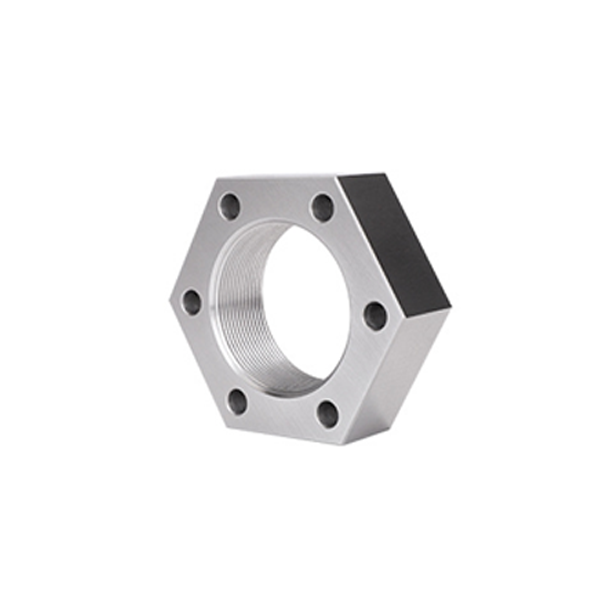

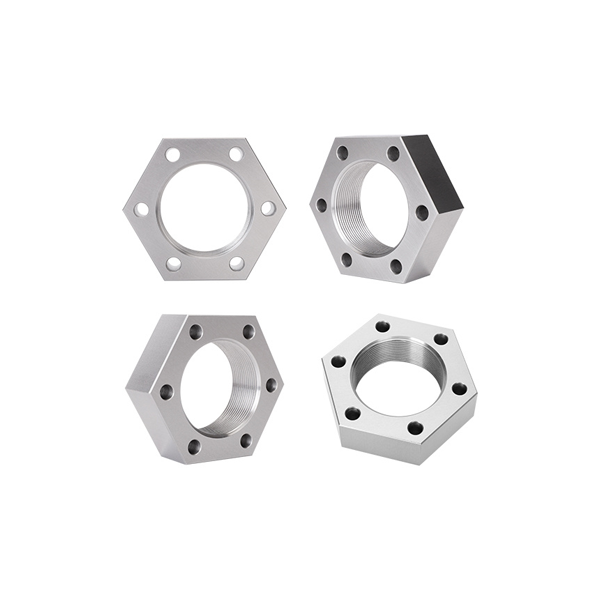

Small Batches

Small batch prototyping bridges the gap between one-off prototypes and full-scale production, offering manufacturers an efficient way to test, validate, and launch new products. It involves producing limited runs of functional parts—often in quantities from a few units up to several hundred—using methods such as CNC machining, vacuum casting, 3D printing, or low-volume injection molding.

This approach is ideal for companies that need cost-effective short runs without the heavy investment in large-scale tooling. By producing small batches, businesses can evaluate real-world functionality, refine designs, and respond quickly to market feedback before committing to mass manufacturing.

Why Choose GD Prototyping for Small Batch Production?

At GD Prototyping, we specialize in helping businesses transition smoothly from concept to market. Our small batch prototyping services provide the flexibility and speed required for dynamic product development.

-

Versatile Manufacturing Processes: Access to CNC machining, 3D printing, vacuum casting, and low-volume injection molding.

-

Rapid Turnaround: Faster production cycles compared to mass manufacturing.

-

Cost Efficiency: Affordable alternative to full-scale tooling for limited quantities.

-

High-Quality Results: Production-grade finishes and functionality, suitable for testing or direct use.

-

Scalable Solutions: Seamless transition from prototypes to pilot runs and mass production.

-

Custom Finishing Options: Painting, texturing, and polishing to replicate production-ready products.

Choosing GD Prototyping means working with a partner who understands the balance between speed, quality, and cost-efficiency. We ensure your prototypes not only meet performance standards but also create a strong impression for investors, customers, and stakeholders.

Applications of Small Batch Prototyping

-

Product Testing & Validation: Evaluate design, fit, and functionality before mass production.

-

Market Validation: Produce limited units for customer trials, investor presentations, or pre-launch campaigns.

-

Bridge Manufacturing: Fill the gap between prototyping and large-scale production runs.

-

Custom & Specialty Products: Create tailored, limited-edition components for niche markets.

-

Consumer Electronics: Small series of casings, housings, and functional parts for testing and marketing.

-

Automotive & Aerospace: Low-volume runs of durable, precision components for testing and pilot programs.

-

Medical Devices: Short runs of sterilization-ready, biocompatible parts for clinical trials and user feedback.

Small batch prototyping bridges the gap between one-off prototypes and full-scale production, offering manufacturers an efficient way to test, validate, and launch new products. It involves producing limited runs of functional parts—often in quantities from a few units up to several hundred—using methods such as CNC machining, vacuum casting, 3D printing, or low-volume injection molding.

This approach is ideal for companies that need cost-effective short runs without the heavy investment in large-scale tooling. By producing small batches, businesses can evaluate real-world functionality, refine designs, and respond quickly to market feedback before committing to mass manufacturing.

Why Choose GD Prototyping for Small Batch Production?

At GD Prototyping, we specialize in helping businesses transition smoothly from concept to market. Our small batch prototyping services provide the flexibility and speed required for dynamic product development.

-

Versatile Manufacturing Processes: Access to CNC machining, 3D printing, vacuum casting, and low-volume injection molding.

-

Rapid Turnaround: Faster production cycles compared to mass manufacturing.

-

Cost Efficiency: Affordable alternative to full-scale tooling for limited quantities.

-

High-Quality Results: Production-grade finishes and functionality, suitable for testing or direct use.

-

Scalable Solutions: Seamless transition from prototypes to pilot runs and mass production.

-

Custom Finishing Options: Painting, texturing, and polishing to replicate production-ready products.

Choosing GD Prototyping means working with a partner who understands the balance between speed, quality, and cost-efficiency. We ensure your prototypes not only meet performance standards but also create a strong impression for investors, customers, and stakeholders.

Applications of Small Batch Prototyping

-

Product Testing & Validation: Evaluate design, fit, and functionality before mass production.

-

Market Validation: Produce limited units for customer trials, investor presentations, or pre-launch campaigns.

-

Bridge Manufacturing: Fill the gap between prototyping and large-scale production runs.

-

Custom & Specialty Products: Create tailored, limited-edition components for niche markets.

-

Consumer Electronics: Small series of casings, housings, and functional parts for testing and marketing.

-

Automotive & Aerospace: Low-volume runs of durable, precision components for testing and pilot programs.

-

Medical Devices: Short runs of sterilization-ready, biocompatible parts for clinical trials and user feedback.