CNC Milling Prototype Services | High-Precision Machining

What is CNC Milling Prototyping?

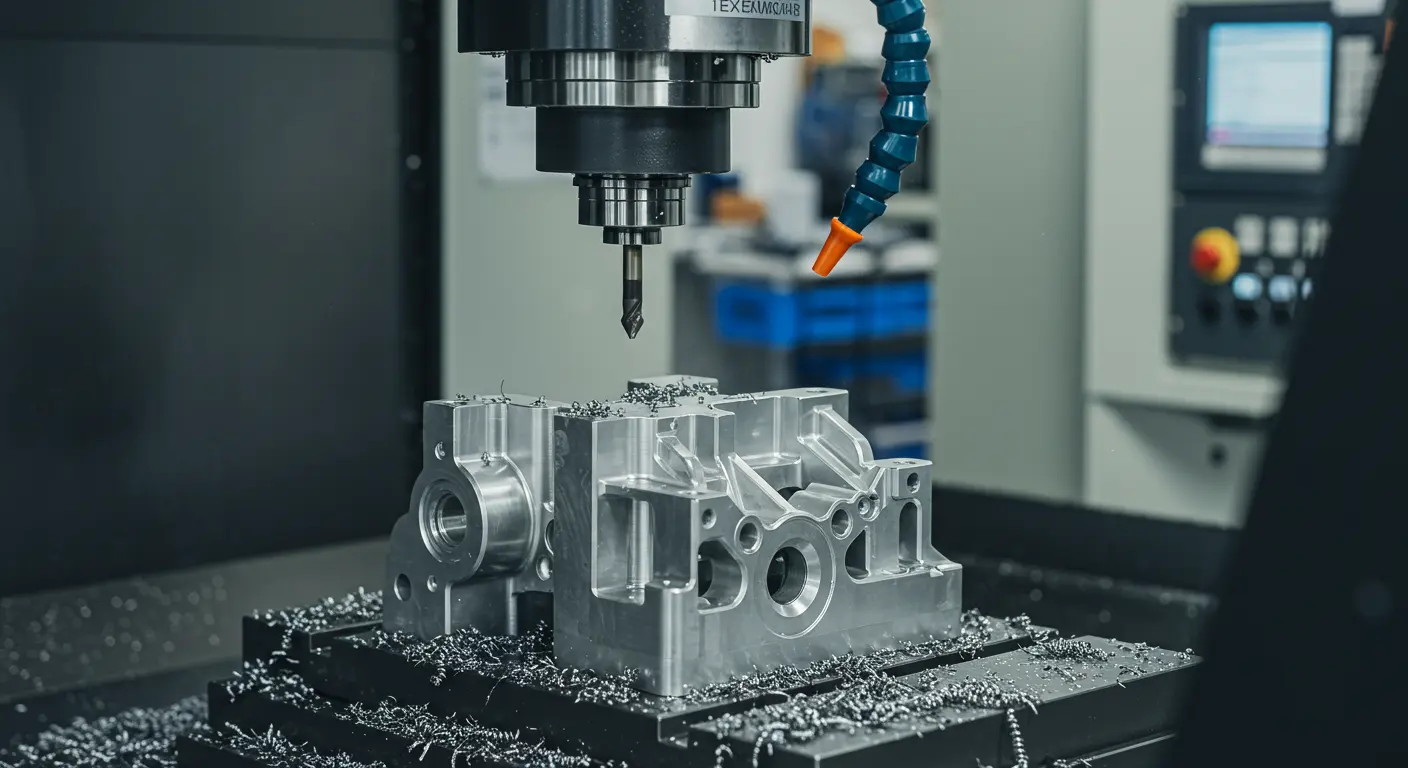

- CNC milling prototyping represents a subtractive type of manufacturing that uses a computer numerical control (CNC) to cut material out of a solid block - known as the workpiece - to form correct part geometry. It is an integration of CAD/CAM design, toolpath optimization, and multi-axis milling technology, which produces precise and complex shapes in an efficient manner.

- Unlike the traditional methods, the CNC milling prototype services will be equipped with 3-axis machining as well as 5-axis machining in order to achieve tight tolerance machining and perfect production of the prototype. This is most applicable in the application of functional prototype tests, low-volume production, and concept to production machining.

CNC Milling Prototypes Services: Innovation, Accuracy, and Reliable Quality

- Success in the fast-moving product development world is a measure of speed, precision, and flexibility. CNC Milling Prototype Services is the sole manufacturing solution that is precise, multifunctional in terms of material utilization, and repetitive. CNC milling offers high precision prototyping, both in developing a concept model or taking it to full-scale production. The prototype will be prototyped in all dimensions, surface finish, and material performance that is identical to that of the final product.

- We are GD Prototypes, a business that engages in the prototype service business, which entails CNC milling and offers the engineers and designers an opportunity to bring the CAD ideas into reality or produce functional and production-ready parts with a precision of the microscopic scale.

The Purpose of the CNC Milling is to Create the Prototype

Prototypes also have a significant role in developing a new product since they are applied to test, prove, and determine the viability of the product. CNC milling gives unbelievable control of size and dimension tolerances that give you repeatable and accurate parts that are within the context of your general design goal.

High Precision and Accuracy

- The accuracy of the current CNC milling machines is within the micron scale (+-0.01mm or even lower). In machining 10 or 1000 parts, the same dimensions, position of holes, and finish of surfaces are identical.

- Finishes to CNC machined surfaces can be down to 0.8mm (Ra) and even less to meet the needs of quality assemblies such as aerospace, automotive, and medical needs.

- They can also be followed by other finishing processes such as polishing, deburring, and electropolishing, which are easily added to enhance the standards of the surface finishing and polishing.

Wide Range of Materials

- The material offered by CNC milling is diverse, with stainless steel, aluminum alloy, copper, carbon steel, titanium alloy, and engineering-grade polymers.

- The diversity enables prototype machining solutions to meet the diverse performance needs - anti-corroboration, lightweight structures, and high-strength uses.

Scalable and Repeatable

In addition to the fact that you are in a hurry to obtain the prototypes of CNC milling, either you require low volume and CNC milling production, the process has ensured that the dimensions are accurate and the process and stability are controlled. All prototypes are inspected, controlled, and tested with the help of automatic control and measuring tools, and other modern metrology devices.

Explaining CNC Milling Prototype Process

The milling process of CNC is a digital-physical process linking the CAD structure to the truth of production. Here's how it works:

Step 1 - CAD/CAM Design Integration

It starts with a CAD model, which defines the geometry of the part. The model is brought into the CAM simulation software, where toolpaths are generated and optimised.

Step 2 - Material Selection

It is made using either aluminum, stainless steel, brass, copper, plastic, or even titanium, depending on the needs of the parts. The materials possess personal machinability and weight strengths.

Step 3 - Toolpath Optimisation and configuration

The system determines optimum milling plans such as face milling, slotting, and contouring, to ensure the removal of the material and quality of the surface is achieved.

Step 4 - Control and CNC Programming

High CNC and programming ensure accurate machining technology and multi-axis movements synchronization, especially 3-axis and 5-axis machining.

Step 5 - Preparation and Milling of Workpiece

The workholding and fixturing process retains the process of machining. With further repetitions of the milling cutter cycle, the material gets cut away, forming the prototype to tight tolerances and a smooth surface texture.

Step 6 - Inspection and Finalization

The dimensional accuracy, the roughness of the surface, and the positioning of holes can be checked with the help of the automated quality inspection tools after the work is done. Other finishing, like anodizing, polishing, painting, or sandblasting, is done as needed.

Types of Revolve Prototyping Services

In GD Prototypes, we provide a great variety of CNC machining of prototypes depending on industry-specific demand:

- 3-Axis CNC Milling Prototype

Applicable to flat parts and simpler contours, 3-axis milling is economical and precise in most machined prototype parts.

- 5-Axis CNC Milling Prototype

In complicated geometries and undercuts, 5-axis machining allows access to tools from many angles, consequently, avoiding the setup time and improving the quality of surface finish.

- CNC Milling Prototype Custom

The prototypes are designed with the CAD model optimization and Design for Manufacturability principles to ensure that the ready components are manufactured.

Merits of CNC Milling Prototypes Services

Rapid Component machining: CAD to component. Quick component machining can occur in days.

- Flexibility of Design: Proper for complicated 3D geometries, multi-axis applications.

- Cost Effectiveness: On-demand machining helps minimize short-run tooling.

- Scalable: It is capable of scaling between prototyping and low-volume production.

- Functional Testing: It is good for product testing and testing validation.

These fast prototyping CNC milling machines find application in concepts to production machining, and hence are significant to such industries as robotics, aerospace, automotive, and electronics.

Conclusion

We have incorporated digital production, modern machining methods, and high-quality control into the industry, and that is why your vision will be a reality, just like the way you have imagined it every time. You will not repent, and we have years of experience on what it is like to operate in GD Prototyping, the company you have trusted over time when you require precision CNC milling prototype services.