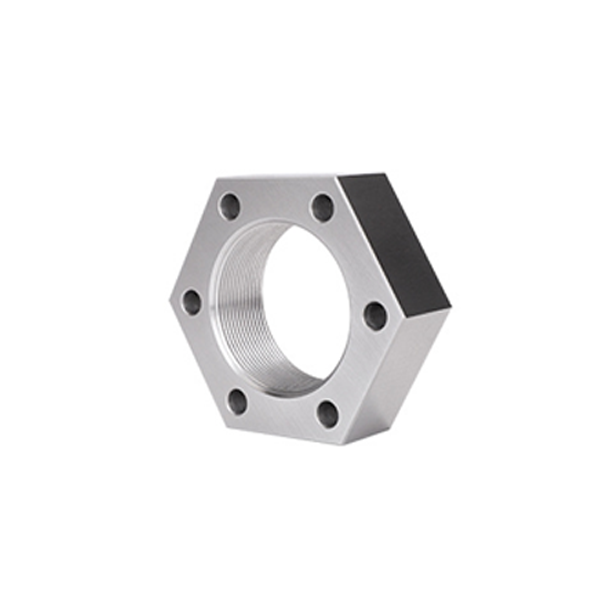

GD Prototyping

Low Volume Manufacturing

-

Batch Size: 50 to several thousand units

-

Processes: CNC machining, injection molding, casting, 3D printing, sheet metal

-

Materials: Aluminum, stainless steel, titanium, plastics, composites, alloys

-

Tolerance: As tight as ±0.005 mm (depending on process)

-

Surface Treatments: Anodizing, powder coating, plating, polishing, painting

-

Lead Time: Rapid turnaround with flexible scheduling

- Description

- Specification

- Application

- FAQS

At GD Prototyping, we provide Low Volume Manufacturing services to bridge the gap between prototyping and mass production. This approach is ideal for companies that require high-quality parts in limited quantities, whether for testing, pilot production, or specialized market needs. Unlike large-scale manufacturing, low volume production allows businesses to validate designs, reduce financial risk, and bring products to market faster.

Our state-of-the-art facility supports low-volume runs across a wide range of processes, including CNC machining, sheet metal fabrication, vacuum casting, injection molding, die casting, and additive manufacturing. We work with metals, plastics, and composite materials to deliver functional, durable, and aesthetically refined components.

Every project is backed by ISO-certified quality control to ensure that each part meets strict standards for accuracy, surface finish, and performance.

With GD Prototyping, low volume doesn’t mean compromise—it means speed, precision, and flexibility tailored to your needs.

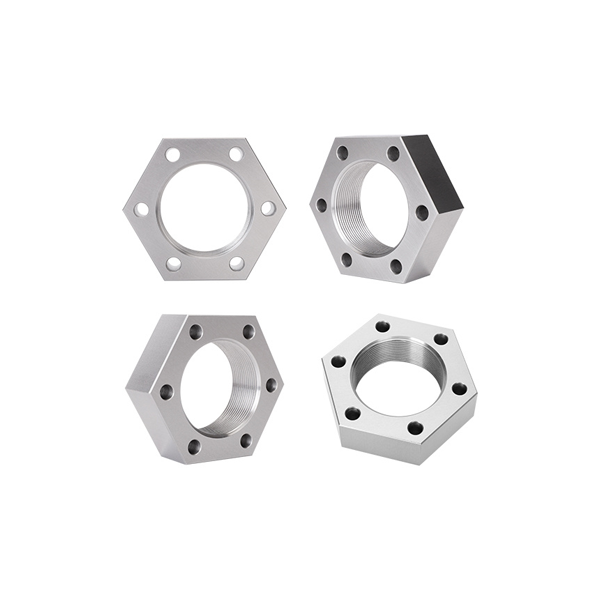

| Parameter | Value / Description |

|---|---|

| Material Options | Metals (Aluminum, Steel, Brass, Titanium), Plastics (ABS, PC, Nylon, POM, etc.) |

| Tolerance Range | ±0.01 mm – ±0.3 mm (depending on process and material) |

| Manufacturing Methods | CNC machining, 3D printing, vacuum casting, sheet metal fabrication, low-volume molding |

- Product Prototyping:Ideal for early-stage development, functional testing, and design validation.

- Pilot Production Runs:Small batches to test manufacturing feasibility and market response before scaling up.

- Customized Components:Tailored parts for specialized equipment, one-off builds, or niche industries.

- Medical Devices:Custom instruments, diagnostic parts, and patient-specific components.

- Consumer Electronics:Short-run plastic and metal housings, internal brackets, and functional enclosures.

1. What is small quantity manufacturing?

It refers to producing parts or products in limited volumes—typically from 1 to 1000 units—using flexible, cost-effective methods like CNC machining, 3D printing, or vacuum casting.

2. What are the benefits of small batch production?

Lower upfront costs, faster turnaround, design flexibility, and no need for expensive tooling—ideal for prototyping, testing, or custom parts.

3. What manufacturing methods are used?

Common processes include CNC machining, SLA/SLS 3D printing, sheet metal fabrication, vacuum casting, and low-volume injection molding.

4. What materials are available?

A wide range of plastics (e.g., ABS, PC, PA, POM) and metals (e.g., aluminum, stainless steel, brass, titanium) are supported.

5. Is it suitable for functional end-use parts?

Yes. Many small batch parts are used in real-world applications, especially when produced with engineering-grade materials.