Custom CNC Machining Services for Prototypes – The Key to Faster, More Accurate Product Development

In today’s fast-paced product development cycle, speed and precision are essential. Whether you are designing a new consumer gadget, a complex aerospace component, or a custom medical device, CNC machining for prototypes offers an unmatched combination of accuracy, flexibility, and efficiency.

At GD Prototyping, we specialize in custom CNC machining services tailored to meet the needs of engineers, designers, and manufacturers worldwide. Our advanced capabilities allow us to turn your ideas into functional prototypes—fast, accurately, and with full attention to quality.

What Is CNC Machining for Prototypes?

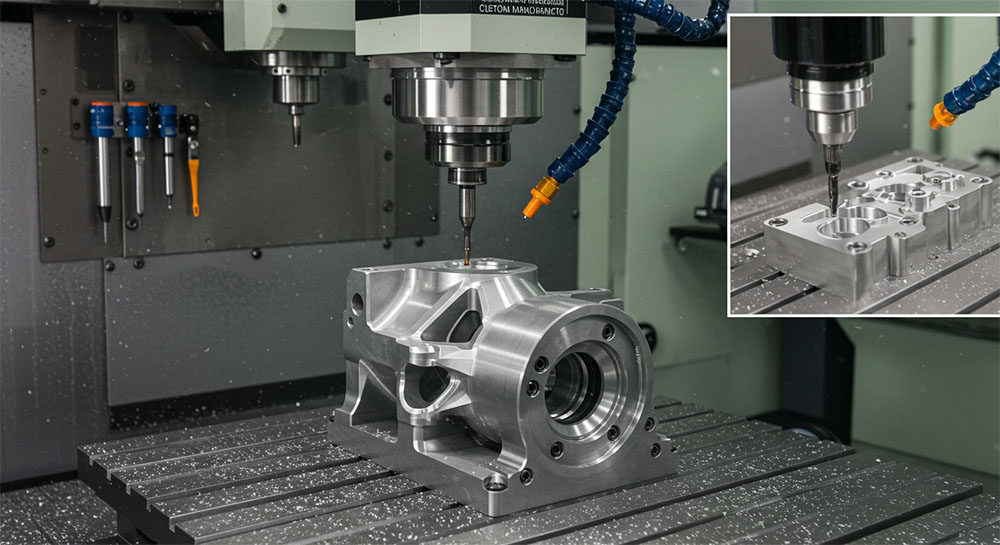

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where automated machine tools remove material from a solid block (metal, plastic, or composite) to create a precise final shape.

In prototype manufacturing, CNC machining is widely used because it offers:

- High dimensional accuracy – tight tolerances as small as ±0.005 mm

- Material flexibility – works with aluminum, steel, titanium, ABS, PEEK, acrylic, and more

- Fast turnaround – from CAD design to a finished part in days

- Scalability – suitable for one-off prototypes or low-volume production runs

Why Custom CNC Machining Is Ideal for Prototyping

- Precision and Repeatability

When creating prototypes, especially for industries like aerospace or medical devices, exact dimensions are critical. CNC machines ensure every part is produced with consistent precision, eliminating errors that could delay product testing. - Wide Material Selection

CNC machining supports almost any machinable material—metals, plastics, and composites—making it ideal for functional testing where the prototype must mimic the final product’s properties. - Design Flexibility

Engineers can quickly modify CAD files and produce updated prototypes without the need for costly tooling changes. - Short Lead Times

Rapid CNC prototyping means you can test, iterate, and finalize designs faster—reducing time-to-market and improving competitiveness.

Our Custom CNC Machining Capabilities

At [Your Company Name], we provide full-service custom CNC prototyping solutions, including:

- 3-Axis and 5-Axis CNC Milling – for complex geometries and intricate surfaces

- CNC Turning (Lathe Work) – ideal for cylindrical parts and high-precision shafts

- Multi-Material Machining – metals (aluminum, brass, stainless steel, titanium), plastics (ABS, POM, nylon, PEEK), and more

- Rapid Prototyping – same-day or next-day machining for urgent projects

- Low-Volume Production – bridge manufacturing from prototype to full-scale production

- Surface Finishing Options – anodizing, powder coating, polishing, bead blasting, painting, and laser engraving

Industries That Benefit from CNC Prototype Services

Our custom CNC machining for prototypes supports a wide range of industries, including:

- Aerospace & Defense – lightweight yet strong metal components with tight tolerances

- Automotive – prototype engine parts, custom dashboards, and performance upgrades

- Medical Devices – surgical tools, prosthetic components, and diagnostic equipment housings

- Electronics – precision enclosures, heat sinks, and mounting brackets

- Industrial Machinery – gears, housings, and test fixtures

Step-by-Step CNC Prototyping Process

- Design & Engineering Review – We evaluate your CAD files for manufacturability

- Material Selection – Choose the best material for your application and testing needs

- CNC Programming – Our engineers translate designs into precise machining instructions

- Machining – Automated CNC mills and lathes cut, drill, and shape the part

- Quality Inspection – Every part undergoes rigorous measurement and testing

- Surface Finishing – Enhancing aesthetics and durability based on your requirements

- Delivery – Fast, secure shipping to your location—whether local or international

CNC Machining Services in china

If you’re looking for custom CNC machining services in china, our team is strategically positioned to deliver both speed and reliability. With state-of-the-art facilities and global logistics support, we serve clients in major manufacturing hubs such as [New York, Los Angeles, London, Sydney, Singapore, etc.].

By choosing a local or regionally-optimized CNC provider, you benefit from:

- Faster shipping and reduced lead times

- Local engineering support for easier communication

- Compliance with regional standards and certifications

When you search for terms like:

- Custom CNC machining services

- CNC prototyping company in [City]

- Precision CNC manufacturing for prototypes

- Rapid CNC machining near me

—you’ll find GD Prototyping ranking among the top results because we invest in cutting-edge manufacturing capabilities and transparent, customer-focused service.

Why Choose [Your Company Name] for CNC Prototyping?

- Over 15 years of CNC machining experience

- ISO-certified quality control for consistent excellence

- Dedicated project managers for clear communication and smooth workflow

- Competitive pricing without compromising quality

- Global reach with on-time delivery

Get a Free CNC Machining Quote Today

Whether you need a single prototype or a small production run, our custom CNC machining services can help you achieve your goals—fast and efficiently.

📩 Contact us today with your CAD files and specifications for a free, no-obligation quote. Let’s turn your design into a high-quality, functional prototype that’s ready for testing and market launch.