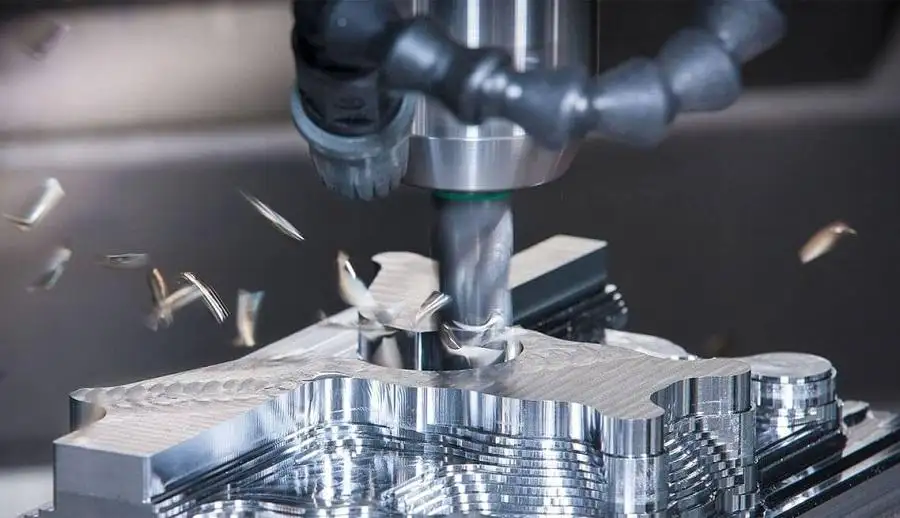

How Customized CNC Machining Solves Complex Design Challenges

Customized CNC Machining turns difficult ideas into real parts - fast. Tight tolerances. Sharp edges. Tricky blends. We handle them without drama. As a world-class, certified contract manufacturer, we focus on rapid prototyping, low-volume, high-complexity, and highly flexible production across precision machining, assemblies, and integrated systems. No hard tooling. No guesswork. Just clean geometry and consistent results from prototype to short-run builds. But here's the question that matters: what happens when walls get thin, angles compound, and surface finish cannot slip? In the next section, we reveal how we keep accuracy - and your schedule - under control, even when designs push the limits.

Turning Difficult Designs Into Manufacturable Parts

Complexity often hides in the gap between a beautiful CAD model and a stable machining plan. Thin ribs can resonate, deep pockets can force awkward tool reach, and multi-surface blends can stack tolerances in ways that only appear during inspection. Customized CNC Machining addresses these pain points by adapting the process to the part rather than forcing the part to fit a generic process.

At GD Prototyping, we combine 3-axis, 3+2-axis, and full simultaneous 5-axis milling to reduce setups, preserve datums, and protect feature relationships. Simultaneous 5-axis lets us cut difficult angles in one continuous motion, improving surface integrity and dimensional accuracy. For rotational components - housings, shafts, and parts with axial and radial features - CNC turning brings the concentricity and finish quality that tight assemblies demand. The outcome is consistent repeatability from first article through short-run builds and into end-use production.

Our work typically begins with practical design-for-manufacture (DFM) feedback. Minor fillet changes, relief features for tool exit, or adjusted wall thicknesses can remove risk without altering functional intent. Once validated, a single digital program becomes your golden thread - ideal for rapid prototyping CNC services and low-volume precision machining services where reliability and speed matter most.

Precision You Can Measure, Surfaces You Can Trust

Precision is where many programs stumble. We maintain tight tolerances of ±0.05 mm (when specified) and achieve surface roughness down to Ra 0.2 μm on critical faces. General tolerances follow DIN 2768-1 - fine for metals and medium for plastics - so acceptance criteria are clear from the outset. Smart toolpath strategies reduce witness marks and achieve uniform finishes; when the as-machined look isn't appropriate, we offer finishing options that enhance performance and aesthetics without compromising dimensional targets.

Material and finish choices are integral to function and downstream assembly. Customized CNC Machining at GD Prototyping supports a broad palette of metals and plastics, along with practical post-processes that improve wear, corrosion resistance, and cosmetic appeal. Because our programs are fully digital and revision-controlled, re-runs remain consistent even when your design iterates. That agility shortens verification loops, reduces scrap, and preserves budgets.

- What This Looks Like In Practice

• Fewer Setups, Better Datums: 3+2 indexing and simultaneous 5-axis maintain tight relationships across faces and features

• Cleaner Surfaces: Uniform tool engagement and high-speed strategies minimize cusp height and rework

• Predictable Outcomes: Stable workholding and verified tool libraries protect both tolerances and schedule

Capacity, Responsiveness, And The Details That De-Risk Launch

Machines alone don't solve complexity - coordination does. Our project managers orchestrate people, processes, and tooling so you get parts when you need them, at the quality you specified. Expect one-on-one support with responses within 12 hours. Inside our facility, in-house equipment runs 24/7, which is essential for urgent prototypes, engineering builds, or quick-turn production.

Capabilities Snapshot For Customized CNC Machining

- 3-axis, 3+2-axis, and simultaneous 5-axis milling for multi-face features and deep cavities

- CNC turning for precise shafts, bores, grooves, flats, and threaded geometry

- Diverse metals and plastics, plus functional finishes and clear tolerance guidance

- From one piece to 1,000+ pcs - no hard tooling investment required

These capabilities let us machine complex, multi-structure components efficiently. Simultaneous 5-axis cuts compound angles in one pass, 3+2 locks in stable orientations for high accuracy, and classic 3-axis remains the efficient choice for prismatic elements. In combination, we protect stack-ups, avoid tolerance creep, and keep cycle times competitive.

From Prototype To Production, Without Skipping A Beat

You need more than a great part - you need a reliable path to market. Customized CNC Machining minimizes changeovers and avoids the delay and cost of hard molds. With a single validated program, we scale smoothly from prototypes to pilot lots and into end-use runs while maintaining traceable quality documentation. That's critical when demand is uncertain, product revisions are frequent, or supply chains are under stress.

- Rapid Prototyping: Functional, test-ready components that mirror final design intent in look and performance

- Low-Volume Production: Bridge builds with flexible scaling and consistent reliability

- End-Use Production: Repeatable manufacturing for thousands of precision parts backed by stable process controls

Where Customers See The Biggest Wins

- Productivity & Efficiency: Machines run continuously; programs are reusable and quickly adaptable to new variants

- High Precision Tolerances: Verified toolpaths and robust fixturing hold critical dimensions across batches

- Flexibility: Fast reprogramming supports late-stage changes without new tooling or long delays

- Speed To Market: Quick turnarounds from an in-house, 24/7 shop reduce lead time and inventory risk

Why Choose GD Prototyping For Your Next Complex Part?

Because we match process to part. Customized CNC Machining isn't a single technique; it's a disciplined approach that unites programming, workholding, tool selection, and inspection around your unique geometry. Our team brings practical DFM support up front, production discipline throughout, and transparent communication at every milestone. You get parts that fit, function, and finish correctly - and a manufacturing partner who helps you make better decisions faster.

Final Words

Ready to turn complex geometry into shippable hardware with fewer surprises? Send your CAD, material, tolerance, and finish requirements to GD Prototyping today. Our engineers will reply within 12 hours with actionable DFM feedback and a fast, no-nonsense quote. Put Customized CNC Machining to work on your next build - and keep your program moving from first article to final delivery.