CNC Turning Prototyping Services | Custom Precision CNC Turned Parts

What is CNC Turning Prototyping?

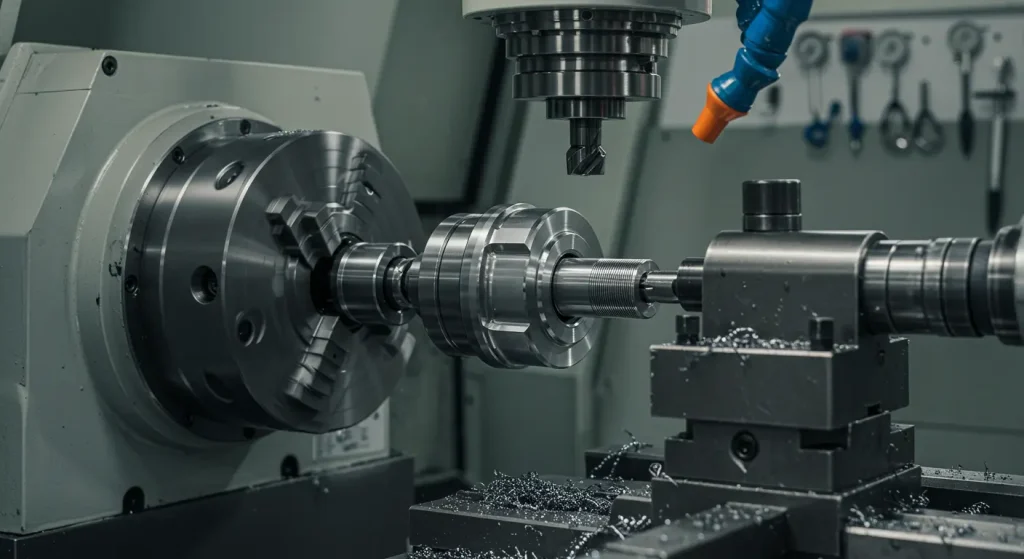

- CNC turning prototyping is a subtractive type of manufacturing that employs the CNC lathe machine to cut through the raw material at a very high speed by cutting away the undesired layers of the material using cutting tools. It can be programmed and controlled via CNC programming and control to achieve high-precision tolerance, dimensional accuracy, and repeatability, and is ideal for prototype part validation and functional prototype testing.

- CNC turning, in contrast to manual turning, has CAD/CAM design integration, which means that 3D digital models may be converted directly to machined prototype parts. With the 3-axis and 5-axis CNC turning, even the most complicated structures can be produced with perfection in finishing the surface and polishing.

CNC Turning Prototyping: The Art of Standing Still and Light Speed Product Creation

In this rapidly changing manufacturing environment of modern times, CNC turning prototyping has emerged as one of the cornerstone technologies that has amalgamated precision machining technology, fast manufacturing services, and digital innovation into a single powerful process. Whenever companies require robust, high-quality, and precise prototypes resembling the final product, CNC turning prototype services are the provider of choice.

- In aerospace CNC prototyping, in medical device CNC turning parts, in testing automotive turned components, or in other types of production, this process will provide the speed, accuracy, and material flexibility needed in the modern day.

- At GD Prototypes, our main business is to bring ideas into reality by creating custom CNC turning prototypes, which are characterized by high machining accuracy, surface finishing, and tight tolerance machining for clients in different industries.

Process of CNC Turning

The CNC turning process has a sequence of highly automated processes that aim to make it accurate and repeatable.

- CAD/CAM Design Creation - Designing the prototype is done by an engineer using CAD software, and CAM systems are used to create tool paths.

- Workpiece Set Up - Depending on the chosen material (aluminum, stainless steel, titanium, or plastic), it is mounted on the CNC lathe machine.

- Turning and Facing - With the help of live tooling, boring and facing, the lathe will remove the unwanted material.

- Tool Path Optimization - The tool paths are optimized to minimize the cycle time and improve finish quality.

- CNC Programming and Control - The machine uses programmed instructions to make high-precision prototypes.

- Surface Finishing and Polishing - This step is the last one that is taken to achieve perfect production of prototypes with smooth textures and correct profiles.

This is an end-to-end procedure that renders CNC turned parts prototyping ideal in situations where there is low volume production, prototype to production services, and concept to production solutions.

Optimal CNC Turning Prototypes Materials

The choice of materials is important in the realization of functionality and the finish desired. Our CNC metal turning prototypes and plastic CNC turning are available in a broad choice of engineering-grade materials, such as:

- Aluminum Turning Prototypes - Lightweight, not corrosion-resistant, and machinable.

- Stainless Steel Machining - Hard, tough, and suitable in high-stress applications.

- Turning - Covers electrical and ornamental parts.

- Titanium CNC Prototypes - Strength to weight ratio- High strength to weight ratio used in aerospace or medical applications.

- Plastic and Polymer Machining - Ideal when the prototype is low-weight and low-cost.

- Composite Prototype Machining - Of special industrial and electronic parts.

Every material will be subject to quality control checks, automated measurement, and surface treatment to achieve material part repeatability.

Benefits of CNC Turning as a Prototype Manufacturing

- Incomparable Accuracy and Tolerance

Tight tolerance machining to the micron dimension is provided through CNC turning prototyping and guarantees that the dimensional accuracy is comparable to that of final production.

- Rapid Turnaround

Instead of taking days to CNC turn your design, the rapid prototyping of CNC turned products, your product development cycle, and market testing is shortened to hours.

- Design Flexibility

With multi-axis turning and integration of CAD/CAM, even complicated geometries can be made seamlessly, which is ideal when making custom CNC turning prototypes.

- Material Versatility

Since metal alloy prototyping, CNC turning is an excellent complement to prototyping with plastic machining, which has a broad material variety that can be used in both prototype and functional end-use applications.

- Scalability

After the prototype has been tested, the same system can be increased to low-volume production or contract manufacturing, with continuity from the prototype to the final product.

CNC Turning Prototype Tolerance and Precision

- The tolerance and accuracy are the core of any precision CNC turning prototyping work. In GD Prototypes, our tolerances are as fine as +-0.005 mm, based on CNC machining and Swiss turning centers, plus multi-spindle lathes that are ISO-certified.

- Our automated systems, combined with real-time monitoring, ensure that the production of prototypes is without defects- important in such industries as aerospace, medical, and electronics, whereby performance is determined by precision.

Role of CNC Turning Prototyping in Aiding Fast Product Design

- CNC prototyping is the solution in a world where innovation is the driver. Digital manufacturing technology and Industry 4.0 CNC technology allow faster prototyping, design experimentation, and a smooth transition into production.

- This type of fast product development cycle saves time-to-market and provides engineering-grade models that match the precise specifications. It particularly proves useful in the cases of industrial machinery prototyping, automotive turned parts, and electronic components that need the services of high-precision machining.

Industrial Applications

Our CNC prototyping experience is in diverse industries:

- Aerospace CNC turning prototypes - For low-weight, highly engineered parts.

- Engine, suspension, and custom interior parts prototyping - Auto turned parts.

- Nanotechnology - CNC turning medical devices - Biocompatibility and precision of dimensions.

- Heavy-duty manufacturing systems, parts prototyping - Industrial equipment.

- Prototyping of electronics, CNC machining - Compact housings and heat sinks.

All the parts are subjected to quality control inspection, which makes them durable and functional.

Why Choose GD Prototypes?

- CNC Machining Plants certified by ISO.

- State-of-the-art 3-axis and 5-axis CNC Lathe Machines.

- Individual Engineering Solutions for each project.

- Fast Turnaround Machining of urgent orders.

- Cheap CNC Prototyping without cutting corners.

Conclusion

CNC turning prototyping is the key to mediating between the creative and the innovative in the current competitive world of manufacturing. Integrating the technology of precision machining, quickly developing tools, and designing specific CNC applications allows a quicker cycle of designing, less waste, and an improved level of accuracy. Our mission at GD Prototyping is quite basic: we help you to transform your creative vision into working prototypes that lead to success.