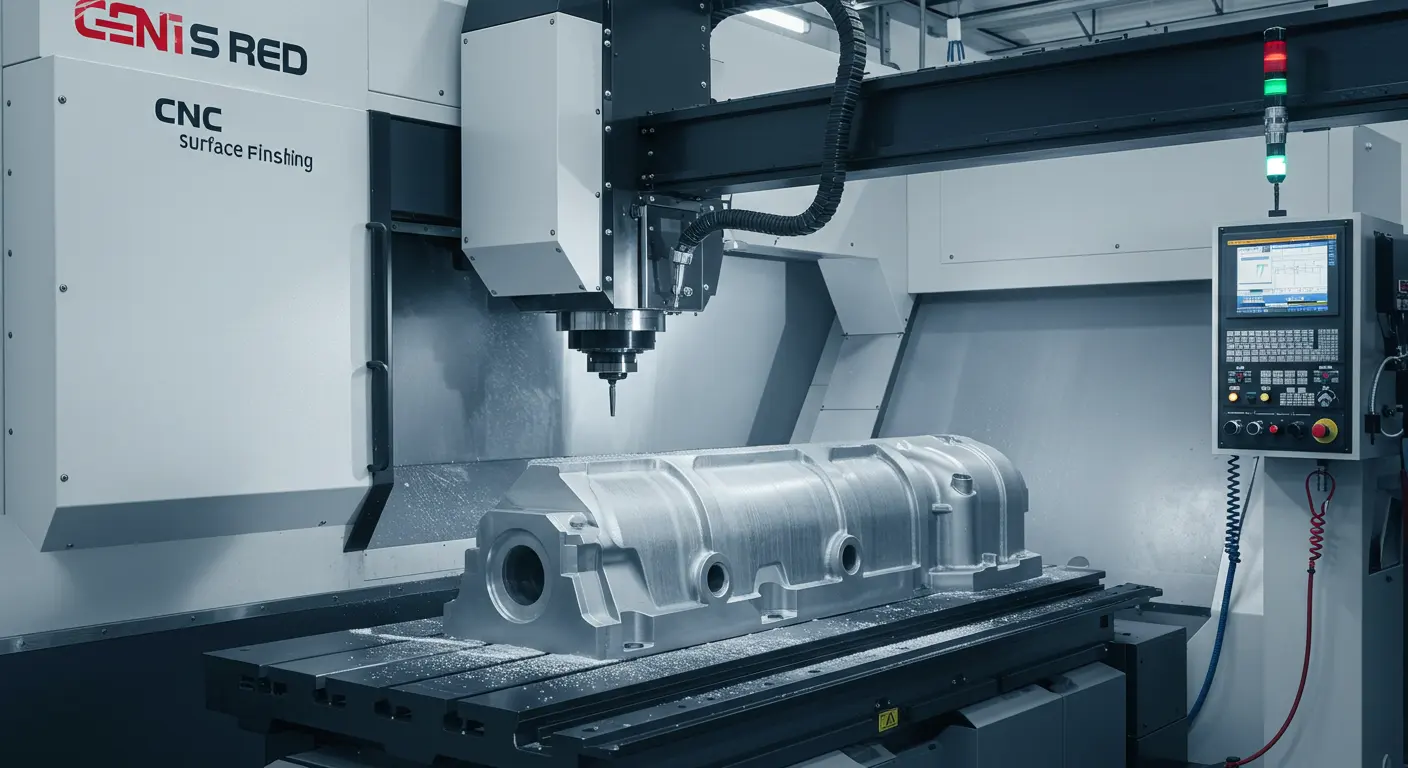

CNC Surface Finishing | Precision CNC Polishing & Surface Treatment

What is QCNC Surface Finishing?

Surface finishing in CNC machining is used to refers to the finishing applied to the surface of a part by a secondary machining process after the primary machining process to improve the surface roughness, texture, and aesthetic appearance of the part. The finish determines the smoothness, reflective, or functional nature that a surface will have. Since CNC surface polishing, bead blasting, anodizing, and chemical polishing, each process has its own peculiarities that enhance corrosiveness and wear characteristics, as well as coating bonding.

- A clear CNC part surface finish not only looks much better but also helps to increase machining surface quality, decrease friction on moving parts, and prepare surfaces to be subjected to other treatments, including painting, powder coating, or electroplating.

- In precise engineering, a surface finish may be quantified with values of Ra (average roughness), Rz, or Rt, which is the amount of difference present between pits and heights on the surface. High-performance applications require more tolerance of surface finish in CNC machining (normally between 0.2-1.6 mm Ra) to ensure smoothness and stability.

CNC Surface Finishing: Accuracy, Excellence, and Effectiveness

- CNC surface finishing is an essential factor in the contemporary world of advanced production, as it is considered to be the determinant of the quality, durability, and beauty of machined components. It is not merely the issue of forming a part, but that of refining the machined texture of the surface, dimensional precision, and serviceability. Be it aerospace parts, automotive parts, or medical devices, once the optimum CNC machining surface finish has been obtained, making precision turn into perfection is the last bit of the process.

- We are GD Prototypes, which specializes in CNC surface finishing services with ultra-high precision and micron-level tolerances, and a mirror-like quality surface. The sophisticated CNC surface treatment procedures make sure that not only will all components be technically adequate, but also perform beyond the standards in terms of performance, looks, and durability.

Technical Benefits of CNC Finishing Surfaces at GD Prototypes

In GD Prototypes, CNC (Computer Numerical Control) processing technology is used to produce precision metal parts, and the quality and repeatability cannot be matched. The main benefits are as follows:

- Extreme High Accuracy and Stability

The accuracy of our CNC machining finish is at the micron level (+-0.005mm), except for the most complicated geometries, which are still far within the dimensional tolerances. We ensure that all surfaces control the surface texture and ISO surface finish requirements through high-level computer-controlled tool paths.

Be it the joints of the robots, aerospace blades, or medical surgical equipment, our CNC precision finishing methods guarantee motion, wear-resistance, and reliability over time.

- Complex Geometric Structure Processing

Our multi-axis CNC machines (5-axis/6-axis) can perform complicated geometric operations addressing deep grooves, curved surfaces, thin walls, and micro-channels, which their traditional manufacturing counterparts cannot accomplish. Such versatility has allowed GD Prototypes to become a reliable provider of CNC finishing medical devices, aerospace components, and custom prototype surface finishing.

The surface consistency, even on more complex shapes, is what guarantees a better look and mechanical performance of machined parts.

CNC Surface Finishing Processes

CNC machining processes depend on the material used, its appearance, and functional use; thus, the surface finishing methods differ. The following are a few of the commonly utilized techniques at GD Prototypes:

- Surface Finish: CNC, Anodizing

A nodding of metal surfaces is the main process that is applied to aluminum to finish the surface. It improves corrosion resistance, wear resistance, and color stability. We produce surfaces that are hard in nature and whose hardness surpasses 60 HRC, which is perfect in aerospace and automotive applications.

- Bead Blasting CNC Finish

Bead blasting gives the texture of a matte one by firing glass beads of approximately 0.05mm. It eliminates markings left by machining, smoothes the surface irregularities, and improves the surface finishing of custom CNC parts.

- Sandblasting CNC Machining

In parts that need a more aggressive cleaning or brush surface finish, sandblasting provides a smooth texture and conditions the part to receive powder coating or an adhesive paint.

- Mirror Surface Finish CNC

Mirror surface finish CNC is the answer when aesthetics are combined with precision. Our finishes are reflection-grade via buffing, electropolishing, and using fine abrasives good on medical implants and optical components.

- Polishing CNC Chemicals

It is a non-mechanical technique of finishing in which irregularities on the surface are dissolved by controlled chemical reactions. Ideal in stainless steel, copper, and brass finishes, giving it a high gloss surface and a no oxidation look.

- Surface Finish CNC Electroplating

It is a process that leaves an effect of a thin coating of metal coverage, e.g., chrome, nickel, or gold, onto the machined surface to enhance corrosion resistance, hardness, and conductivity. It is commonly applied in the polishing of electronics enclosures as well as ornamentation.

- Powder Coating CNC Parts

Powder coating provides a decorative and tougher anti-scratch and anti-chemical and may be in many colors and textures.

CNC Surface Finishing Uses in the Industries

The relationship between engineering excellence and product functionality is CNC surface finishing. The overall industries gain in the following manner:

- Surface Finishing Aerospace CNC

Guarantees fatigue resistance and lightweight durability in turbine blades and fuselage frames components, as well as oxidation protection.

- CNC Surface Finishing of Automotive

Offers scratch resistance, low friction, and heat endurance enhancement service to enhance the behavior of engine parts and suspension systems.

- Finishing CNC of Medical Devices

Ensures biocompatibility, mirror polish, and sterility, which are important in the case of implants, surgical instruments, and diagnostic equipment.

- CNC Surface Finish Electronics

Enhances conductivity, aesthetics, and EMI shielding of enclosures, housings, and connectors.

- Custom Prototype CNC Finishing

Provides aesthetics and functional integrity to prototype fast and test a concept.

Why Should GD Prototypes Be Selected as a CNC Surface Finishing?

Our team of engineers provides decades of experience in CNC precision finishing, in addition to the latest technology at GD Prototypes. Our own CNC finishing solutions provide professional CNC polishing and CNC surface treatment of all materials and industries. The main differentiators that we have are:

- Micron level precision + -0.005mm.

- Surface consistency inspection tools that are advanced in machining.

- Surface treatment knowledge is material-specific.

- Quick turnaround/peculiar finishing.

- Prototyping to production support.

We do not produce parts, we make masterpieces, one that portrays precision in engineering and a magnificent look of beauty.

Conclusion

Nowadays, the level of competitiveness in manufacturing requires CNC surface finishing not only to be a cosmetic feature, but also a pillar of performance, longevity, and brand quality. Mirror polishing, hard anodizing, and all finishes have a story behind them of craft and innovation. At GD Prototyping, we will be making sure that no surface is less than perfect. Could you use aerospace-grade finishes, medical-grade finishes, or prototype detailing? Our team can ensure high standards of finish that glistens, literally and technically.