What Makes Low-Volume 3D Printing Production So Cost-Effective?

Why is Low-Volume 3D Printing Production so cost-effective? The answer isn't just "no tooling." It's a mix of lean setup, fast revisions, and smarter material use. You pay for parts, not idle molds. You iterate in days, not weeks. Complex geometry no longer adds pain or price. Risk drops because inventory stays light. Cash flow improves because you scale only when demand is real. And quality holds thanks to precise, repeatable processes. But there's a hidden lever most teams miss - one that can cut launch costs even further. Ready to see where the real savings hide?

Why Low-Volume 3D Printing Production Lowers Total Cost

Traditional methods ask you to buy certainty up front: pay for molds, fixtures, and long setups before you know real demand. That model breaks when you only need a few dozen or a few hundred parts. With Low-Volume 3D Printing Production, you bypass tooling. You pay for parts, not speculative capital. For short runs and pilot builds, that single change removes the biggest cost line item.

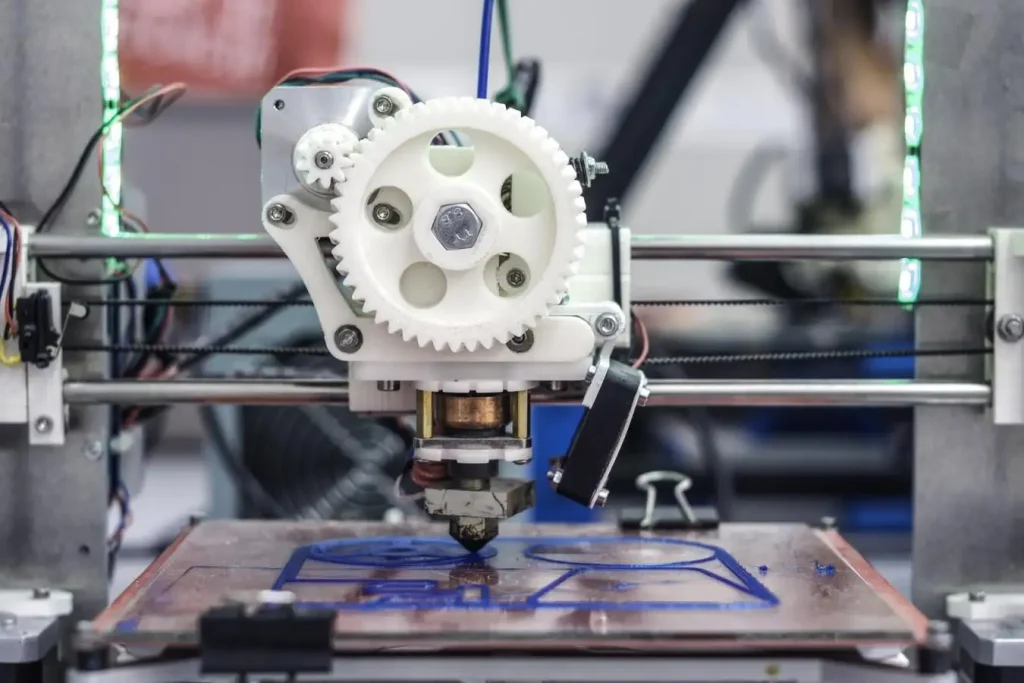

At GD Prototyping, we run SLA, SLS, MJF, and DMLS across plastics and metals. This mix matters. We can match process to intent - cosmetic prototypes, functional nylon housings, or dense metal brackets - without forcing one technology to do everything. Complex internal channels, lattices, and consolidated features carry little to no cost penalty, so you trim assemblies and labor. That is direct savings compared with machining or molding, which often need multiple setups, supports, or multi-part assemblies to reach the same geometry.

✅ Cost Drivers At A Glance

- No Tooling Spend: Skip molds and fixtures for short runs.

- Design Freedom: Combine features and reduce secondary operations.

- Less Waste: Add material where needed; scrap and offcuts shrink.

- Cheap Iteration: Update the CAD, reprint, keep momentum.

Quality costs also drop when accuracy is predictable. On our floor, MJF and SLS routinely hold ±0.3% (lower limit ±0.3 mm) with ~80 μm layers, which is ideal for robust nylon parts that must assemble cleanly. SLA delivers fine cosmetic skins at 50–100 μm for show surfaces and tight features. DMLS builds dense metal components at ~30 μm layers, giving you strength and precision for aerospace, medical, and industrial use. Fewer surprises in metrology means fewer re-spins and less rework.

✅ What The Tech Mix Buys You

- SLA (Resin): Smooth, detailed surfaces for housings, dental models, and fine prototypes.

- SLS / MJF (Nylon): Durable, heat-resistant parts with complex internal geometry for functional prototypes and end-use small batches.

- DMLS (Metal): Stainless steel, aluminum, and titanium parts that are dense and strong for mission-critical applications.

From Prototype To Pilot - Speed Without Compromise

Speed is not just about calendar days. It is about the cost of waiting: idle engineers, missed demo windows, and delayed validation. Our Low-Volume 3D Printing Production workflow compresses cycle time from CAD to parts, so you move from concept to decision without long pauses.

We keep machines, materials, inspection, and finishing in one place to reduce queues and handoffs. For many plastics, parts are ready in 24–48 hours, which fits agile sprints and fast customer feedback. Standard production windows are predictable: SLA, SLS, and MJF typically ship from about 3 business days, while DMLS metals usually start at around 7 business days depending on complexity and volume. When schedules are reliable, build reviews, fixture planning, and field tests stay on track.

Speed also shows up in how quickly you can revise. Need a thicker boss, a new thread, or a different vent path? In a printed workflow, change is a file update, not a tooling change notice. You adjust, reprint, and keep testing - often within the same week.

- Finishing For Production Looks And Performance

Short runs often face a tough brief: they must look like production, feel like production, and survive handling. We offer finishing options you can mix and match:

- Standard Finish for clean, consistent parts that assemble easily.

- Painting / Dyeing / Clear Coating to lock in color, gloss, and clarity for customer-facing pieces.

- Polishing & Vapor Smoothing to improve surface feel and reduce porosity on suitable plastics.

- Electroplating & Heat Treatment to enhance appearance, conductivity, or strength on metals.

Every part ships with inspection photos and reports, so quality data travels with your hardware and your team can trace, compare, and learn from each iteration.

When To Choose Low-Volume 3D Printing Production - And How We Help

Low-Volume 3D Printing Production is the right tool when demand is unclear, geometry is complex, or timelines are tight. It is ideal for new product intro, engineering validation, and revenue-ready bridge builds before large-scale tooling makes sense. If your design calls for internal channels, graded lattice, or part consolidation, printing is often the only practical way to hit function without ballooning cost.

In early concept phases, you validate form, fit, and function in days - so the team decides with parts in hand, not guesswork. In pilot production, you deliver saleable parts without waiting for steel. And when procurement asks about risk, you have a supply chain that scales up or down without stranded inventory.

✅ Common Use Cases

• Pilot Builds & Bridge Production: Ship units while tooling is under review.

• Service & Aftermarket: Print spares on demand; avoid carrying slow-moving stock.

• Customization: Batch-size-one variants without setup fees or line changeovers.

• Regulated Prototypes: Functional nylon or metal parts for repeatable testing.

At GD Prototyping, we act as your manufacturing partner, not just a print shop. Send us your intent and constraints - target weight, environment, assembly plan - and we'll steer you to the right process and material. We flag geometry tweaks that reduce supports, improve orientation, and shorten finishing time. The result is a smoother path from CAD to "ready to ship."

• Wide Material Selection: Plastics and metals tuned to real-world use.

• High Precision: Dimensional control suitable for fixtures and assemblies.

• Reliable Delivery: Flexible scaling with consistent quality checks.

Call To Action: If your next short run needs speed, predictable cost, and strong aesthetics, let's talk. Share your CAD for a fast manufacturability check and quote. We'll recommend the best route for Low-Volume 3D Printing Production - SLA, SLS, MJF, or DMLS - and get parts moving quickly, without locking you into tooling you may not need.