Metal Prototype Machining | Custom Prototyping Services

Metallic Prototyping: Accuracy for All Industries Major Benefits of CNC Machining of Metal Prototypes The sophisticated CNC milling/turning achieves accuracy at the micron level, making it an ideal use in engineering prototype machining where a small change of dimensions can impact the performance. As options and applications of CNC technology extend in the usage of ... Read more

On Demand 3D Printing Services | Custom Additive Manufacturing

What is On-Demand 3D Printing? The principle of additive manufacturing or 3D printing is the direct opposite of the usual machining, which is subtractive. As opposed to cutting and carving material out of a block, on demand 3D printing services create an entire object by coating bottom layers with layers of material and adding new ... Read more

Plastic Injection Prototyping | Rapid Molding & Custom Solutions

What is Plastic Injection Prototyping? What is its Functionality? Plastic injection molding is a manufacturing process that is used in the production of various plastic products and parts. The machine heats molten plastic and injects the plastic into the mold, where the plastic solidifies and becomes the completed part. It involves pouring the molten plastic ... Read more

Precision Automotive Parts Machining | CNC Auto Components

Concepts of Precision Automotive Parts Machining Precision automotive parts machining entails the production of complex parts of a vehicle using computer numerical control (CNC) machines. These systems are used to steer the cutting tools with greater accuracy (micrometers) to achieve high precision metalworking, and these systems are capable of meeting the demanding requirements of the ... Read more

Prototyping Manufacturing Services: Precision Solutions for Modern Industries

What are Prototyping Manufacturing Services? Prototyping manufacturing services entail designing initial models or working samples of a product prior to full-scale production. These prototypes enable engineers and designers to test, refine, and prove their designs. Services typically include: Manufacturers are able to create quality, durable, and performance prototypes with the help of advanced technologies such ... Read more

Sheet Metal Bending and Welding | CNC Fabrication Services

Sheet Metal Bending and Welding Precision Fabrication The metal fabrication world, which is dynamic, requires sheet metal bending and welding to produce a creation that is strong, durable, and engineered accurately to create a component. It can be a smooth automotive panel, it can be a strong aerospace bracket, it can be a custom industrial ... Read more

Sheet Metal Housing Fabrication: Bending & Welding Experts

What is Housing Fabrication Sheet Metal? The mechanism, which includes the planning, production, and assembly of a metal casing with metal of superior-quality sheet metal, is the sheet metal housing fabrication. They are housing that are put to diverse use, e.g.: The modern sheet metal housings are more exact, stable, and resilient than ever because ... Read more

SLS 3D Printing Metal: The Future of Additive Manufacturing

What is SLS 3D Printing? A 3D printing technology called Selective Laser Sintering (SLS) is powder-based and uses a powerful laser to heat the particles of the material in a group to a solid form. In contrast to traditional manufacturing, SLS is additively manufactured, whereby the parts are created in layers. The laser sinters selectively ... Read more

Small Batch 3D Printing Services | Cost-Effective Production

Small Batch 3D Printing Rapid, Economic, and Efficient Small batch 3D printing helps the manufacturers produce small quantities of components in a short duration and at low cost, and this can be accomplished within days and not months, as in the case of conventional practices. Additive manufacturing (AM) in low-volume production is not only faster ... Read more

Stainless Steel 304 Machining | CNC Manufacturing Experts

Introduction Stainless steel 304 machining is an aid in precision engineering. The 304 (also referred to as 18-8) stainless steel is an amalgamation of resistance to corrosion, strength, and versatility. As mentioned, grade stainless steel 304 is the most common variety. Still, it does not imply that it is simple to machine 304. It gets ... Read more

Stainless Steel Parts Machining: CNC Solutions for Every Industry

What are Stainless Steel Parts Machining? The stainless steel parts machining is the process of transforming stainless steel materials into certain parts through CNC milling, turning, and multi-axis machining. The processes are used to machine material off solid stainless steel blocks to tight tolerances and complex geometries demanded by industry. The properties of stainless steel, ... Read more

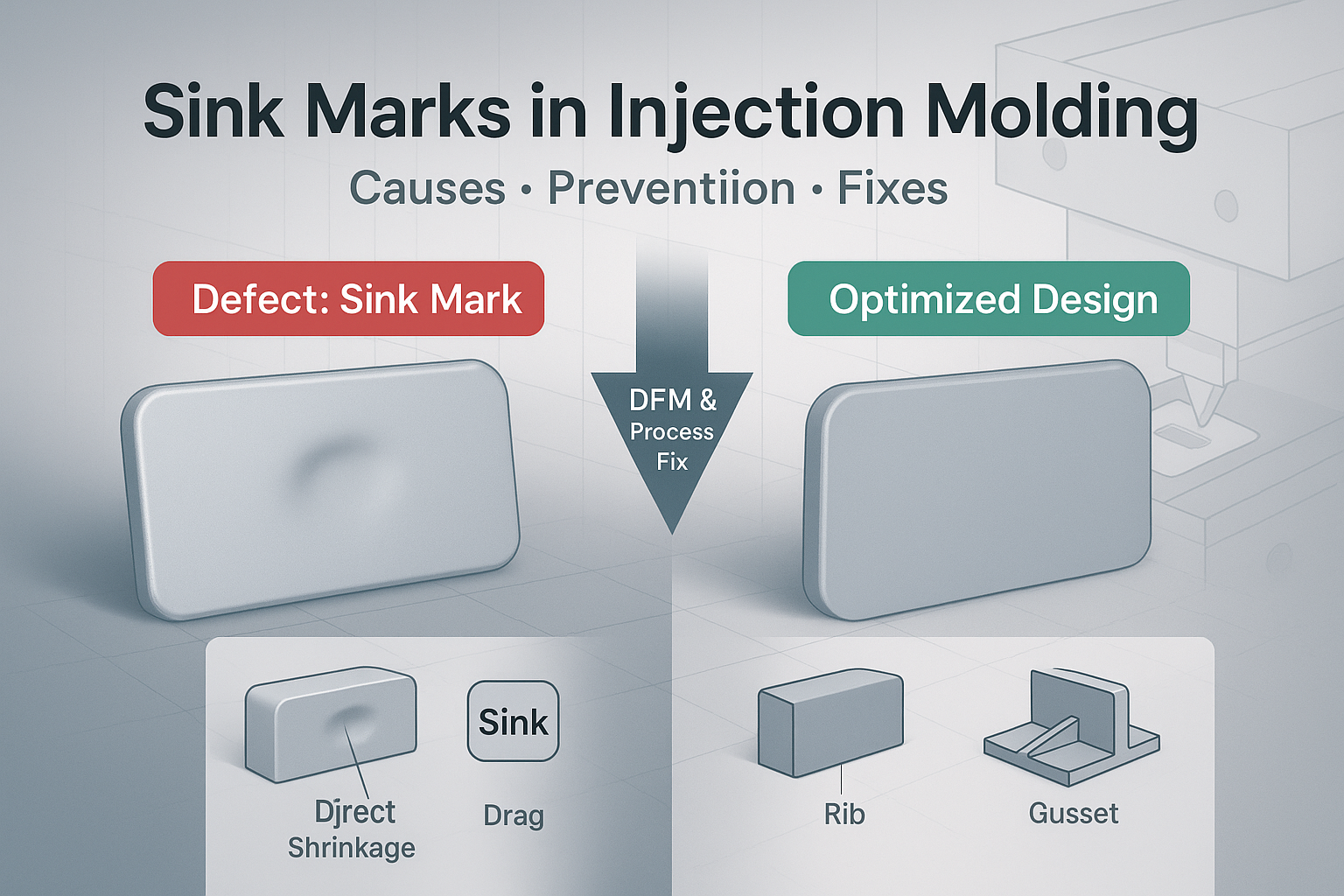

Sink Marks in Injection Molding: Causes & Fixes

An engineer can spend months perfecting a product's design. Every curve and feature is meticulously planned. Yet, when the first parts come out of the injection mold, the design can be marred by unsightly surface depressions. These flaws are known as sink marks. They are the most common and frustrating cosmetic defect in injection molding. ... Read more