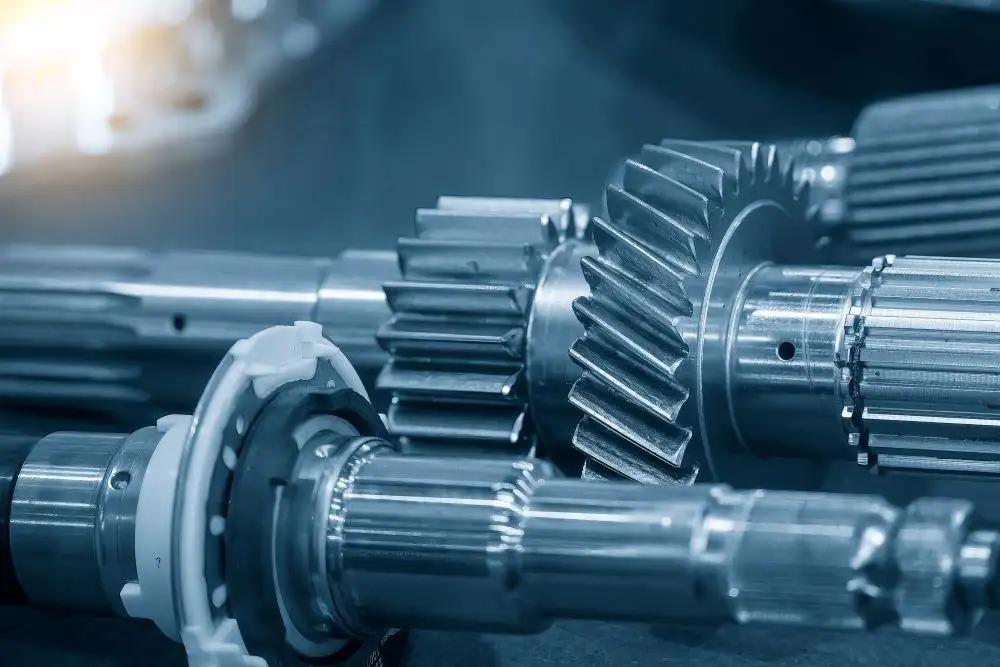

How to Optimize Mechanical Parts Machining for Precision Plastic Parts

Mechanical Parts Machining is the backbone of precise plastic parts. When the master is right, the mold is right. When the mold is right, every part follows. Yet speed, cost, and finish often pull in different directions. How do you balance clean edges, tight fits, and fast lead times? What small setup choices avoid bubbles, warpage, and ugly witness lines? In this post, we share a simple playbook you can use today. We cover toolpaths, tolerances, and mold-ready features. The last tip is the one most teams miss - yet it saves entire pilot runs. Ready to find it?

Why Mechanical Parts Machining Determines Vacuum Casting Accuracy

Vacuum casting moves fast and keeps costs low, but it only performs when the master model is right. Our workflow starts with a master built by CNC or high-resolution 3D printing. That master shapes the silicone mold, and the mold decides what every part will look like. If the master is inaccurate, the error repeats across the entire batch. That is why we treat Mechanical Parts Machining as the foundation, not an afterthought.

During casting, polyurethane resin flows into the silicone mold while a vacuum removes trapped air. The vacuum helps resin fill thin walls, tight corners, and long ribs. The payoff is smooth surfaces and stable dimensions. Good machining makes this even better: we cut clean parting lines, apply the correct draft, and protect small radii so the silicone captures them faithfully. Tight control up front means less sanding, fewer rejects, and a shorter path from idea to usable parts.

✅ Common Pain Points We Eliminate

• Tolerance drift between early prototypes and pilot builds

• Cosmetic waviness on A-surfaces and display panels

• Air traps and short shots from poor venting or gating choices

• Rework loops when late design tweaks collide with deadlines

Silicone molds are productive yet finite tools. A typical mold yields 15–25 parts before precision starts to fade. With a well-machined master, you get consistent parts through the mold's life and more usable units per mold. That performance matters when you need a few dozen parts for verification, user studies, or a quick demo to stakeholders.

How We Optimize Mechanical Parts Machining For Precision Plastic Parts

We shape the master for real casting behavior, not just for a nice CAD render. Choices about toolpath, tolerance, and texture flow directly into the silicone and then into each part.

- Toolpath, Tolerance, Texture

We rough aggressively to control cost and time, then finish with fine step-overs where it counts. Interfaces, snap-fits, and sealing edges get priority tolerances. For cosmetic faces, we tune the surface so parts look molded, not milled. This approach balances speed and finish quality. You see it in fewer witness lines, better fit, and less post-processing.

- Material-Led Details

Polyurethane systems can mimic ABS, polycarbonate, or rubber-like plastics. We pick finishes and edge strategies that match the target behavior:

• ABS-like: crisp edges and stable walls for enclosures and brackets.

• PC-like: polished masters for clear parts and light pipes.

• Rubber-like: generous radii and smooth transitions to reduce stress.

Mechanical Parts Machining lets us bake these choices into the master so the final parts match the feel you expect.

- Moldability Designed In

We model and machine parting lines, gates, and vents into the plan instead of improvising later. If a feature might trap air under vacuum, we adjust the approach angle or add micro-vent positions in the silicone map. The result is a steady casting rhythm and fewer surprises on the bench.

- Built For Fast Iteration

Low-volume programs evolve. When feedback lands, we re-cut the master and build a new silicone mold without waiting for metal tooling. Mechanical Parts Machining gives you predictable changes, quick turnarounds, and controlled risk - ideal for teams working toward design freeze.

What You Gain, Where It Works, And How To Start

When careful machining meets vacuum casting, you get speed with repeatability. Most parts need minimal finishing. If the brand or use case calls for more, we can paint, polish, or add textures to elevate the look and feel. This route is effective for electronics housings, interior automotive trims, and medical device covers where form, fit, and function all matter.

✅ Typical Use Cases

• Pilot runs needing 10–50 units that look and behave like molded parts

• Design validation of snap-fits, gaskets, optical windows, and living hinges

• User trials demanding consistent parts for multiple test groups

• Bridge production while hard tooling is being prepared

✅ Measurable Value

Mechanical Parts Machining increases part-to-part consistency within each silicone mold's life. It protects small features, reduces polishing time, and tightens cosmetic outcomes. Because each mold usually yields 15–25 parts, a better master extends usable output and stabilizes quality across the batch. That translates into fewer scrap cycles, cleaner assemblies, and a shorter launch timeline.

✅ Our Streamlined Process

• Discovery & DFM: Share your CAD, target resin behavior, and quantities. We flag risks early.

• Machined Master: We cut for tolerance, texture, and moldability - not just appearance.

• Silicone Mold Build: The mold records the master's geometry with high fidelity.

• Vacuum Casting Run: Under vacuum, resin fills evenly for smooth, accurate parts.

• Finish & Inspect: Parts arrive inspection-ready for labs, reviews, or pilots.

✅ Practical Tips To Maximize Results

- Keep walls uniform where possible; large thickness swings invite sink and warp.

- Add draft to ease demolding and extend mold life.

- Specify critical dimensions clearly; let secondary faces float within functional limits.

- For clear parts, request a polished master and plan for protective handling.

Why Teams Choose GD Prototyping

You need dependable speed, not just speed. Our shop links experienced programmers, skilled machinists, and casting specialists under one roof. That tight loop keeps intent intact - no gaps between design, machining, and molding. It also means we can pivot quickly when tests reveal a needed tweak.

Call To Action

Bring us your next prototype or pilot build. Send the CAD, target resin (ABS-like, PC-like, or rubber-like), and quantity range. GD Prototyping will recommend the right Mechanical Parts Machining strategy and vacuum casting plan, then deliver precise plastic parts without the drag of hard tooling. Let's turn your concept into production-like reality - on time and with confidence.