GD Prototyping

SLS 3D Printing Metal

-

Materials: Stainless steel (316L, 17-4 PH), aluminum alloys, titanium alloys (Ti-6Al-4V), nickel-based alloys (Inconel 718, 625)

-

Build Volume: Up to 250 × 250 × 300 mm (depending on machine)

-

Layer Thickness: 20–60 microns

-

Tolerance: ±0.1–0.2 mm depending on geometry and size

-

Surface Finish: As-sintered matte finish; can be polished, machined, or coated

-

Production Capability: From single prototypes to small-batch and low-volume production

- Description

- Specification

- Application

- FAQS

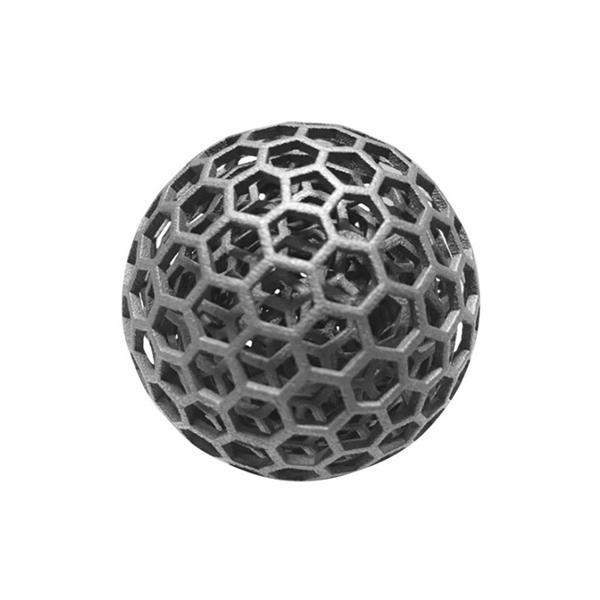

SLS 3D printing metal is an advanced additive manufacturing process that builds functional metal parts directly from digital models. It uses a high-powered laser to fuse fine metal powders, layer by layer, into dense and durable components. Because no molds or tooling are required, you can create designs with internal channels, lattice structures, and intricate details.

You can choose from materials such as stainless steel, aluminum, titanium, Inconel, and cobalt chrome. These metals offer strong mechanical performance and allow use in environments that demand wear resistance, corrosion resistance, and structural integrity. As a result, parts are ready for functional testing or direct end-use.

This process serves industries including aerospace, medical devices, automotive, energy, and industrial tooling. For example, you can produce custom implants, lightweight brackets, turbine components, and engine parts. Since the method is additive rather than subtractive, it supports efficient geometries while helping reduce material waste and production time.

After printing, you can enhance parts through post-processing. Options include heat treatment, CNC machining, polishing, and surface finishing. These steps improve tolerances, meet specific surface requirements, and refine the overall appearance.

SLS 3D printing metal works well for prototyping and low-volume production. It enables quick design changes and short lead times, which is valuable for rapid iteration and pilot runs. Moreover, it can reduce costs when producing complex parts that would be challenging to machine conventionally.

By integrating SLS 3D printing metal into your workflow, you can streamline assembly and lower part counts. Additionally, you gain the flexibility to explore innovative designs without sacrificing performance or material capability.

| Parameter | Value / Description |

|---|---|

| Printing Technology | DMLS |

| Layer Thickness | 0.02 – 0.06 mm |

| Typical Applications | Aerospace parts, medical implants, tooling, automotive components |

| TFile Formats Supported | STL, 3MF, OBJ |

- Aerospace:Lightweight, high-strength parts like turbine blades and brackets.

- Automotive:Custom engine components, performance parts, and tooling.

- Medical:Personalized implants, prosthetics, and surgical tools.

- Tooling:Custom jigs, fixtures, molds, and production tools.

- Industrial:Functional parts like valves, pumps, and heat exchangers.

- Energy & Oil:High-performance parts for drilling and turbine applications.

- Defense:Specialized components for military equipment.

- Prototyping & Small Batches:Rapid prototyping and low-volume production of metal parts.

Q1: What is SLS 3D Printing Metal?

It’s a process where a high-powered laser sinters fine metal powders to build functional, dense, and durable metal parts layer by layer.

Q2: What metals can be printed using SLS?

We work with stainless steel, aluminum alloys, titanium alloys, and nickel-based superalloys.

Q3: How strong are SLS metal parts?

They have comparable mechanical properties to forged or cast parts, making them suitable for functional and end-use applications.

Q4: Is SLS 3D printing cost-effective?

Yes, especially for low-volume production or highly complex parts where traditional methods are expensive.

Q5: Can SLS parts be post-processed?

Absolutely—parts can be polished, machined, coated, or heat-treated for improved performance and aesthetics.