How Plastic 3D Printing Services Cut Prototyping Costs Fast

Plastic 3D Printing Services help product teams cut waste, compress lead times, and validate designs without the burden of tooling. At GD Prototyping, a world-class certified contract manufacturer, we focus on rapid prototyping, low-volume, high-complexity, and highly flexible production across precision machining, assemblies, and integrated systems. This article explains, in practical terms, how our approach lowers prototype cost while keeping quality high and schedules predictable.

Why Plastic 3D Printing Services Reduce Total Prototype Cost

Traditional prototype routes are weighed down by tooling, queue times, and minimum order quantities. Each small design change can trigger another quote round, another delay, and another invoice. Plastic 3D Printing Services remove those hurdles by building parts directly from CAD. You pay for parts you actually need, not for molds that may be obsolete after the next iteration.

In day-to-day development, this matters. Teams can test early, learn faster, and make decisions with real data rather than assumptions. For programs operating under tight launch windows or limited budgets, low-volume plastic prototyping services and rapid plastic prototype manufacturing offer a cleaner path from concept to customer feedback - without giving up accuracy, surface quality, or mechanical confidence.

- Fast Turnaround: Prototypes delivered within 1 - 2 days so sprints stay on track.

- Cost-Effective: No molds to cut; assembly steps and change-order fees are minimized.

- Design Flexibility: Complex interiors, living hinges, and lattice features printed with ease.

- Wide Material Selection: Plastics and metals supported for hybrid, multi-process builds.

These gains translate into fewer meetings, quicker approvals, and tighter feedback loops. Budget shifts from waiting to learning, which is where it creates the most value.

A Practical Workflow That Scales

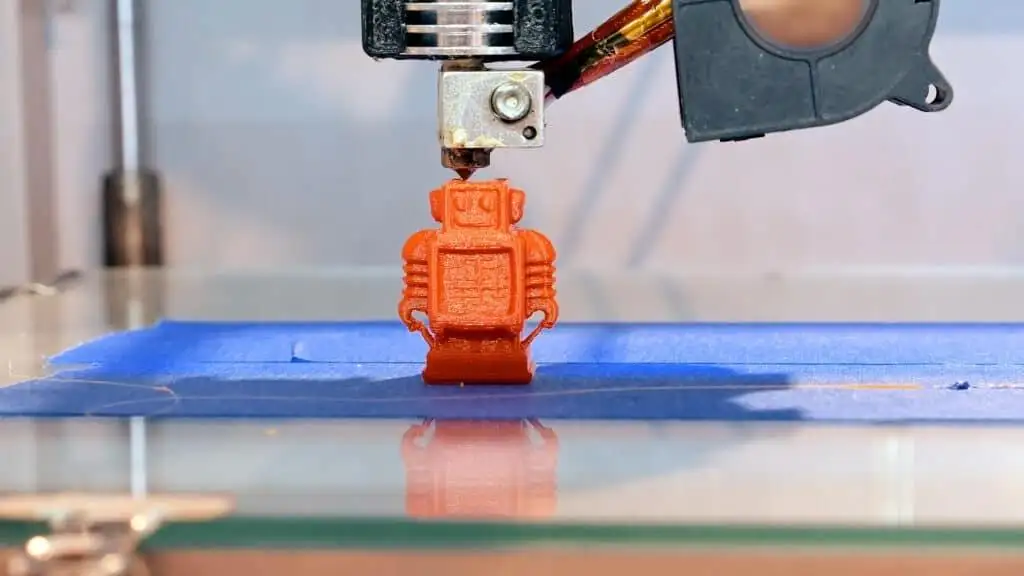

Our 3D printing center brings together SLA, SLS, MJF, and SLM/DMLS to cover both plastic and metal applications - from show-and-tell models to rugged, functional parts. Every build follows a straightforward, transparent flow: project intake and DFM guidance → technology/material selection → printing → finishing → inspection and documentation. The result is repeatable quality, delivered fast.

SLA For Visual Precision

SLA cures photosensitive resin layer by layer with a UV laser. It excels when you need smooth surfaces, crisp lettering, and fine detail for demos, dental models, and dimensional fit checks. Parts have a premium look right off the platform. When the application calls for it, clear or painted finishes elevate the presentation without masking critical features.

SLS & MJF For Functional Nylon

SLS fuses nylon powder without supports, unlocking internal channels and complex assemblies that would be impossible - or very expensive - by other means. MJF adds high throughput and consistent mechanical properties. Together, they are ideal for brackets, enclosures, ducting, and snap-fits where heat resistance and durability matter. They're also a smart choice for pilot builds that need production-like behavior before full tooling.

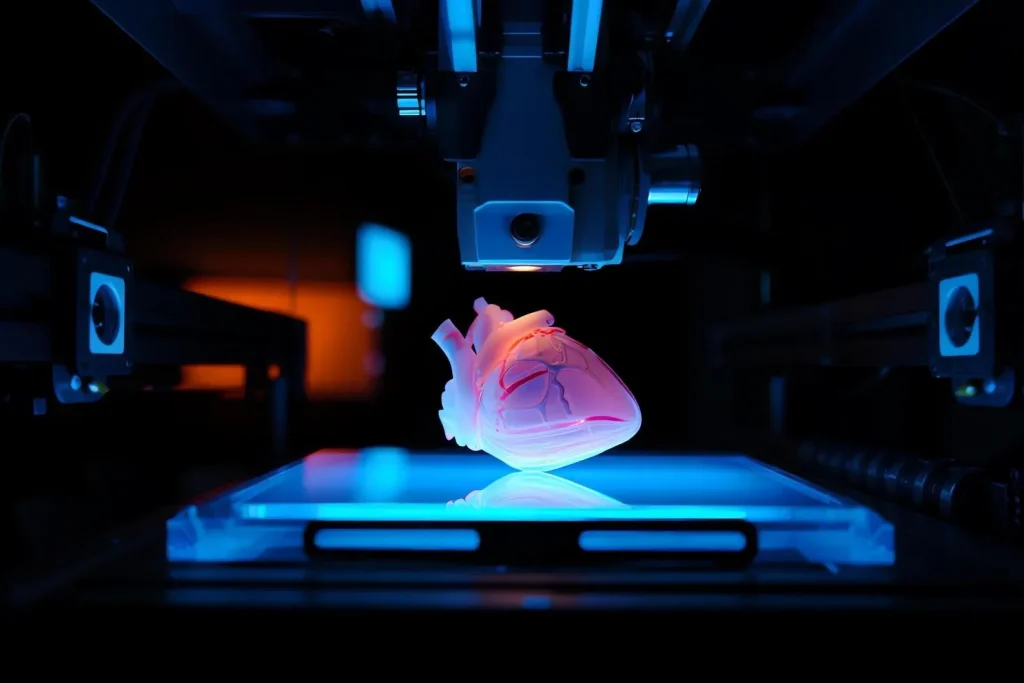

SLM/DMLS For Metal Strength

Some designs demand metal. Our metal printing options create dense, high-strength parts in stainless steel, aluminum alloys, or titanium. This is a strong fit for aerospace, medical, mold inserts, and industrial components. Pairing metal components with Plastic 3D Printing Services allows you to evaluate a complete system early, reducing assembly risk before you commit to capital tooling.

Finishing That Looks Production-Ready

A convincing prototype needs the right finish. We offer options aligned to your stage gate:

- Standard Finish for cleaned, smoothed parts ready for general review.

- Painting & Clear Coating to match brand color, gloss, and protection for demos.

- Polishing & Vapor Smoothing for high clarity and gloss, especially with ABS/ASA or clear resins.

- Dyeing & Bead Blasting for even color and matte textures on nylon parts.

- Electroplating & Heat Treatment when appearance, conductivity, or metal strength is the priority.

Behind the scenes, every part is inspected and tested with photos and reports before shipment, so results are consistent across iterations and builds.

Scale Smart

The fastest way to cut cost is to prevent rework. Our engineers provide practical DFM guidance up front - adjusting wall thickness, adding ribs, refining hole sizes, and tuning living hinges - so parts print cleanly and perform as intended. The same mindset applies to materials. We help you select the right polymer for the job, including ABS, PMMA, POM, PP, PC, Nylon (PA6/PA66), ABS+PC, PC+ABS, Transparent ABS, and others, so you can test the behavior that matters without surprises.

Teams usually come to us with the same pain points. We address them head-on:

- Late Design Changes: Print overnight, test the next day, revise within the week.

- Assembly Stack-Ups: Merge features into a single printed body to reduce fixtures and fasteners.

- Surface Quality Issues: Choose SLA or apply polishing/painting for showroom-ready models.

- Supply Chain Delays: Local, flexible capacity keeps your build plan moving.

When it's time to bridge from prototype to pilot, our small-batch production keeps the same digital thread. Geometry stays under control, tolerances remain tight, and documentation follows each lot. That continuity lowers the risk of transferring lessons learned - and it shortens time to a confident release.

Why GD Prototyping

We combine fast delivery (3D printing lead times starting from 48 hours), flexible scaling from single units to short runs, high precision with tight tolerances, and professional finishing options. Our comprehensive approach integrates plastics and metals when your system requires both, giving you a single, accountable partner for complex, multi-process builds.

Your Next Move

If you're ready to cut prototype spend and clear your approval path, request a free DFM review from GD Prototyping. We'll recommend the best fit among SLA, SLS, MJF, or SLM/DMLS, plus a material and finishing plan aligned to your schedule and budget. Start with one part or a small assembly - our Plastic 3D Printing Services scale with your program and adapt as your design evolves.

Bottom Line: Product teams don't just need parts; they need traction. By eliminating tooling, shrinking lead times, and enabling fast, informed iteration, Plastic 3D Printing Services convert ideas into evidence - quickly and cost-effectively. With GD Prototyping as your partner, you move from first sketch to confident pilot faster, with clearer data and fewer surprises.