3D Printing

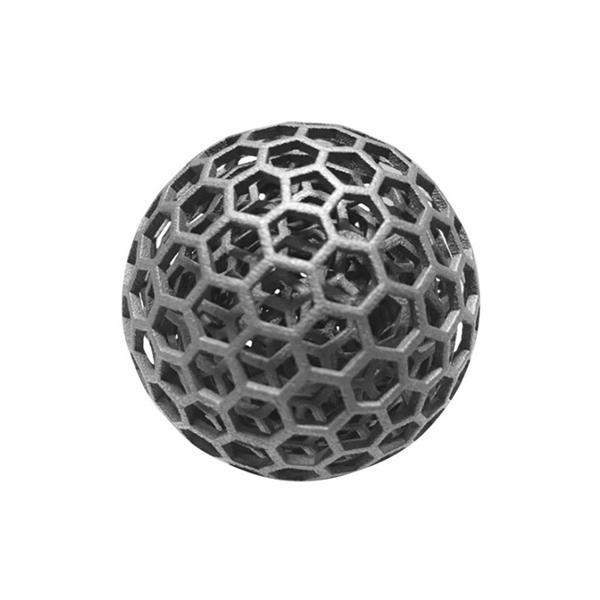

A 3D printing prototype case demonstrates the flexibility and effectiveness of additive manufacturing in product development. Unlike traditional methods, 3D printing builds parts layer by layer directly from digital CAD models, enabling rapid design iterations, complex geometries, and cost-effective prototyping.

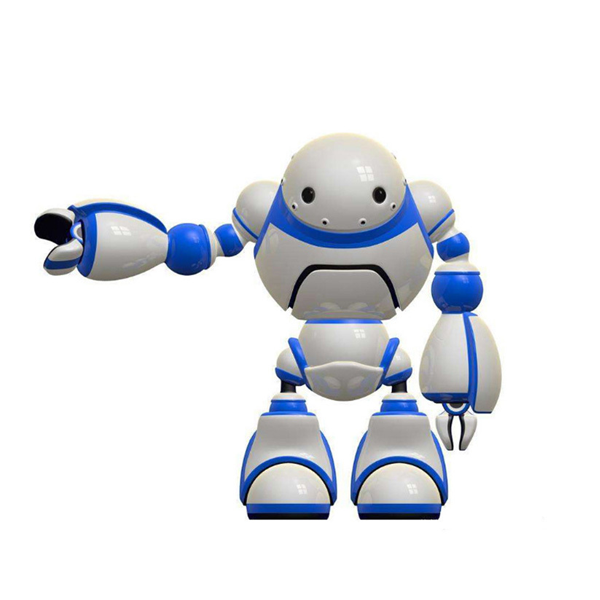

Prototyping with 3D printing allows businesses to validate concepts, test ergonomics, and assess functionality within days instead of weeks. Whether for visual models, functional prototypes, or small-batch production, 3D printing prototype cases provide a fast and reliable bridge between design and manufacturing.

Why Choose GD Prototyping for 3D Printing Prototype Cases?

At GD Prototyping, we offer end-to-end 3D printing services tailored to your specific design requirements. Our expertise spans multiple additive technologies, including SLA, SLS, FDM, and DMLS, ensuring we select the best method for your application.

-

Rapid Prototyping: Quickly turn CAD designs into tangible parts.

-

Complex Geometries: Create intricate designs that are difficult with traditional methods.

-

Material Versatility: Wide range of plastics, resins, and metals available.

-

Cost-Efficient Development: Save on tooling and setup costs.

-

Custom Finishes: Post-processing options such as painting, polishing, and texturing.

-

Scalability: From single prototypes to short production runs.

With GD Prototyping, you benefit from precision, flexibility, and speed, helping accelerate innovation and reduce development risks.

Applications of 3D Printing Prototype Cases

-

Design Validation: Produce realistic prototypes to test dimensions, fit, and ergonomics.

-

Functional Testing: Create durable parts for mechanical and environmental evaluation.

-

Medical Devices: Biocompatible prototypes for surgical planning and clinical testing.

-

Automotive & Aerospace: Lightweight, strong prototypes for performance analysis.

-

Consumer Products: Market-ready samples for presentations, exhibitions, and user feedback.

-

Industrial Equipment: Custom jigs, fixtures, and low-volume parts for testing.

A 3D printing prototype case demonstrates the flexibility and effectiveness of additive manufacturing in product development. Unlike traditional methods, 3D printing builds parts layer by layer directly from digital CAD models, enabling rapid design iterations, complex geometries, and cost-effective prototyping.

Prototyping with 3D printing allows businesses to validate concepts, test ergonomics, and assess functionality within days instead of weeks. Whether for visual models, functional prototypes, or small-batch production, 3D printing prototype cases provide a fast and reliable bridge between design and manufacturing.

Why Choose GD Prototyping for 3D Printing Prototype Cases?

At GD Prototyping, we offer end-to-end 3D printing services tailored to your specific design requirements. Our expertise spans multiple additive technologies, including SLA, SLS, FDM, and DMLS, ensuring we select the best method for your application.

-

Rapid Prototyping: Quickly turn CAD designs into tangible parts.

-

Complex Geometries: Create intricate designs that are difficult with traditional methods.

-

Material Versatility: Wide range of plastics, resins, and metals available.

-

Cost-Efficient Development: Save on tooling and setup costs.

-

Custom Finishes: Post-processing options such as painting, polishing, and texturing.

-

Scalability: From single prototypes to short production runs.

With GD Prototyping, you benefit from precision, flexibility, and speed, helping accelerate innovation and reduce development risks.

Applications of 3D Printing Prototype Cases

-

Design Validation: Produce realistic prototypes to test dimensions, fit, and ergonomics.

-

Functional Testing: Create durable parts for mechanical and environmental evaluation.

-

Medical Devices: Biocompatible prototypes for surgical planning and clinical testing.

-

Automotive & Aerospace: Lightweight, strong prototypes for performance analysis.

-

Consumer Products: Market-ready samples for presentations, exhibitions, and user feedback.

-

Industrial Equipment: Custom jigs, fixtures, and low-volume parts for testing.