GD Prototyping

Sheet Metal Bending And Welding

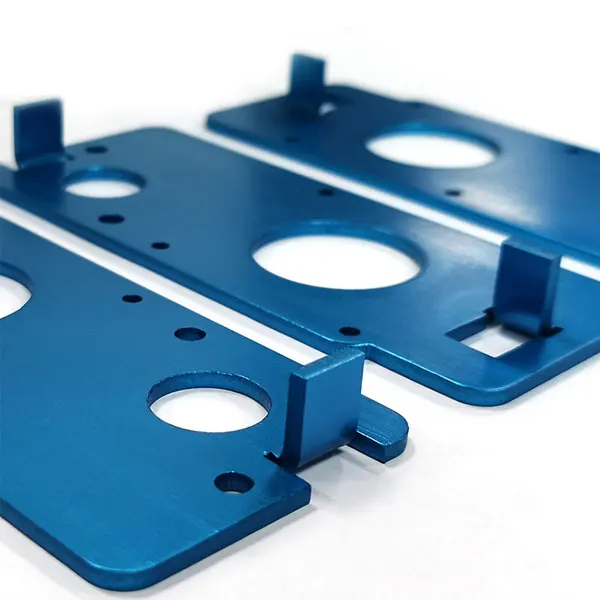

At GD Prototyping We have rich experience in making sheet metal parts, like CNC stamping, cutting, bending and welding.

Classification:

Sheet Metal

Keywords:

- Sheet Metal

- bending

- Sheet Metal Processing

- Description

- Specification

- Application

- FAQS

Sheet metal processing includes drilling, cutting, bending, welding, riveting, and other methods to shape thin metal plates into parts. Common materials are steel, stainless steel, aluminum, copper, titanium, and galvanized plates. These materials offer options for strength, corrosion resistance, and weight. The process is efficient, precise, and flexible. It suits small batch and multi-variety production runs well.

Sheet metal bending and welding are key steps in making strong, complex parts. Bending applies force to shape metal into angles or curves without breaking it. This creates components with strong structural integrity and various profiles, from simple bends to detailed shapes. Welding joins metal pieces to form assemblies or add strength. It produces strong joints that endure mechanical stress and harsh environments.

GD Prototyping has rich experience in producing many types of sheet metal parts. We make chassis, cabinets, equipment shells, advertising machine shells, and electronic hardware enclosures. We also handle stainless steel sheet metal products, monitoring system equipment shells, automation equipment housings, medical equipment shells, outdoor cabinets, power outdoor cabinets, and highway peripheral equipment shells. Our expertise includes sheet metal chassis and sample parts.

Our services include CNC stamping, cutting, bending, and welding. CNC stamping forms precise features quickly and repeatedly. Cutting methods like laser cutting and shearing provide clean, accurate edges. During bending, we shape parts to exact specifications with consistent angles and curves. Welding joins parts securely to create durable assemblies ready for use or further processing.

These bending and welding methods let us produce sheet metal parts that meet many industry needs, especially in communications, automotive, and home appliances.

| Parameter | Value / Description |

|---|---|

| Process Name | Sheet metal processing |

| Processing Methods | Drilling, cutting, bending, welding, riveting, CNC stamping |

| Materials Used | Steel, stainless steel, aluminum, copper, titanium plate, galvanized plate |

| Production Suitability | Small batch and multi-variety processing |

- Communications industry

- Automotive industry

- Home appliance industry

1. What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of cutting, bending, and assembling flat metal sheets into desired shapes or products. It involves techniques like laser cutting, punching, welding, and forming to create parts for various industries.

2. What materials are commonly used in sheet metal fabrication?

Common materials include stainless steel, aluminum, carbon steel, copper, and brass. The choice of material depends on the application, required strength, corrosion resistance, and appearance.

3. What are the advantages of using sheet metal for manufacturing?

Sheet metal offers high strength-to-weight ratio, durability, cost-effectiveness, and excellent precision. It's also versatile and suitable for mass production, prototyping, and custom part fabrication.

4. What thicknesses are available for sheet metal?

Sheet metal typically ranges from 0.5 mm to 6 mm thick. Thinner sheets are used for lightweight applications, while thicker sheets are chosen for structural or heavy-duty uses.

5. What industries commonly use sheet metal parts?

Industries like automotive, aerospace, electronics, medical devices, appliances, and construction use sheet metal for components such as enclosures, brackets, chassis, panels, and structural supports