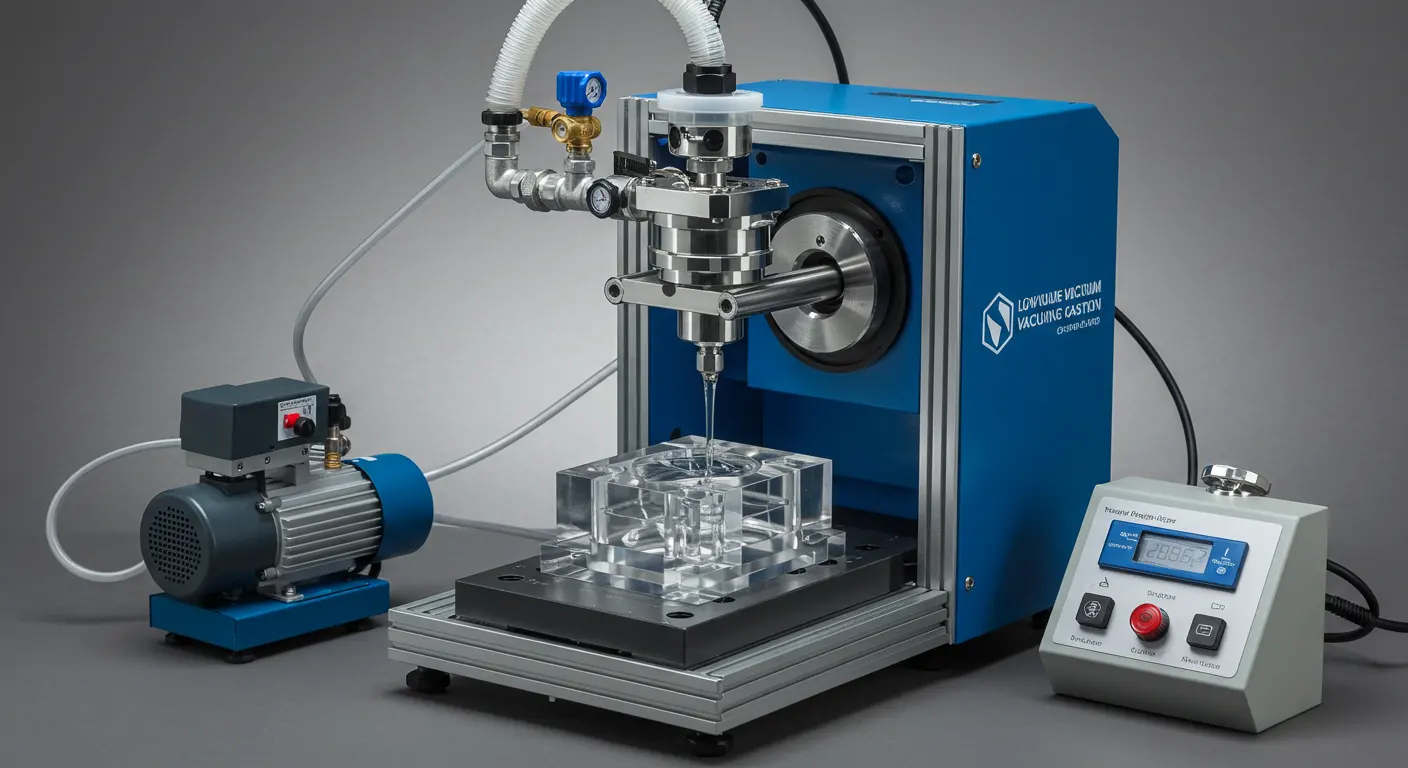

Low Volume Vacuum Casting | Prototype & Small Batch Production

What is Low Volume Vacuum Casting?

- LVVC is a fast process of manufacturing small lots of urethane plastic parts or practical prototypes. It can be made by developing a master model (usually by CNC machining or 3D printing), and silicone is then poured over the model and allowed to cure. After the mold has been cured, urethane resin is then filled into the mold under vacuum so as to eradicate the air bubbles, making the use of urethane resin highly accurate and with high-quality surface finishes.

- The vacuum chamber molding production is most suitable for small-volume vacuum casting processes in which manufacturers need 10 to 100 pieces. It gives the flexibility of RTV mold process with the possibility of replicating intricate geometries and ABS-type materials, rubber-type materials, or transparent resin casting with fine detailing and dimensional accuracy.

Vacuum Casting Process: An Overview

Let's consider the operation of vacuum casting of low-volume production- a technique very popular in prototype production and testing product designs.

- Master Model Creation

This starts with the creation of a master model, typically created through CNC machining, or additive manufacturing substitutes, like 3D printing. The model is an expression of the geometry and surface finish of the last part.

- Silicone Mold Making

A casting box is placed over the master model, and it is enclosed by liquid silicone rubber. After being cured, the mold is cut open very carefully so as to take out the master.

- Preparation and Casting of Resin

Urethane resin, or any other engineering-grade resin, is combined and poured into the silicone mold under a vacuum chamber. The move is used to eliminate the trapped air and give it a perfect finish.

- Curing and Demolding

The cast part is then taken out of the mold after the process of curing (which is normally performed in a heating oven). The silicone moulds have a capacity of 15-25 parts per degradation.

- Finishing and Inspection

Product design verification and functional testing Product design verification and functional testing are performed on the final cast component by surface treatment, painting, or texturing.

What is the Advantage of Vacuum Casting with Small Batches?

Vacuum casting is an ideal option for short-run manufacturing or low-volume production in businesses where start-ups are concerned. It is cost-effective, fast, and flexible - best suited for concept models, functional prototyping, or end-use components. Some key benefits include:

- Economical Prototyping: No need to have the costly steel molds.

- High Accuracy Casting: Perfect for the replication of molds.

- High-Speed Manufacture: The manufacturing cycles are rapid, normally taking days.

- Flexible Design Testing: Parts are easily modified or redesigned without being costly.

- Smooth Finish: Finishes are near infrared injection-molded.

- Low Tooling Cost Process: This is appropriate when it comes to making bridges before full-scale production.

Substances in Vacuum Casting

Vacuum casting is compatible with a broad range of polyurethane resins and RTV silicone molds and is therefore varied in its multiple applications. Common materials include:

- ABS-Type Material - Rigid structural components.

- Rubber-Like Materials - Of flexible elements.

- Clear Resin Casting - To use on clear prototypes.

- Heat-Resistant Materials - To be tested functionally.

- Urethane Resin Casting - General-purpose prototypes.

These resin-based casting solutions are known to make the final parts to achieve the required mechanical properties, dimensional accuracy, and aesthetic quality needed by industries such as the automotive prototyping industry, consumer electronics, and medical devices.

Vacuum Casting Uses

Low-volume vacuum casting is popular in industry equipment components, modelling of aerospace components, and the manufacture of custom components. We can take a few most advantageous industries:

- Automotive Prototyping

This process is ideal when using in dashboard components, grills, and lighting prototypes, as in these cases, the design engineers are able to test fit and performance before production.

- Electronic Manufacturing for Consumers

Vacuum casting is used to test the usefulness of new designs perfectly in enclosures, button panels, and housings.

- Medical Device Prototyping

It uses biocompatible material options to test ergonomic design, as well as proof-of-concept models.

- Aerospace Component Modeling

Supports lightweight, durable parts that are appropriate for high precision.

- Industrial Machinery and Open Source

Small-scale manufacturing of startups also has the advantage of low cost, bespoke prototype manufacture without having to purchase large-scale equipment.

Advantages of Vacuum Casting Over Injection Molding

Comparing vacuum casting and injection molding, it is possible to say that the former is much more efficient in terms of low-volume production. Injection molding can be perfect when it comes to large-scale runs, but it requires high costs of tooling and a lengthy setup time. Instead, vacuum casting:

- Has lower startup costs

- Offers faster turnaround

- Allows design flexibility

- Multi-material run.

Therefore, prototyping by vacuum casting is still a demanded component of the rapid prototyping technology.

Why Do Business with GD Prototypes?

The selection of the correct rapid vacuum casting manufacturer is essential in getting precision, quality, and delivery in good time. We pride ourselves on being a reliable low volume vacuum casting supplier at GD Prototypes, which provides:

- Swedester void vacuum casting service.

- Prototype testing, Vacuum casting in the short run.

- A fast product development firm that is international.

Vacuum Casting Future in Product Development

- With the development of rapid prototyping technology, vacuum casting remains one of the complementary technologies to 3D printing and CNC machining, and serves as a bridge manufacturing technology to designers and engineers.

- The combination of material property testing, manufacturing simulation, and product design verification has allowed the company to proceed with its concept to production more than ever before. The precision molding technology, the resin duplication process, and the tailor-made prototype manufacture all combine to make sure that the vacuum casting process will always be a necessity in the future of low-volume manufacturing.

Conclusion

In recap, low-volume vacuum casting is an affordable, versatile, and quality product to meet the manufacturing requirements of contemporary times. This technique is unmatched in speed, detail, and cost, whether it is to house a consumer product, automotive component, or a medical prototype. In case you are in need of professional vacuum casting, GD Prototyping will be your preferred business partner. From small batch molding to fast prototyping manufacturing, we provide tailor-made solutions that match your product objectives.