Metal 3D printing principles and applications

Metal 3D printing, also known as metal additive manufacturing, is a process of stacking metal materials layer by layer to create actual objects through digital technology. Its basic principle is driven by a computer-aided design (CAD) model, and metal powder is melted and solidified layer by layer through a high-energy laser beam, electron beam or heat source to finally form the desired product.

Classification of metal 3D printing technology

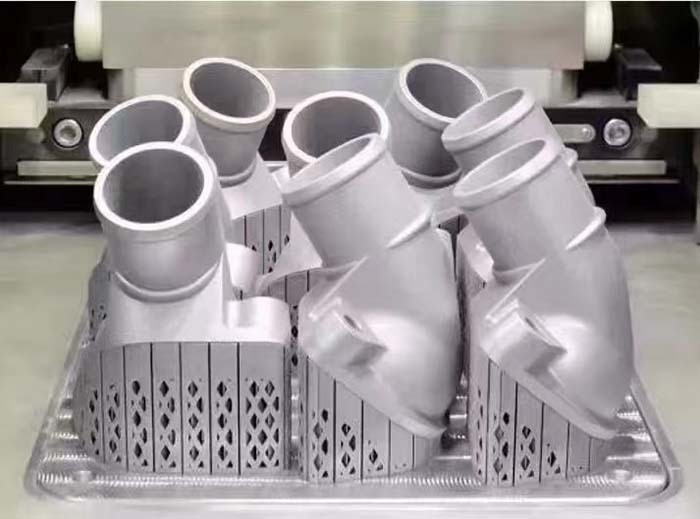

1. Selective laser melting (SLM): Metal powder is selectively melted by a laser beam to form the outline of the part, and then stacked layer by layer to finally obtain a complete metal part.

2. Metal powder jetting (Metal Powder Jetting): Metal powder is sprayed onto the workbench, and the powder is melted into the desired shape by heat or laser, and then stacked layer by layer to form a part.

3. Electron beam melting (Electron Beam Melting, EBM): Metal powder is melted using a high-energy electron beam, which is suitable for the production of high-performance metal material parts.

Metal 3D printing technology has a wide range of applications, mainly including the following aspects:

1. Aerospace: Used to manufacture high-performance parts such as engine components and aerospace structural parts.

2. Automobile manufacturing: used to produce automobile parts, such as engine parts, chassis structures, etc.

3. Medical devices: manufacture customized medical devices, such as dental implants, orthopedic repair parts, etc.

4. Jewelry manufacturing: produce personalized and customized jewelry.

5. Industrial field: used to manufacture complex parts such as molds, turbine blades, and piping systems.

Advantages of metal 3D printing

1. Save materials: Through additive manufacturing, only the required parts are printed, which greatly improves the material utilization rate. The material utilization rate of additive manufacturing can reach more than 90% (traditional processing may be less than 50%)

2. High customization: It can produce customized products that meet personalized needs, suitable for small batches and personalized needs (such as medical implants, aerospace customized parts)

3. High production efficiency: simplify the manufacturing process and reduce processing time.

4. Complex geometric molding: It can manufacture internal flow channels and lightweight topological structures that cannot be achieved by traditional processes.

Common metal materials

Titanium alloy (Ti-6Al-4V): used for biocompatibility and high-strength and lightweight requirements.

Stainless steel (316L, 17-4PH): corrosion-resistant, suitable for industrial parts.

Aluminum alloy (AlSi10Mg): lightweight structural parts.

Nickel-based high-temperature alloy (Inconel 718, 625): high temperature resistant, used in aircraft engines.

Cobalt-chromium alloy: wear-resistant, suitable for dental and joint implants.

However, metal 3D printing also faces some challenges, such as high cost, strict technical requirements, and post-processing requirements. In addition, metal 3D printed parts still need long-term verification in terms of mechanical properties and durability.

Future development trends

1. Technological progress: With the continuous advancement of technology, the accuracy and speed of metal 3D printing will be further improved.

2. Material expansion: More metal materials will be developed and applied to 3D printing to meet the needs of different fields.

3. Expansion of application areas: Metal 3D printing will penetrate into more fields, such as construction, shipbuilding, etc.

4. Personalized production: As consumers' demand for personalized products increases, metal 3D printing will play a greater role in customized production.

Metal 3D printing technology has brought revolutionary changes to the manufacturing industry, with a wide range of applications and huge potential. With the continuous advancement of technology and cost reduction, metal 3D printing will play a more important role in the future and promote the sustainable development of the manufacturing industry.