GD Prototyping

MJF 3D Printing

-

Materials: PA12 nylon, PA11 nylon, glass-filled nylon, flexible TPU

-

Build Size: Up to 380 × 284 × 380 mm (per build chamber)

-

Layer Thickness: 80 microns

-

Tolerance: ±0.2 mm or ±0.2% (whichever is greater)

-

Surface Finish: Smooth matte gray/black; can be dyed or post-processed

-

Batch Capability: From single prototypes to hundreds of units

- Description

- Specification

- Application

- FAQS

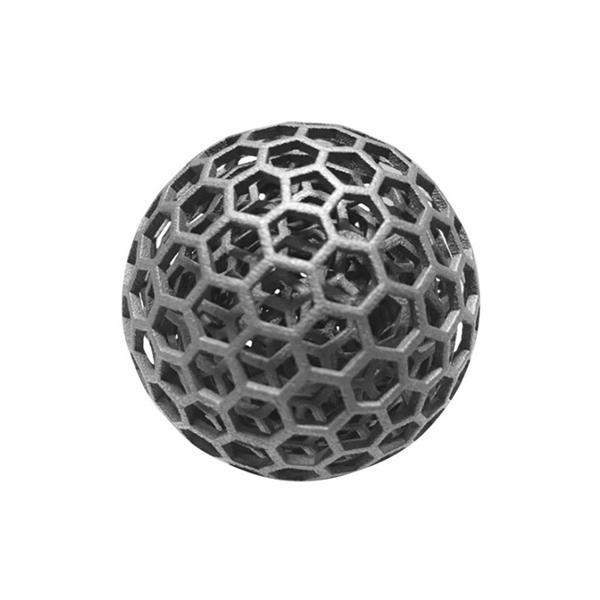

MJF 3D Printing is a high-performance additive manufacturing process that produces strong and functional nylon parts. It works by applying fusing and detailing agents to a thin layer of nylon powder. A heat source then fuses the areas defined by the agents. This process builds parts layer by layer with speed and precision.

You can use MJF 3D Printing to create both prototypes and end-use components without needing tooling or molds. It suits low- to mid-volume production, short development cycles, and design changes. The process allows you to print multiple parts in one build, which saves time and lowers the cost per unit.

MJF parts offer consistent mechanical properties in all directions. They show good surface quality and hold tight tolerances, even on complex geometries. Because of this, they work well for brackets, housings, fixtures, jigs, and functional assemblies. Common industries include automotive, consumer products, medical devices, and industrial tools.

This method also enables efficient nesting of parts with different shapes and sizes. You can print complete part sets or mixed orders in a single production run. After printing, you can apply surface treatments such as dyeing or vapor smoothing to improve appearance or performance.

Compared to other powder-based methods, MJF offers faster build times and better surface consistency. The fine resolution captures design features accurately, reducing the need for secondary finishing.

You can rely on this process for fast delivery and repeatable quality. Whether you need a few parts for testing or hundreds for pilot production, MJF helps meet your schedule and design goals. The flexibility it provides makes it suitable for both custom applications and series production.

By choosing MJF 3D Printing, you gain a practical option for rapid manufacturing with durable materials and reliable results.

| Parameter | Value / Description |

|---|---|

| Surface Finish | Matte gray finish |

| Layer Thickness | 0.08 mm |

| Print Speed | Up to 4115 cm³/hr |

| Material Type | Nylon PA12 (most common), PA11, TPU, PP, and other thermoplastics |

- Functional Prototypes:Durable, test-ready parts for fit, form, and function validation.

- End-Use Parts:Small to medium batch production of final-use components.

- Consumer Products:Housings, clips, wearables, and custom accessories.

- Automotive:Brackets, ducts, enclosures, and lightweight structural parts.

- Medical Devices:Custom orthotics, prosthetics, and device casings (non-implant).

- Electronics:Cable organizers, mounts, and protective casings.

- Industrial Equipment:Gears, jigs, fixtures, and custom replacement parts.

- Footwear & Fashion:Custom midsoles, accessories, and design prototypes.

1. What is MJF 3D printing?

MJF (Multi Jet Fusion) is a powder-bed 3D printing technology developed by HP that uses fusing and detailing agents with infrared energy to create strong, functional thermoplastic parts.

2. What materials are used in MJF?

Common materials include PA12, PA11, TPU, and polypropylene—offering durability, flexibility, and chemical resistance.

3. What are the benefits of MJF compared to other 3D printing methods?

MJF provides excellent part strength, fast print speed, fine detail resolution, and isotropic mechanical properties.

4. Is MJF suitable for end-use parts?

Yes, MJF is widely used for producing functional, production-grade parts in small to medium volumes.

5. What is the typical surface finish of MJF parts?

Parts usually have a matte gray finish, which can be improved through post-processing like dyeing, polishing, or vapor smoothing.