Precision Automotive Parts Machining | CNC Auto Components

Concepts of Precision Automotive Parts Machining

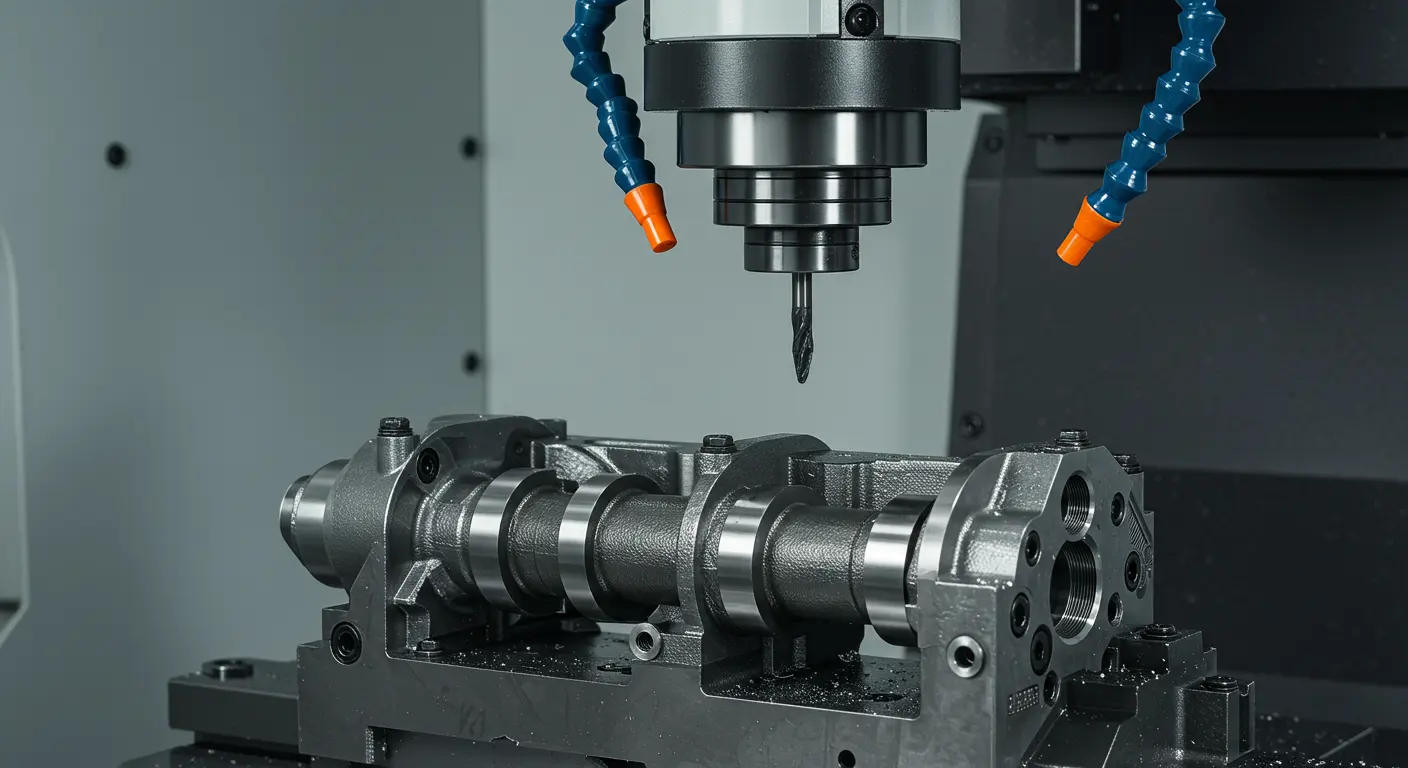

Precision automotive parts machining entails the production of complex parts of a vehicle using computer numerical control (CNC) machines. These systems are used to steer the cutting tools with greater accuracy (micrometers) to achieve high precision metalworking, and these systems are capable of meeting the demanding requirements of the automotive industry.

Such an approach is at the heart of automotive parts production, whereby complex design, changing geometries, and fine tolerances are an absolute requirement. Engineers are able to produce tailor-made machined parts by means of CNC turning and milling operations of numerous products, such as aluminum, titanium, stainless steel, and high-strength alloys.

Applications of CNC Precision Machining in the Automotive Industry

In the modern competitive world, quality and innovation in the automotive sector are characterized by the precision machining of automobiles. With the integration of AI-based optimization and automated machining systems, manufacturers obtain precision that would have previously been inconceivable.

- With the help of multi-axis CNC machining, intricate items such as engine blocks, gearbox housings, suspension parts, and chassis are produced with flawless alignment, along with other high-quality surface finishes. These technologies are crucial in maintaining the dimensional consistency and the micron-level accuracy in all production batches.

- Moreover, the automotive industry will have its machining done using CNC, which is efficient and reliable. It allows high-speed milling of aluminum components, increases the rate of material removal (MRR), and decreases the rate of tool wear, so that every component has to be within the tolerance of +-0.01mm machining.

- In GD-Prototypes, we are a team of custom automotive machining, where precision engineering is combined with advanced manufacturing technology to serve and support automotive OEMs and aftermarket industries.

Automotive Precision Machining Materials

Material selection is an important factor in determining the success of the custom automotive parts manufacturing. Every element needs a strength/weight/machinability equilibrium. The most widely used materials are:

Lightweight, Yet Hard, Aluminum Precision Machining: Engine blocks and housings.

Stainless Steel Automotive Components: These are utilized in exhausts, valves, and drive systems because they are corrosion-resistant.

Titanium Automotive Parts: Titanium automotive parts are necessitated by high-performance vehicles that need heat resistance and strength.

Machining of Brass and Copper: This is used in electrical and fuel systems to provide better conductivity.

Machining Composite Materials: It is appropriate in contemporary lightweight body and interior systems.

The process of heat treatment and finishing of surface finishes of automotive-grade materials to attain the best hardness, wear, and outlook is done under stringent requirements.

The Technology and Process of High Precision Machining

The process of transforming a concept into a component includes a variety of highly sophisticated machining operations, which add up to accuracy and reliability. Key techniques include:

Vehicle CNC Turning and Milling: High speed, precision cylindrical and prismatic parts.

Precision Drilling and Boring: Provides smooth internal geometries of engine and transmission components.

Surface Finishing/Polishing: Obtains the required Ra surface roughness as a result of high-performance and beauty.

Optimization of Toolpaths: Decreases cycle time and provides a consistent dimensional result.

CAD/CAM Programming: Translates 3D designs to accurate tool motions.

State-of-the-art machining technologies: Incorporates automation, real-time monitoring, and IoT-equipped CNC machines to bring about smooth production.

Automotive Engineering Applications

Precision machining assists most of the subsystems in a vehicle. Some typical applications are:

- Cylinder heads and engine blocks.

- Components of transmission and gearboxes.

- Suspension system parts

- Drivetrain components

- Brake system parts

- Fuel system components

- Chassis and frame parts

Steering System Components

The parts are then tested in terms of dimensional accuracy, tolerance verification, and quality control inspection, to make sure that they are up to IATF 16949 requirements, and pass ISO 9001 certified machining.

Through a combination of geometric dimensioning and tolerancing (GD&T), engineers can be assured that all components will be able to perform perfectly, even with the increase of mechanical loads and temperatures.

Prototype to Production: Custom Automotive Machining Solutions

During the developmental stage of the design, automotive prototype machining allows the engineer to test ideas prior to mass production. Manufacturers can test their designs through digital twin and rapid prototyping to simulate performance, find weaknesses, and optimize designs.

At GD-Prototypes, we provide the solution between prototype machining and production machining in terms of volumes, which are flexible to both start-ups and established OEMs. We have custom-designed automotive parts machining solutions that provide our customers with the individualized treatment of every project - from design optimization to full-scale production.

The solution helps in innovation, reducing the development cycle, and improving the performance of the entire product.

Automobile Parts Machining Quality Assurance

Any company in the business of machining automotive parts is defined by quality. Dimensional accuracy is observed at every stage by statistical process control (SPC) and precision measurement systems.

CMM (Coordinate Measuring Machines), laser scanners, and optical comparators are used to check automotive components to verify features that are at microscopic scales. This guarantees repeatability in production and a reduction of the error rates.

This is because of constant refinements in machining, the manufacturers have a culture of excellence - all parts are designed to perform with high precision and are optimized by the use of advanced CNC technology.

Advantages of Precision Parts Automotive Machining

Unmatched Accuracy

Precision machining ensures there is a dimension consistency of +-0.01mm, hence tolerance.

Enhanced Durability

Components using heat treatment and surface finishing become resistant to wear and extreme conditions.

High Efficiency

Optimizing the high-speed machining processes and tool wear minimizes the cycle time and enhances productivity.

Design Flexibility

Multi-axis CNC machining makes it simple to get complex designs and curved geometries.

Innovation Support

The CAD/CAM and AI-based systems increase the speed of development between ideas and market-ready prototypes.

Collaborating with a Reliable Automotive Machining Supplier

It is essential to select a partner who can be trusted within the automotive manufacturing ecosystem. The precision CNC shop is not only an expert in providing technical knowledge but also offers end-to-end support, such as design validation up to post-production.

GD-Prototypes is a company that specializes in making automotive parts on order and provides full-service machining of automotive components. We have the highest standards in all our projects with advanced CNC machining centers, high-speed milling systems, and a promise of quality that is approached through ISO certification.

You may require CNC-machined parts to be used in car engines, machining of aluminum parts, or even how to develop a prototype; we offer custom engineering solutions of your requirements to suit your performance interests.

Conclusion

Accurate Precision automotive parts machining remains a way of reinventing the way in which cars are designed, manufactured, and optimized. Through the combination of intelligent production, AI-powered CNCs, and environmentally friendly machining, manufacturers are not merely attaining excellence but establishing new trends in mobility on a global scale. Whether it is engine blocks, drive train, or any other part, every part is highly machine-crafted, indicating an approach to innovation, precision, and mastery of engineering. By associating with a proven automotive machining player such as GD-Prototyping, you are guaranteed that your projects are going to be executed to perfection, technology-driven driven and performance-based.