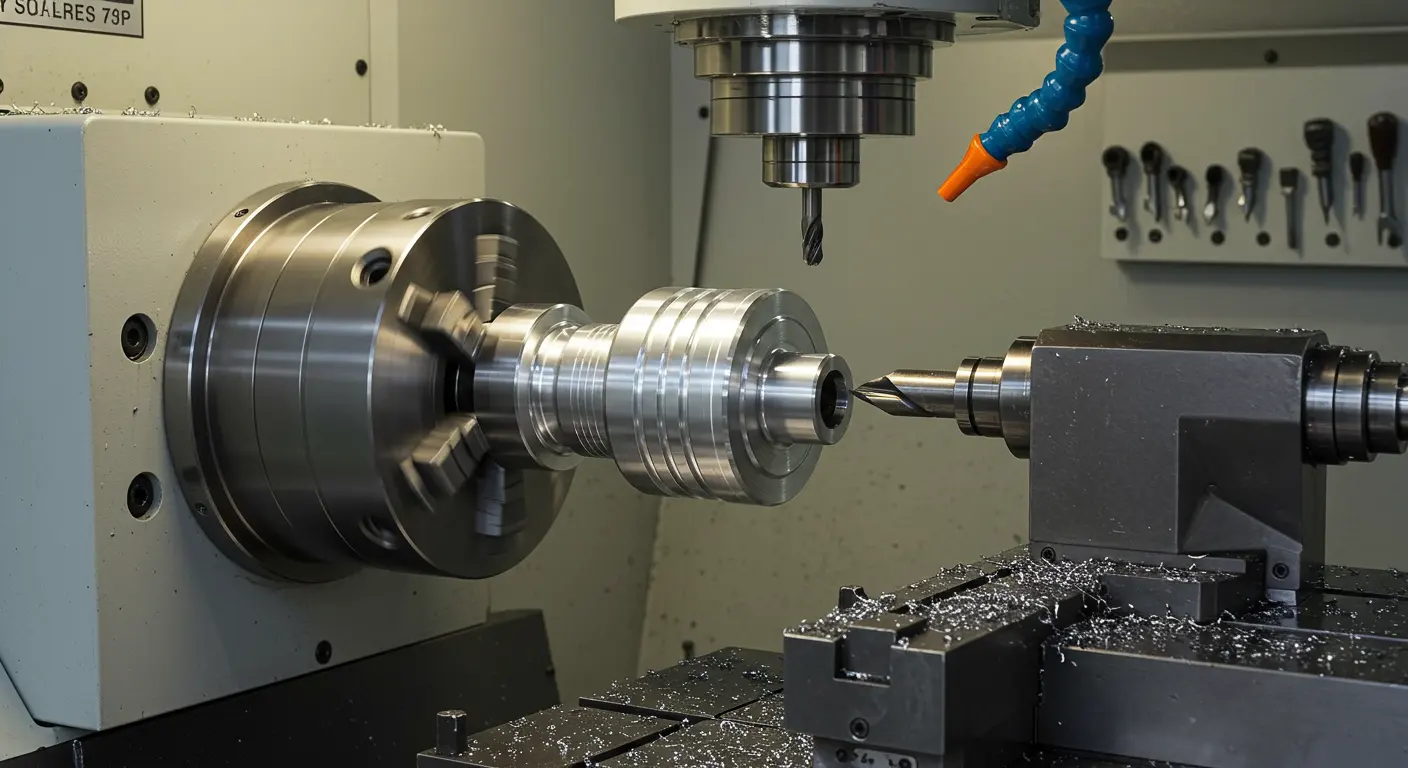

Automotive Parts CNC Machining | Custom CNC Manufacturing

What is CNC Machining of Automotive Parts? The production of metal and plastic components of vehicles by the use of computer numerical control (CNC) systems is known as automotive parts CNC machining. It is able to cut, mill, drill, and turn raw materials, including aluminum, steel, brass, and titanium, precisely and form them into complex ... Read more

Automotive Prototype Manufacturing | Car Prototype & Design Services

The Introduction of Automobile Prototype Production In the modern, fast-changing automotive industry, automotive prototype manufacturing is a very imperative factor in the intermediation between the concept design and mass production. Prototyping can be used to verify designs, material testing, and performance of autonomous car components, whether it is a next-generation electric vehicle (EV) or car ... Read more

Brass Parts CNC Machining | High-Precision Brass Components

Engineered Precision of High-Performance Parts The world of current-day manufacturing has seen the birth of brass parts CNC machining as a standard of excellence in the field of precision, durability, and performance. Taking the effectiveness of the CNC machining process and the peculiarities of brass, the given manufacturing technique is appointed the most common way ... Read more

CNC Machining Service Quote | Instant Online CNC Pricing

Ultimate Guide to CNC Price Accurately and Instantly Precision and time are all in the modern manufacturing industry, which is fast-moving. It could be a prototype, a multi-part automotive component, custom parts used in aerospace or medical applications, or any other project that requires CNC machining services to be realized. The first thing is to ... Read more

CNC Milling Prototype Services | High-Precision Machining

What is CNC Milling Prototyping? CNC Milling Prototypes Services: Innovation, Accuracy, and Reliable Quality The Purpose of the CNC Milling is to Create the Prototype Prototypes also have a significant role in developing a new product since they are applied to test, prove, and determine the viability of the product. CNC milling gives unbelievable control ... Read more

CNC Surface Finishing | Precision CNC Polishing & Surface Treatment

What is QCNC Surface Finishing? Surface finishing in CNC machining is used to refers to the finishing applied to the surface of a part by a secondary machining process after the primary machining process to improve the surface roughness, texture, and aesthetic appearance of the part. The finish determines the smoothness, reflective, or functional nature ... Read more

CNC Turning Prototyping Services | Custom Precision CNC Turned Parts

What is CNC Turning Prototyping? CNC Turning Prototyping: The Art of Standing Still and Light Speed Product Creation In this rapidly changing manufacturing environment of modern times, CNC turning prototyping has emerged as one of the cornerstone technologies that has amalgamated precision machining technology, fast manufacturing services, and digital innovation into a single powerful process. ... Read more

Custom Machining Stainless Steel | CNC Precision Parts 2025

Why Use Custom Machining on Stainless Steel? It is also a famous property of stainless steel that it is resistant to corrosion, thermally stable, and strong, and therefore, it can be used in severe conditions. But its machinability may be a problem because of the effects of work-hardening, wear of the tool, and heat during ... Read more

Custom Resin Prototyping | SLA & Rapid 3D Printing Services

What is Custom Resin Prototyping? Custom resin prototyping is the application in additive manufacturing of photopolymer resin materials (often known as fabricated prototyping) to produce functional resin models, high-resolution prototypes, and final-use components. It is done using either SLA (Stereolithography), Digital Light Processing (DLP), or LCD resin printing technology, and each one demands dimensional precision, ... Read more

Injection Molding for Prototypes | Rapid Tooling & Molding

Prototyping By Injection Molding Prototypes: Intelligent Approach When it comes to product development, it is speed, accuracy, and cost efficiency that will make or break a product. Once the business goes beyond the idea stage into reality, injection molding for prototypes is what links the design and manufacturing stages. This is a sophisticated procedure through ... Read more

Low Volume 3D Printing Production | Custom Additive Services

3D Printing Production: Sharpening of the Contemporary Production Learning About Low Volume 3D Printing Production Low volume 3d printing production is the production of a small number of parts (usually between 10 and 1,000 parts) through the additive manufacturing technologies. It is an intermediate step between prototype and full-scale production, providing a cost-efficient, agile, and ... Read more

Low Volume Vacuum Casting | Prototype & Small Batch Production

What is Low Volume Vacuum Casting? Vacuum Casting Process: An Overview Let's consider the operation of vacuum casting of low-volume production- a technique very popular in prototype production and testing product designs. This starts with the creation of a master model, typically created through CNC machining, or additive manufacturing substitutes, like 3D printing. The model ... Read more