Sheet Metal

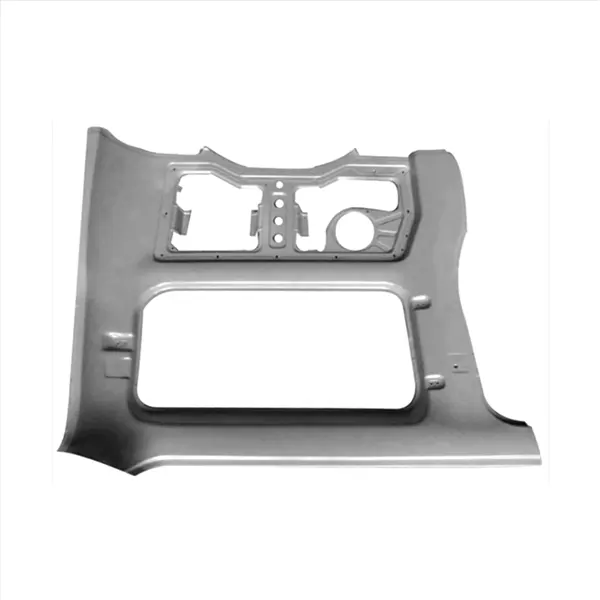

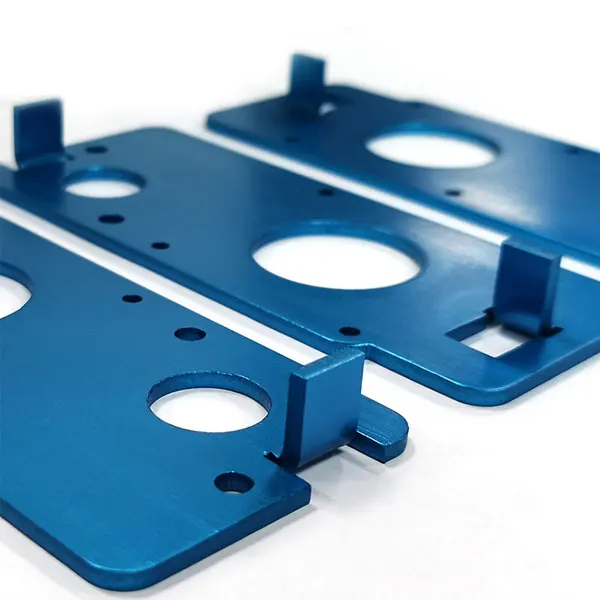

Sheet metal prototyping is a manufacturing process that transforms thin sheets of metal into functional prototypes and low-volume production parts. Using techniques such as laser cutting, bending, stamping, and welding, sheet metal prototyping delivers components with excellent durability, dimensional accuracy, and functionality.

This method is widely used in industries requiring enclosures, housings, brackets, and structural components. It enables manufacturers to test and validate designs quickly before committing to large-scale production.

Why Choose GD Prototyping for Sheet Metal Parts?

At GD Prototyping, we provide advanced sheet metal prototyping services that combine craftsmanship with cutting-edge equipment. Our team ensures each part is produced to exact specifications, with superior surface finishes and mechanical performance.

-

Precision Engineering: Tight tolerances and accurate dimensions for prototypes that match production intent.

-

Material Versatility: Wide range of metals including aluminum, stainless steel, brass, and copper.

-

Comprehensive Services: Laser cutting, bending, stamping, CNC machining, and welding in one place.

-

Custom Finishing: Options such as powder coating, anodizing, painting, and plating for both appearance and protection.

-

Fast Turnaround: Streamlined processes to accelerate development and reduce lead times.

-

Scalable Production: From one-off prototypes to small-batch runs for pilot programs.

When you partner with GD Prototyping, you gain reliable sheet metal solutions that deliver both functionality and market-ready aesthetics.

Applications

-

Electronics Enclosures: Durable housings, chassis, and casings for consumer and industrial devices.

-

Automotive Components: Brackets, panels, and protective covers for testing and functional use.

-

Aerospace & Defense: Lightweight yet strong structural parts for demanding applications.

-

Medical Equipment: Sterile and corrosion-resistant housings, trays, and components.

-

Industrial Machinery: Wear-resistant and load-bearing sheet metal parts for heavy-duty environments.

Sheet metal prototyping is a manufacturing process that transforms thin sheets of metal into functional prototypes and low-volume production parts. Using techniques such as laser cutting, bending, stamping, and welding, sheet metal prototyping delivers components with excellent durability, dimensional accuracy, and functionality.

This method is widely used in industries requiring enclosures, housings, brackets, and structural components. It enables manufacturers to test and validate designs quickly before committing to large-scale production.

Why Choose GD Prototyping for Sheet Metal Parts?

At GD Prototyping, we provide advanced sheet metal prototyping services that combine craftsmanship with cutting-edge equipment. Our team ensures each part is produced to exact specifications, with superior surface finishes and mechanical performance.

-

Precision Engineering: Tight tolerances and accurate dimensions for prototypes that match production intent.

-

Material Versatility: Wide range of metals including aluminum, stainless steel, brass, and copper.

-

Comprehensive Services: Laser cutting, bending, stamping, CNC machining, and welding in one place.

-

Custom Finishing: Options such as powder coating, anodizing, painting, and plating for both appearance and protection.

-

Fast Turnaround: Streamlined processes to accelerate development and reduce lead times.

-

Scalable Production: From one-off prototypes to small-batch runs for pilot programs.

When you partner with GD Prototyping, you gain reliable sheet metal solutions that deliver both functionality and market-ready aesthetics.

Applications

-

Electronics Enclosures: Durable housings, chassis, and casings for consumer and industrial devices.

-

Automotive Components: Brackets, panels, and protective covers for testing and functional use.

-

Aerospace & Defense: Lightweight yet strong structural parts for demanding applications.

-

Medical Equipment: Sterile and corrosion-resistant housings, trays, and components.

-

Industrial Machinery: Wear-resistant and load-bearing sheet metal parts for heavy-duty environments.