7075

- Imported Aluminum Alloy 6061-T561

- AL1060

- 2A14

- C2801P-1/2H

- C1020P

- A7072

- A7000

- C1100

- A2014

- Aluminum Alloy 7000

- Titanium Alloy

- 7075

- A2011

- A2024

- A7050

- 11SMn30

- Aluminum 6061

Aluminum 6061

Aluminum 6061 is a lightweight, versatile alloy with excellent strength, corrosion resistance, and weldability. Widely used in aerospace, automotive, marine, and structural engineering.

Density:

2.8 g/cm³

- Aluminum A5052

Aluminum A5052

Aluminum A5052 is a strong, corrosion-resistant alloy with excellent weldability, ideal for marine, automotive, and industrial applications.

Density:

2.8 g/cm³

Price:

approx. $ 2.98/kg

- ADC12

ADC12

ADC12 is a widely used die-casting aluminum alloy known for good casting performance, high strength, and excellent corrosion resistance. It is commonly used in automotive parts, electronics housings, and machinery components.

Alloy:

ADC12

Casting Performance:

Excellent for die casting

- LY12

LY12

LY12 is a high-strength, heat-treatable aluminum alloy primarily composed of aluminum and copper. It offers excellent fatigue resistance and good machinability, but lower corrosion resistance. Widely used in aerospace, transportation, and structural components.

Density:

2.8 g/cm³

Fatigue Resistance:

Excellent

- AL T6

AL T6

AL T6 is a heat-treated aluminum alloy with excellent strength, corrosion resistance, and good machinability. The “T6” temper indicates it has been solution heat-treated and artificially aged to achieve peak mechanical properties. Widely used in aerospace, automotive, and structural parts.

Alloy:

AL T6

Casting Performance:

Excellent for die casting

- AL T51

AL T51

T51 is a temper designation applied to aluminum alloys that have been stress-relieved by stretching after heat treatment. Commonly seen in alloys like 6061-T51 and 7075-T51, this temper improves dimensional stability and reduces internal stress, while maintaining good strength and corrosion resistance.

Alloy:

AL T51

Casting Performance:

Excellent for die casting

- A1100

A1100

A1100 is commercially pure aluminum (99%+ purity) with excellent corrosion resistance, workability, and thermal conductivity. It is soft, ductile, and non-heat-treatable. Widely used in chemical equipment, roofing, cooking utensils, and decorative parts.

- Aluminum Alloy 2A12

Aluminum Alloy 2A12

2A12 is a high-strength aluminum-copper alloy commonly used in aerospace and high-load structural applications. It offers excellent fatigue resistance and good machining performance but has relatively low corrosion resistance, so surface treatment is often required.

- 2A12

2A12

2A12 is a high-strength, heat-treatable aluminum-copper alloy, widely used in aerospace, transportation, and structural components. It is known for its excellent fatigue resistance and good machinability. However, its corrosion resistance is lower compared to non-copper alloys, so surface protection is usually required.

- Alumina Ceramic

Alumina Ceramic

Alumina ceramic with >90% Al₂O₃ content is a high-hardness, high-temperature ceramic material used for wear resistance, electrical insulation, and cutting tools.

- Brass

Brass

Brass is a copper-zinc alloy known for its good mechanical properties, excellent corrosion resistance, and attractive golden color. It is widely used in decorative fittings, electrical components, plumbing, and precision machined parts.

Density:

8.9 g/cm³

- Copper (CU)

Copper (CU)

Copper is a versatile metal with excellent conductivity, corrosion resistance, and durability, widely used in electrical, industrial, and structural applications.

Color:

Brass/Bronze/Copper

Density:

8.9 g/cm³

- Magnesium Alloy

Magnesium Alloy

Magnesium alloy is a lightweight metal alloy known for its high strength-to-weight ratio, excellent machinability, and good vibration damping. It is widely used in aerospace, automotive, and electronics industries where weight reduction is critical.

Density:

1.9 g/cm³

- Zinc Alloy (Zn)

Zinc Alloy (Zn)

Zinc alloy is a versatile metal alloy known for its good strength, excellent castability, and corrosion resistance. It is widely used in die casting for automotive parts, hardware fittings, and decorative items.

Density:

6.8 g/cm³

- Aluminum 3003

Aluminum 3003

Aluminum 3003 is a commercially pure aluminum alloy with manganese as the primary alloying element. It offers good corrosion resistance, excellent workability, and moderate strength. It is commonly used in roofing, siding, and cookware applications.

- Aluminum A5056

Aluminum A5056

Aluminum A5056 is a strong, corrosion-resistant alloy with excellent weldability, widely used in marine, automotive, and industrial applications.

Density:

2.8 g/cm³

- A2017

A2017

A2017 is a high-strength aluminum-copper alloy known for excellent machinability and good mechanical properties. It is commonly used in aerospace, transportation, and precision machinery. Corrosion resistance is moderate, often requiring surface treatment.

Density:

2.8 g/cm³

- Copper Alloy C3604

Copper Alloy C3604

Copper Alloy C3604 is a free-cutting brass with excellent machinability, corrosion resistance, and strength, ideal for precision parts and fittings.

Density:

8.9 g/cm³

- Aluminum Alloy 5000

Aluminum Alloy 5000

The 5000 series aluminum alloys are magnesium-based alloys known for excellent corrosion resistance, good weldability, and moderate to high strength. They are widely used in marine, automotive, and structural applications.

- AL1070

AL1070

AL1070 is a commercially pure aluminum with very high electrical and thermal conductivity, excellent corrosion resistance, and good workability. It is commonly used in electrical conductors, heat exchangers, and chemical equipment.

- Aluminum Alloy AL2024 / A2024-T6

Aluminum Alloy AL2024 / A2024-T6

AL2024 is a high-strength aluminum-copper alloy widely used in aerospace and structural applications. The T6 temper means it is solution heat-treated and artificially aged to achieve high mechanical strength. It offers excellent fatigue resistance but moderate corrosion resistance, so surface protection is usually necessary.

- Aluminum Alloys AL7075 / 7050 / 7451

Aluminum Alloys AL7075 / 7050 / 7451

Aluminum Alloys 7075, 7050, and 7451 are high-strength zinc-based materials with excellent fatigue resistance, widely used in aerospace, defense, and high-performance structural applications.

Density:

2.8 g/cm³

- Imported Aluminum Alloy 5083

Imported Aluminum Alloy 5083

Aluminum Alloy 5083 is a high-strength, corrosion-resistant alloy ideal for marine, automotive, cryogenic, and structural applications.

- Imported Aluminum Alloy 6082

Imported Aluminum Alloy 6082

Aluminum Alloy 6082 is a medium-strength heat-treatable aluminum-magnesium-silicon alloy, widely used in structural and engineering applications. It offers good corrosion resistance, excellent weldability, and good machinability. Imported 6082 generally meets strict international standards for quality and performance.

- Imported Aluminum Alloy 7075

Imported Aluminum Alloy 7075

Imported Aluminum Alloy 7075 is a high-strength, aerospace-grade material with excellent fatigue resistance and toughness, widely used in aerospace, defense, and performance engineering.

- Imported Aluminum Alloy 6061-T561

Imported Aluminum Alloy 6061-T561

6061-T561 is a heat-treated aluminum-magnesium-silicon alloy known for good mechanical strength, excellent corrosion resistance, and very good machinability. The T561 temper indicates it has been solution heat-treated, stress relieved by stretching, and artificially aged. It is widely used in structural parts, automotive, and precision components. Imported material meets strict international standards for quality and consistency.

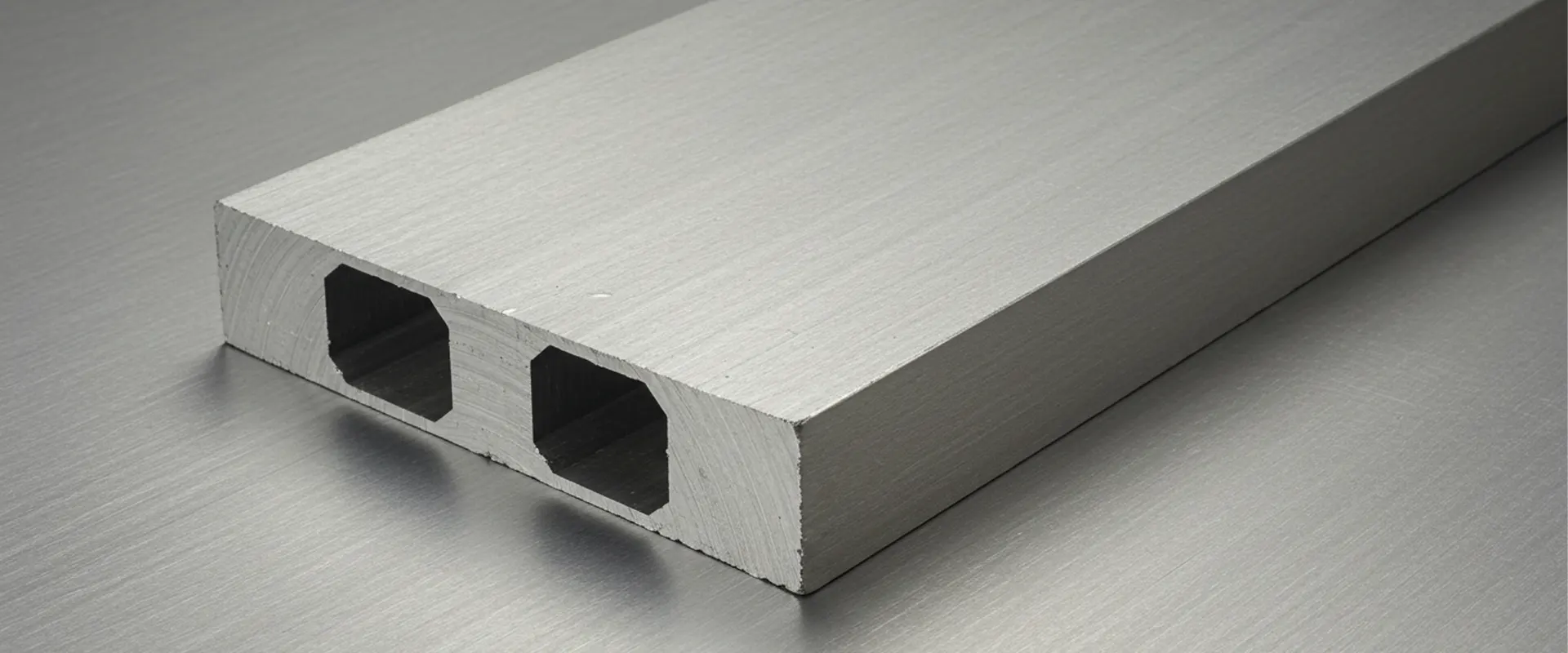

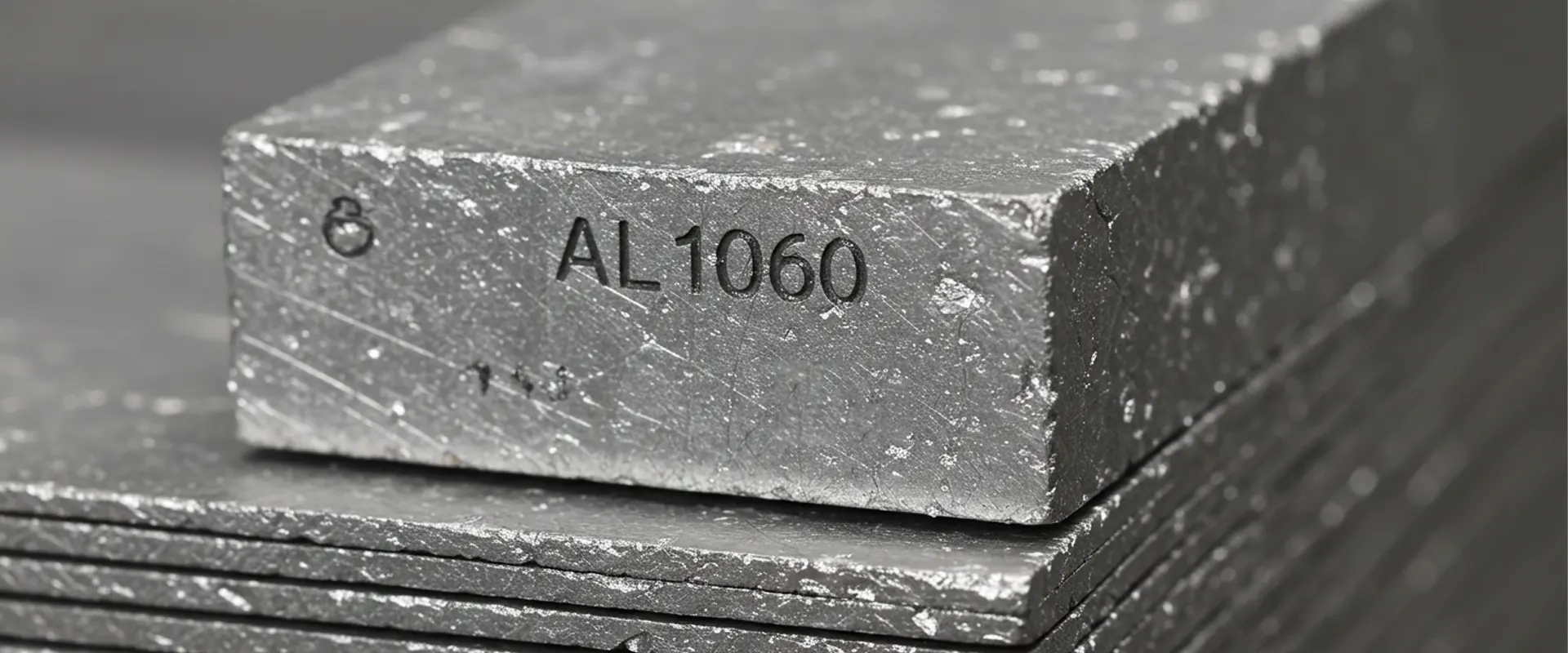

- AL1060

AL1060

AL1060 is a commercially pure aluminum alloy with an aluminum content of about 99.6%. It has excellent electrical and thermal conductivity, outstanding corrosion resistance, and very good formability. Commonly used in electrical conductors, chemical equipment, and sheet metal parts.

- 2A14

2A14

2A14 is a high-strength aluminum-copper alloy with good heat treatability and excellent mechanical properties. It offers good machinability and moderate corrosion resistance, making it suitable for aerospace structural parts, high-load components, and precision engineering.

Density

8.0

- C2801P-1/2H

C2801P-1/2H

C2801P is a brass alloy with around 60% copper and 40% zinc, known as "Muntz metal" or alpha-beta brass. The “1/2H” indicates half-hard temper, giving it moderate strength with better formability compared to full hard. It offers good corrosion resistance, good cold workability, and is commonly used for architectural trim, hardware, and decorative parts.

- C1020P machining

C1020P machining

C1020P is a high-purity oxygen-free copper (OFC) with excellent electrical and thermal conductivity, outstanding ductility, and good corrosion resistance. It is widely used in electrical applications, electronic components, and vacuum devices where high conductivity and cleanliness are critical.

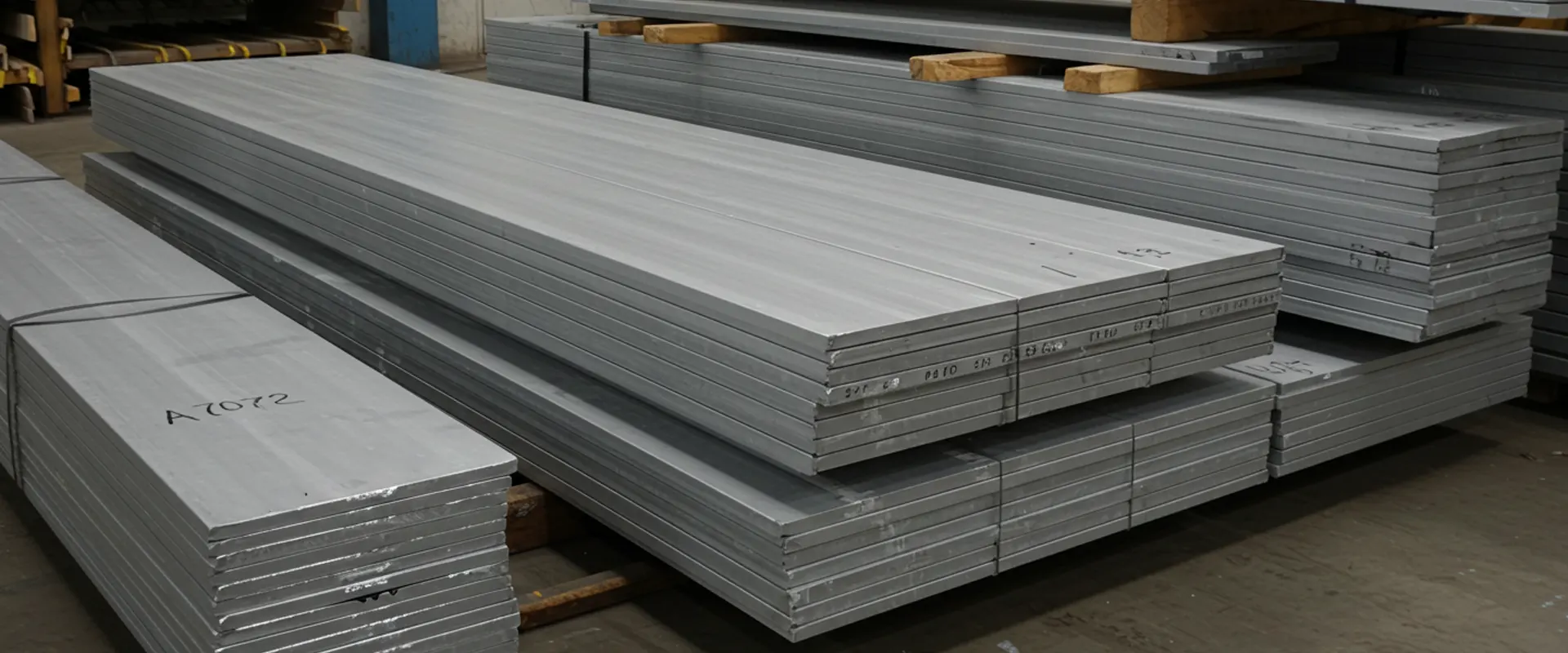

- A7072

A7072

A7072 is an aluminum alloy mainly alloyed with zinc (around 1%) and designed primarily for cladding on heat exchanger tubes and other applications that require good corrosion resistance. It has excellent corrosion resistance, good formability, and is often used as a cladding layer on high-strength core alloys (like 3003 or 7075) to enhance corrosion protection.

Density:

2.8

- A7000

A7000

The A7000 series refers to high-strength aluminum-zinc-magnesium-copper alloys. Known for excellent mechanical strength and good fatigue resistance, they are widely used in aerospace, military, and high-performance engineering applications. Typical grades include 7005, 7050, 7075, and 7049. While strength is very high, corrosion resistance is moderate, so surface treatments are usually applied.

Density:

2.8

- C1100

C1100

C1100 is a commercially pure copper (also known as electrolytic tough pitch copper, ETP) with very high electrical and thermal conductivity, excellent ductility, and good corrosion resistance. It is widely used in electrical conductors, bus bars, wiring, and heat exchangers.

Density:

8.9

- A2014

A2014

A2014 is a high-strength aluminum-copper alloy known for excellent machinability, good mechanical properties, and fair corrosion resistance. It is often used in aerospace parts, heavy-duty forgings, and precision components requiring high strength and good wear resistance.

Density:

2.8 g/cm³

- Titanium Alloy

Titanium Alloy

Titanium alloys are known for their high strength-to-weight ratio, excellent corrosion resistance, and good biocompatibility. They are widely used in aerospace, medical implants, chemical processing, and high-performance engineering applications. Despite being lightweight (density about 4.6 g/cm³), titanium alloys offer superior mechanical properties and resistance to extreme environments.

Density:

4.6

- 7075

7075

7075 is a high-strength aluminum-zinc-magnesium-copper alloy, widely used in aerospace, military, and high-performance engineering parts. It features excellent mechanical strength and fatigue resistance, with moderate corrosion resistance—so it’s often treated with anodizing or coatings.

- A2011

A2011

A2011 is a free-machining aluminum-copper alloy known for excellent machinability and good mechanical strength. It is often used for high-speed automatic lathes, precision turned parts, and screw machine products. It offers fair corrosion resistance and is typically used where complex shapes and fast production are required.

Density:

2.8 g/cm³

- A2024

A2024

A2024 is a high-strength aluminum-copper alloy, widely recognized for its excellent fatigue resistance and good machinability. It is commonly used in aerospace structures, rivets, and precision components requiring high strength-to-weight ratio. While it has good mechanical properties, its corrosion resistance is moderate and often needs protective coatings.

Density:

2.8 g/cm³

- A7050

A7050

A7050 is a high-strength aluminum-zinc-magnesium-copper alloy designed mainly for aerospace structural applications. It offers very high strength, excellent fracture toughness, and good stress corrosion cracking resistance—making it suitable for thick sections and critical parts. Its overall corrosion resistance is better than some other 7000 series alloys like 7075.

Density:

2.8 g/cm³

- 11SMn30

11SMn30

11SMn30 is a free-cutting non-alloy steel with added sulfur (~0.27–0.33%) to improve machinability. It offers very good machinability, making it ideal for high-volume production of turned parts, screws, and fittings. However, due to higher sulfur content, its weldability and toughness are limited.

Density:

7.9 g/cm³

If you do not see the material stock you are looking for, please choose "Custom" under the material drop-down on your quote page and submit for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required. contact us

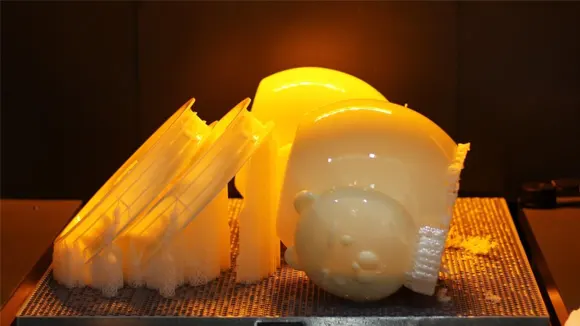

Small Molded Parts within Days

Our complete CNC aluminum service will accompany your aluminum machining project from the prototype construction to the end aluminum parts manufacturing.

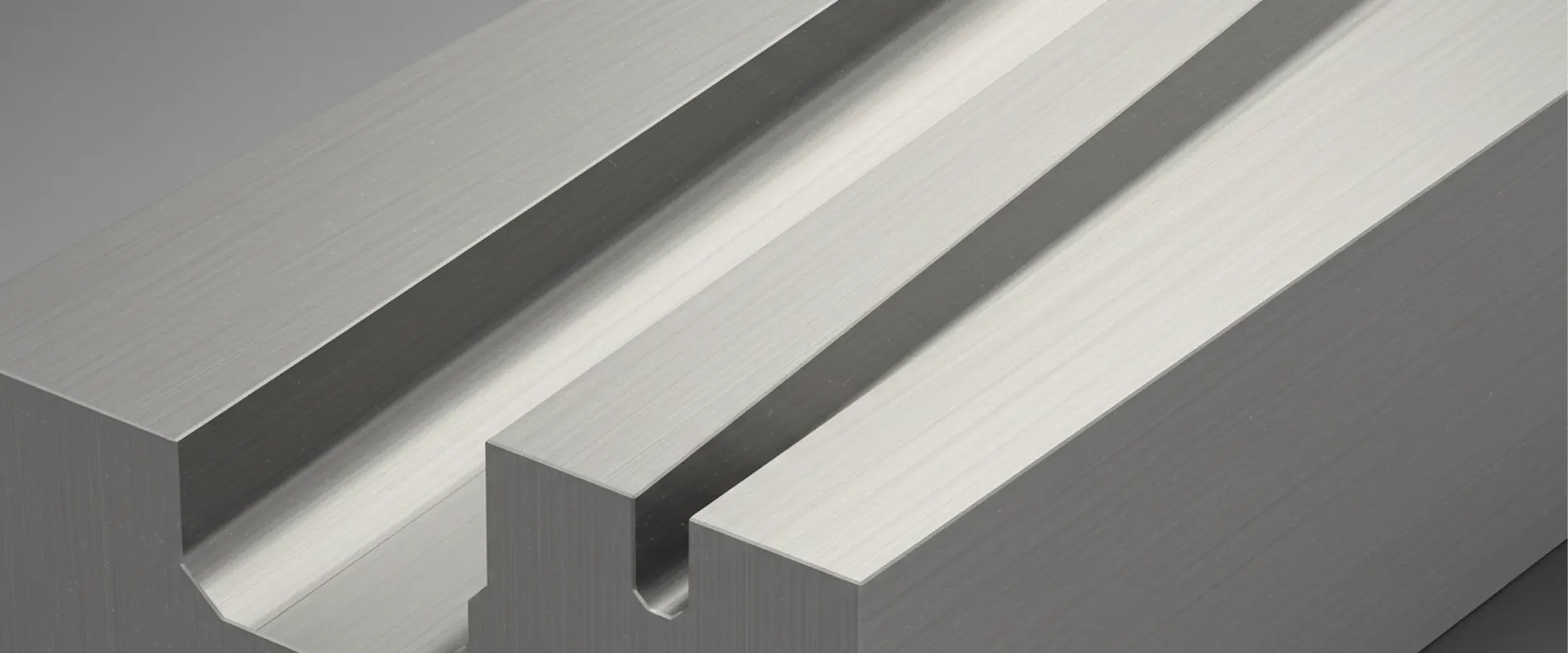

Surface Finishing Options

Our progressive stamping process supports a range of finishing options to improve both functionality and appearance. From deburring and plating to painting and surface treatments, we tailor finishes to meet specific performance, aesthetic, and industry requirements.

| Name | Description | Services | Applicable Materials | |

|

Machined Surface | Economical finish left directly from CNC machining, visible tool marks remain. | CNC milling & turning | Metals, plastics |

|

Anodizing | Enhances corrosion and wear resistance; can be dyed, ideal for aluminum parts. | Type II & Type III anodizing | Aluminum |

|

Polishing | Achieves high gloss, reduces surface roughness, and improves metallic aesthetics. | Manual or mechanical polishing | Metals |

|

Sandblasting | Uses pressurized media to clean and texture the surface, creating an even matte effect. | Bead blasting / sandblasting | Metals, plastics |

|

Brushed Finish | Creates a unidirectional satin texture, reducing the visibility of scratches and marks. | Brushing | Metals, some plastics |

|

Powder Coating | Applies a thick, durable, wear-resistant layer with excellent color and texture options. | Electrostatic powder coating | Metals |

|

Electroplating | Bonds a thin metal layer to improve wear resistance, corrosion resistance, and surface conductivity. | Chrome, nickel, zinc plating, etc. | Metals |

|

Black Oxide | Conversion coating for ferrous metals that improves corrosion resistance and reduces light reflection. | Black oxide treatment | Steel, stainless steel |

|

Electropolishing | Electrochemical process to smooth and brighten the surface, enhancing corrosion resistance. | Electropolishing | Stainless steel, other metals |

|

Alodine | Chromate conversion coating providing corrosion protection and improved paint adhesion, mainly for aluminum. | Chromate coating (Alodine) | Aluminum |

|

Heat Treatment | Alters mechanical properties, increasing hardness, strength, or ductility. | Vacuum heat treatment, tempering | Metals (steel, aluminum, etc.) |

If you do not see the surface finish you are looking for, please choose “Custom” on the quote page. After specifying features, tolerances, inspection requirements, and quantities, submit for an expert engineering review — or simply contact us for support.

Why GD Prototyping for Stamping Dies

Partnering with GD Prototyping for your progressive stamping die projects means gaining access to a team that delivers precision, efficiency, and reliable performance. From material versatility and fast turnaround to expert engineering support, we ensure every stamped part meets your functional, aesthetic, and cost expectations—on time and to spec.

-

Efficient & Scalable Production

Progressive stamping is ideal for high-volume, repeatable part production with reduced labor and faster cycle times.

-

High-speed production for mass manufacturing

-

Simplified operations with consistent output

-

Scalable for small to large batch volumes

-

-

Consistent Precision & Quality

Stable dies and automation ensure precise dimensions and consistent surfaces for every stamped part.

-

Tight tolerances and stable quality

-

High repeatability across thousands of runs

-

Excellent surface finish with minimal secondary work

-

-

Versatile Materials & Applications

Works with various metals and serves industries from automotive to electronics.

-

Supports steel, aluminum, copper, and alloy materials

-

Applied in automotive, medical, appliance, and more

-

Cost-effective for both functional and decorative parts

-

Join Over 3,000 Companies Using GD for Quality Parts

Explore real-world case studies from our customers that showcase the power of our manufacturing capabilities to drive product development.

Precision Stamping for Product Developers

Showcasing high-efficiency progressive stamping technology designed for scalable, cost-effective production of complex metal parts across automotive, electronics, medical, and more.

-

Automotive Bracket Stamping

Progressive dies shape complex automotive brackets from high-strength steel, ensuring consistent precision and fast production for large-volume output.

-

Consumer Electronics Components

Using copper or stainless steel, intricate connector parts are stamped with fine tolerances and high repeatability—perfect for compact electronics.

-

Aluminum Alloy Cover Plates

Progressive dies efficiently stamp lightweight aluminum covers for appliances or medical devices, balancing strength, surface finish, and material savings.

Frequently Asked Questions

Here are answers to common questions about industrial PCs and automation solutions. Need more details? Contact our experts at sales08@gd-prototype.com

-

What services does GD Prototyping offer?

-

What industries do you serve?

-

What materials can you work with?

-

How fast can I get a quote?

-

What’s your typical lead time?

What Our Customers Say

Customized Process

With years of manufacturing experience, GD Prototyping provides the best solutions for all rapid prototyping and low-volume manufacturing needs. We simplify the innovation cycle into four simple but effective steps.

Flexible Design Iterations

Creating low volume manufacturing allows for more efficient verification of design, engineering and manufacturability.

Short Turnaround Times

Tooling is cost-effective for low volume manufacturers to handle orders quickly and flexibly, with no minimum order quantities.

Close the Production Gap

Low-volume pilot runs bridge the gap between prototype and production, identifying and resolving any issues before entering series production.

Reduced Time to Market

Low-volume manufacturing services optimize the connection between production, supply chain and consumers, providing fast time-to-market for new products.

Get Your Parts Into Production Today

Our complete CNC aluminum service will accompany your aluminum machining project from the prototype construction to the end aluminum parts manufacturing.

At GD Prototyping, our Progressive Stamping Die solutions enable high-speed, high-accuracy sheet metal part production. This method uses a series of stamping stations within a single die set, performing multiple operations—such as punching, bending, and forming—in one continuous process. The result is a streamlined manufacturing workflow that produces uniform, high-quality parts at scale. Progressive dies are particularly effective for complex components requiring tight tolerances, repeatability, and cost efficiency. By integrating multiple forming steps into one tool, the process reduces waste, shortens lead times, and lowers per-part production costs. With expertise in die design and advanced tooling, GD Prototyping delivers reliable solutions for industries that demand precision and volume. Whether for automotive parts, electrical connectors, or consumer goods, our progressive stamping dies provide durability, accuracy, and productivity, helping clients achieve consistent quality across large production runs.

Applications of Progressive Stamping Die

- Automotive Components – Produces brackets, clips, and structural sheet-metal parts.

- Electrical & Electronics – Manufactures terminals, connectors, and housings.

- Industrial Equipment – Provides high-strength stamped components for machinery.

- Consumer Products – Creates small precision parts for appliances and gadgets.

- Aerospace – Delivers lightweight stamped parts with high repeatability.

- Telecommunications – Produces metal parts for connectors and communication devices.

- Hardware & Tools – Forms fasteners, springs, and other durable components.

- Packaging Industry – Stamps precision metal parts used in packaging machinery.