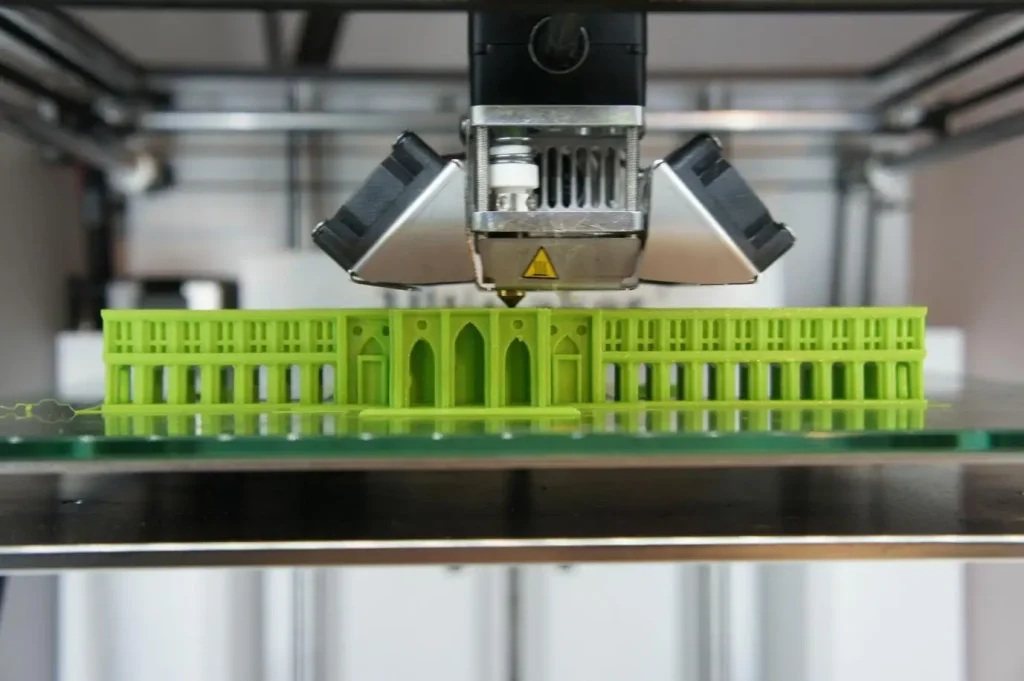

Can Plastic 3D Printing Services Replace Traditional Molding?

Plastic 3D Printing Services are rewriting how parts move from CAD to hand. Teams want speed. Finance wants lower risk. Operations wants fewer delays. But one question hangs over every kickoff: can these services replace traditional molding? On paper, the promise looks real - no tooling, faster loops, complex shapes. In practice, trade-offs appear in strength, finish, and scale. Some parts fly. Others fall short. The gap is often not the tech, but the use case. Today, we unpack the truth behind the headline. We'll test speed, cost, quality, and volume. The answer may surprise you. Keep reading.

The Real Question: Can Plastic 3D Printing Services Replace Molding?

Manufacturers ask us a direct question: can Plastic 3D Printing Services replace traditional injection molding? The honest answer is "yes - sometimes, and for the right stage." Molding still wins when you're shipping hundreds of thousands of identical parts at the lowest unit cost. But before you cut steel, you face long lead times, high tooling spend, and designs that freeze too early. That is exactly where Plastic 3D Printing Services shine.

Our approach is simple: turn your CAD into parts quickly, learn fast, and delay irreversible decisions. We support SLA, SLS, and FDM for plastics, with layer resolutions from 25–200 microns and typical tolerances of ±0.1–±0.3 mm. Need large parts for housings or fixtures? We can print up to 1000 mm (material-dependent), which reduces splitting and bonding. After printing, we deliver production-like cosmetics - sanding, painting, polishing, and even plating for assemblies with mixed materials - so prototypes look like products, not lab samples.

Where molding requires tooling, DFM loops, and minimum order quantities, Plastic 3D Printing Services convert files to parts without waiting for molds. That lets your team validate form, fit, and function while ideas are still flexible. If feedback forces a change tomorrow, you revise the model and reprint. No sunk tooling cost. No schedule reset.

✅ Pain Points We Solve In Week One

• Long quote and tool-build queues that stall design reviews

• Expensive tooling changes when feedback arrives late

• Complex internal features that are costly or impossible to mold

• Small pilot runs and regional customization that punish unit economics

How Plastic 3D Printing Services Stack Up Against Molding

When you compare processes, look at speed, geometry, and cost through the lens of risk.

- Speed & Iteration

Tooling can take weeks, and every tweak triggers rework. Plastic 3D Printing Services compress that calendar into days. You can test three concepts in parallel, run a user study on Friday, and revise geometry for Monday. More learning cycles per week means fewer surprises at EVT/DVT. For leadership, that speed turns "we think it works" into "we know it works," backed by physical parts.

- Geometry & Customization

Conformal cooling, organic lattices, and hidden internal ducts are either difficult or expensive in molding. Add in draft angles and parting lines and the design often compromises performance. With Plastic 3D Printing Services, we build those features directly. Supported processes can hit fine layers down to 25 microns, enabling crisp details and lightweight structures. If you need ten variants for a fit study or five region-specific SKUs, you print them - no extra setup, no new tools.

- Cost & Volume

Think of molding as fixed cost first, variable cost later. Think of 3D printing as variable cost from day one. For low volumes, pilot runs, service parts, and early market tests, Plastic 3D Printing Services often win on total landed cost because there's no tooling to amortize. When demand stabilizes and the design stops changing, moving to molds can drop unit price. Many of our customers follow a hybrid path: print to prove, then mold to scale - while keeping 3D printing for spares, late design options, and high-mix low-volume parts.

When To Choose Each - And How GD Prototyping Bridges The Gap

Selecting a process is really about risk, time, and certainty. Use molding when forecasts are firm and designs are frozen. Choose Plastic 3D Printing Services when you need speed, learning, or design freedom. Most programs will use both - by design.

At GD Prototyping, we map the path from sketch to scale:

• Rapid Prototyping, Not Guessing: Send CAD; we review geometry, pick the right process (SLA for smooth surfaces and fine detail, SLS for durable mechanisms with minimal supports, FDM for fast jigs, fixtures, and large parts), and suggest a finishing plan.

• Data You Can Hand To Production: We target ±0.1–±0.3 mm on most features, then document critical-to-quality dimensions so your molder starts with evidence, not assumptions.

• Realistic Materials & Cosmetics: Plastics and resins cover most prototype needs; composites are available for stiffness; metal inserts can be combined for threaded or load-bearing interfaces. Need presentation-ready parts? We match colors and textures with sanding, painting, and polishing.

• Scale-Up Without Drama: Once performance is proven, we help convert learnings into DFM guidance, so tooling trials require fewer loops and less rework.

Not every part should be printed. But many should be printed first. Early 3D prints cut through the slowest step in traditional development - the decision to lock the design too soon. You collect user feedback on the version that will actually ship, not a look-alike. You confirm assembly stack-ups and tolerance chains before they collide with real hardware. You expose risks while they're cheap to fix.

✅ Practical Triggers For Choosing 3D Printing First

• You need executive demos or investor-ready samples next week

• Iteration speed matters more than piece price this quarter

• The part contains trapped cavities, lattice infill, or complex internal routing

• Volume is uncertain or intentionally low (engineering pilots, service parts)

• You want market feedback across multiple variants before committing to steel

✅ Where Molding Still Wins

• Stable, high-volume demand with tight unit-cost targets

• Simple geometries that thrive with standard tool design

• Materials or surface textures specified by a legacy product line

What To Expect Working With GD Prototyping

We keep the process clear and fast. You'll receive a manufacturability review that flags risks early: thin walls, unsupported spans, hole sizing, anisotropy, and post-processing impacts. We explain trade-offs in plain language and give you a plan you can share with design, quality, and procurement. If scale-up is on the horizon, we advise on gate locations, draft, and knit line concerns so your toolmaker starts strong.

Behind the scenes, our digital workflow turns your models into parts without manual bottlenecks. Automated preparation, process-specific tuning, and in-process checks help hold the targets you care about - surface finish for cosmetic panels, dimensional fidelity for snap-fits, and repeatability for test fixtures. The result is simple: parts that behave like the product you intend to ship.

Call To Action: Ready to decide between printing and molding for your next build? Upload your CAD to GD Prototyping for a free manufacturability review and same-day quote. We'll recommend the right path - leveraging Plastic 3D Printing Services for speed and learning, and outlining a clean bridge to tooling when volume and certainty rise. Build smarter now, scale with confidence later.