A Complete Guide to Anodizing: Type II vs Type III

For parts made from aluminum, anodizing is one of the most effective and popular finishing processes available. It is not a coating like paint or plating. Instead, it is an electrochemical process that enhances the natural oxide layer on the aluminum's surface. This creates a finish that is durable, corrosion-resistant, and aesthetically pleasing. However, "anodizing" is not a single, monolithic process. It is a family of different specifications. The two most common and important types are Type II and Type III.

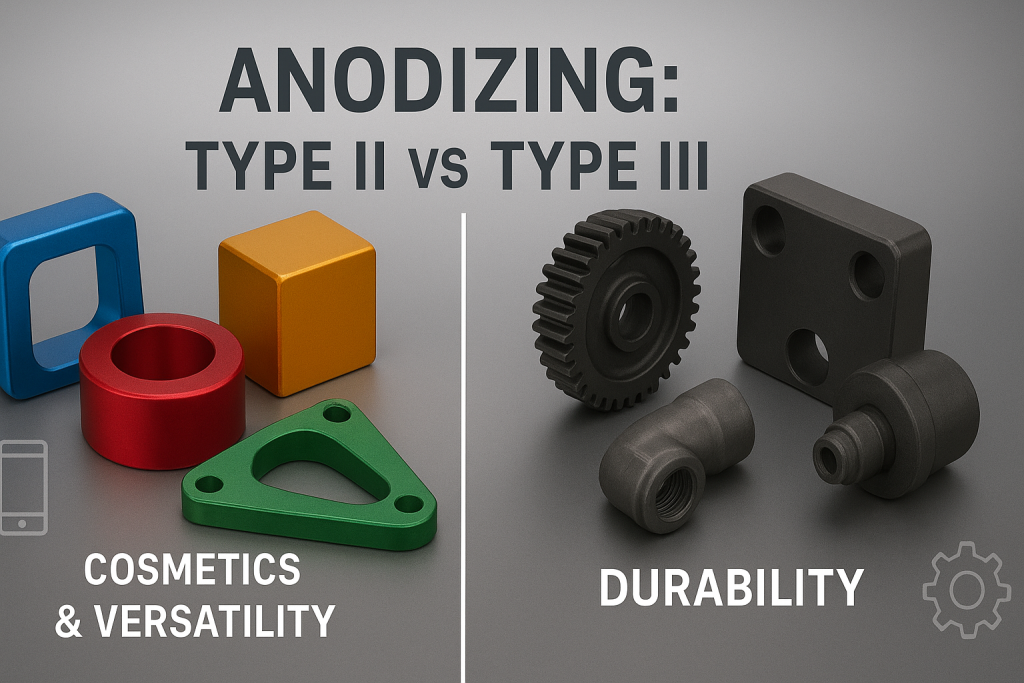

The primary difference between Type II and Type III anodizing is the thickness and hardness of the resulting aluminum oxide layer. Type II is a thinner, primarily cosmetic finish with good corrosion resistance, while Type III (hardcoat) is a much thicker, harder, and more durable coating designed for high-performance engineering applications. Choosing between them is a critical decision. It depends entirely on the functional requirements and intended environment of the aluminum component.

As an expert in the precision finishing of aluminum components, GD-Prototyping has deep, hands-on experience with both conventional and hardcoat anodizing. This guide provides a comprehensive, technical comparison. We will explore the process differences, the resulting properties, and the ideal use cases for each. This will empower you to make the right choice for your project.

The Science of Anodizing: A Quick Refresher

To understand the difference between Type II and Type III, it is first essential to understand the fundamental science of how anodizing works. The process is a marvel of controlled electrochemistry.

How Does Anodizing Work?

Anodizing is an electrolytic passivation process. The aluminum part is thoroughly cleaned and then submerged in a bath of an acid electrolyte. The part is connected to the positive terminal of a DC power supply, making it the "anode." A cathode (typically lead or aluminum plates) is also placed in the bath.

When the electric current is applied, it causes a chemical reaction. Water molecules are broken down at the surface of the aluminum anode. Oxygen ions are released, which immediately bond with the aluminum atoms on the part's surface. This process grows a highly structured, uniform layer of aluminum oxide. This engineered oxide layer is much thicker and more durable than the thin, chaotic oxide layer that forms naturally on aluminum in the open air.

The Porous Aluminum Oxide Layer

The anodic layer has a unique and highly organized microscopic structure. It is composed of millions of tightly packed, hexagonal columnar cells. Each cell has a tiny pore in the center. This porous, honeycomb-like structure is the key to one of anodizing's most popular features: coloring. The pores are able to absorb organic dyes, allowing the part to be colored in a wide variety of vibrant, metallic shades.

The Sealing Process

After the oxide layer has been grown and, if desired, dyed, there is one final, critical step: sealing. The anodized part is submerged in a bath of hot deionized water or a chemical sealant solution. This process hydrates the aluminum oxide, causing the pores to swell and close up. Sealing the surface is essential. It locks in the dye. More importantly, it dramatically improves the corrosion resistance of the coating by preventing contaminants from entering the pores.

A Deep Dive into Type II Anodizing (Conventional)

Type II anodizing is the most common and widely used form of the process. It is the standard for a huge range of consumer and industrial products. Its official designation comes from the military specification MIL-A-8625, which defines Type II as "Sulfuric Acid Anodizing."

What is Type II Anodizing?

Type II is a conventional anodizing process. It is designed to create a protective and cosmetic finish with a moderate thickness. It provides an excellent balance of performance, appearance, and cost, making it the default choice for most applications.

The Process Parameters

The specific operating conditions of the anodizing process are what define it as Type II.

- Electrolyte: The bath is a solution of sulfuric acid.

- Temperature: The process is run at or near room temperature, typically around 21°C (70°F).

- Current Density: A moderate electrical current density is used, typically in the range of 12-18 amps per square foot.

These relatively mild conditions allow for the growth of a very regular, orderly porous oxide layer.

The Resulting Oxide Layer

The Type II process produces an aluminum oxide layer of moderate thickness. The thickness is a key specification and typically ranges from 5 to 25 microns (µm), which is equivalent to 0.0002 to 0.001 inches. Approximately two-thirds of this layer penetrates into the base material, and one-third builds up on the surface. The cellular structure of this layer is very uniform and highly porous, which makes it ideal for accepting color dyes.

Key Properties of Type II

- Cosmetic Appearance: This is the primary strength of Type II. The clear, porous layer can be dyed to produce a vast range of bright, vibrant, and metallic colors. The final appearance is durable and will not chip or peel like paint.

- Corrosion Resistance: Type II provides good corrosion protection for aluminum parts in most normal atmospheric and marine environments. A properly sealed Type II finish can withstand hundreds of hours of salt spray testing.

- Hardness and Wear Resistance: The aluminum oxide layer is significantly harder than the raw aluminum underneath. However, because the layer is relatively thin, Type II is not considered a high-wear-resistance finish. It protects against mild scratching and abrasion but can be worn through in demanding mechanical applications.

- Electrical Insulation: Aluminum oxide is an excellent electrical insulator. The Type II coating will prevent the part from conducting electricity.

Common Applications for Type II

The versatility of Type II makes it ubiquitous.

- Consumer Electronics: Housings for smartphones, laptops, and audio equipment.

- Architectural Components: Window frames, railings, and decorative panels.

- Sporting Goods: Bicycle components, flashlight bodies, and rock climbing gear.

- Automotive: Interior trim, knobs, and decorative exterior parts.

A Deep Dive into Type III Anodizing (Hardcoat)

Type III anodizing, commonly known as "hardcoat," is an industrial process. It is designed to create a finish where performance, not aesthetics, is the primary concern. Its official designation is "Hard Anodic Coating."

What is Type III (Hardcoat) Anodizing?

Hardcoat anodizing is an engineered surface treatment. It produces an aluminum oxide layer that is significantly thicker, denser, and harder than a conventional Type II coating. It is used to create functional surfaces on aluminum parts that can withstand extreme wear, abrasion, and harsh corrosive environments.

The Process Parameters

The exceptional properties of a hardcoat finish are achieved by dramatically altering the process parameters.

- Electrolyte: The process often uses a more concentrated sulfuric acid solution, sometimes with organic additives.

- Temperature: This is the most critical difference. The hardcoat process is run at a much lower temperature, typically at or near freezing, around 0°C (32°F). Chilling the acid bath is a major energy and equipment requirement.

- Current Density: A much higher electrical current density is used, typically in the range of 24-36 amps per square foot.

This combination of high current and low temperature forces the oxide layer to grow in a very dense, less organized, and much thicker manner.

The Resulting Oxide Layer

The hardcoat process produces a very thick and dense aluminum oxide layer. The typical thickness ranges from 25 to 75 microns (µm), or 0.001 to 0.003 inches, though it can be thicker. Approximately 50% of this coating penetrates the surface, and 50% builds up on top. This significant dimensional growth must be accounted for in the initial part design. The cellular structure is much less porous and more chaotic than a Type II layer.

Key Properties of Type III

- Extreme Hardness and Wear Resistance: This is the primary reason for choosing Type III. The hardcoat layer is exceptionally hard, often reaching 60-70 on the Rockwell C scale. This is harder than many tool steels. It provides outstanding resistance to abrasion, erosion, and mechanical wear.

- Superior Corrosion Resistance: The thick, dense, and well-sealed hardcoat layer offers the highest level of corrosion protection possible for aluminum. It can withstand thousands of hours of salt spray testing.

- Color Limitations: The dense, often dark natural color of the hardcoat layer makes it very difficult to dye. Colors are generally limited to dark shades like black. The natural, undyed color of a hardcoat finish can range from a light bronze to a dark grey, depending on the alloy and the coating thickness.

- Significant Dimensional Impact: The thick coating adds a measurable amount of thickness to every surface of the part. Engineers must design their parts with this buildup in mind to ensure that final tolerances are met.

The Head-to-Head Comparison: Type II vs. Type III

This table provides a clear, at-a-glance summary of the critical differences between the two anodizing processes.

| Attribute | Type II (Conventional) | Type III (Hardcoat) |

| Primary Purpose | Cosmetic finish, standard corrosion protection. | Engineering performance, extreme wear resistance. |

| Coating Thickness | 5 - 25 µm (0.0002" - 0.001") | 25 - 75 µm (0.001" - 0.003") |

| Hardness (Rockwell C) | ~20 - 40 HRC | ~60 - 70 HRC |

| Wear Resistance | Fair | Excellent |

| Color Options | Excellent (Wide range of vibrant colors) | Poor (Limited to dark colors, primarily black) |

| Relative Cost | $$ | $$$$ |

| Typical Specification | MIL-A-8625, Type II, Class 2 (Colored) | MIL-A-8625, Type III, Class 1 (Undyed) |

Use Cases: Making the Right Choice for Your Application

The choice between Type II and Type III should be driven by the part's function and its intended operating environment.

When Should You Specify Type II Anodizing?

When the primary goal is a decorative or cosmetic finish. If your product needs a specific, vibrant, metallic color, Type II is the only choice.

For parts that require good corrosion resistance in a normal atmospheric or mildly corrosive environment. This includes most consumer and commercial products.

For products like consumer electronics housings, architectural elements, automotive interior trim, and sporting goods.

When the part does not have high-wear requirements and is not subject to significant mechanical abrasion.

When Should You Specify Type III (Hardcoat) Anodizing?

Choose the high-performance hardcoat when:

- The part is a dynamic component that will experience sliding or abrasive wear against other parts. Examples include pistons, valves, and moving machinery components.

- The part will be used in a harsh or highly corrosive environment, such as in marine or aerospace applications.

- Maximum durability and abrasion resistance are the top priorities, and cosmetic appearance is secondary.

- The application requires a rugged, non-reflective finish, such as for military and defense equipment.

Design and Process Considerations

Engineers must be aware of several key factors when designing parts for anodizing.

The Impact on Tolerances

The anodic coating adds thickness to the part. For Type II, this buildup is small. For Type III, it is significant. This dimensional change must be accounted for in the initial engineering drawing to ensure that final part tolerances are met after finishing.

Sharp Edges and Corners

The anodizing process has poor "throwing power" on sharp external corners. This means the coating can be very thin and brittle at these points. A best practice is to design parts with a small radius on all external corners to ensure a uniform and durable coating.

Material Alloy Choice

Not all aluminum alloys anodize equally well. Alloys in the 6xxx series (like 6061) and 5xxx series are excellent candidates for cosmetic Type II anodizing. High-zinc 7xxx series alloys can be hardcoated but may have a more yellow/brown natural color. High-silicon casting alloys are often very difficult to anodize to a consistent, high-quality finish.

Racking and Contact Points

To be anodized, a part must be held on a rack to conduct electricity. The points where the rack touches the part will be left un-anodized. These small "contact points" must be located on non-critical, non-cosmetic surfaces of the part. Anodizing is not the only option for corrosion protection. For some applications where conductivity is required, a comparison of Alodine vs Anodize is necessary. The final finish is also related to the initial Surface Roughness of the part.

Conclusion

The choice between Type II and Type III anodizing is a clear decision between aesthetics and performance. Type II (conventional) anodizing offers a versatile and cost-effective solution for creating beautiful, colorful parts with good protection against everyday corrosion. Type III (hardcoat) anodizing is a high-performance engineering solution. It transforms the surface of an aluminum part into a rugged, wear-resistant ceramic that can survive in the most demanding applications.

Understanding the difference between these two powerful processes is essential for any engineer designing with aluminum. At GD-Prototyping, our expertise covers the full spectrum of finishing options. We can help you select and specify the perfect anodized finish to ensure your components meet their highest potential for both appearance and performance.