What Problems Does Aluminum Rapid Tooling Actually Solve?

Aluminum Rapid Tooling is reshaping the way manufacturers move from a clean CAD model to a real, testable part in hand. Instead of waiting for a slow, expensive steel mold, teams can now run trials, build assemblies, and prepare for launch while their competitors are still "waiting on tooling."

At GD Prototyping, we see the same story again and again in aerospace, automotive, medical, and industrial projects: deadlines are tight, designs keep changing, and tooling budgets are under pressure. Aluminum Rapid Tooling is one of the most practical tools we use to break that deadlock and get products moving.

What Aluminum Rapid Tooling Really Means on the Shop Floor

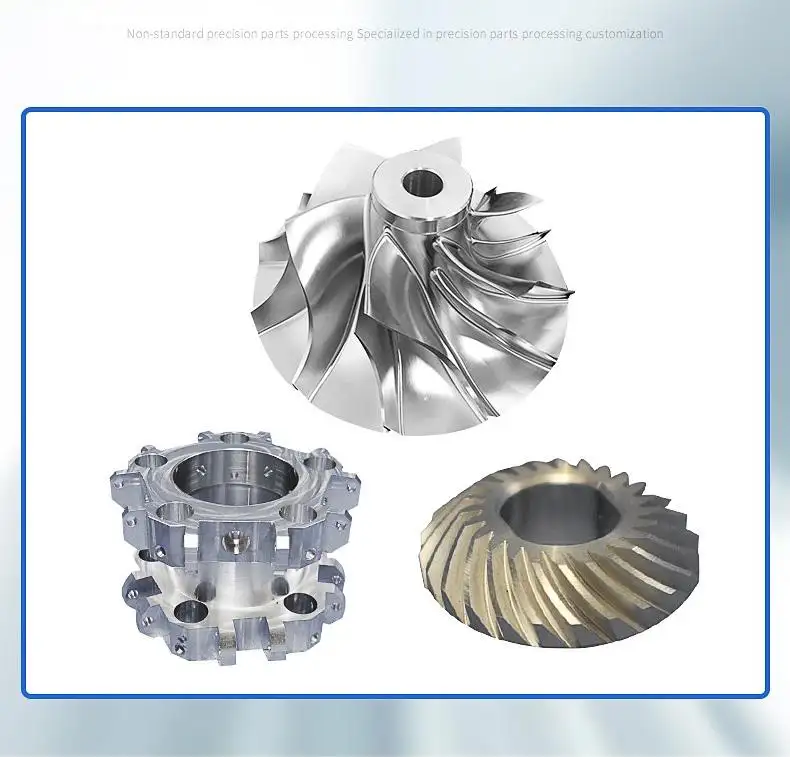

In simple terms, Aluminum Rapid Tooling uses CNC-machined aluminum molds or inserts to produce prototype and low-volume parts. It sits between quick 3D prints and a full production steel tool. You get real molded parts, in near-production materials, without jumping straight into a big, irreversible tooling investment.

Inside GD Prototyping, we rely on advanced 3-axis, 4-axis, and 5-axis CNC machining to create precise aluminum tooling components. On critical features, we can reach tolerances around ±0.005 mm, which is tight enough for demanding assemblies, sealing surfaces, and functional testing. That means the same tool can deliver parts for both visual reviews and serious engineering evaluations.

Around the core aluminum mold, we can add inserts and metal elements in materials such as stainless steel, titanium, brass, copper, and specialized alloys. This lets us tune tool life, heat transfer, and wear resistance to match your resin choice and expected shot count.

For many customers, Aluminum Rapid Tooling becomes a strategic development tool, not just a faster way to cut a mold. It lets them check:

✅ Whether part geometry and draft angles are realistic

✅ How cooling and warpage behave in real molding conditions

✅ If gate and ejector layouts work as planned

✅ How the part fits with other components in the assembly

All of this can be done before you sign off on a high-cost steel mold that needs to last for years.

Four Painful Problems Aluminum Rapid Tooling Helps Solve

1. Endless Lead Times and Slipping Launch Dates

You know the situation: engineering is ready, marketing has campaigns booked, but the tool is still in progress. Traditional tooling, especially hardened steel molds, can take months. Every delay pushes back samples, certifications, and revenue.

Because aluminum is faster to machine and easier to modify, Aluminum Rapid Tooling compresses this critical phase. Using efficient CNC strategies, we can often deliver molds in a fraction of the time needed for full production tooling. That translates into very concrete advantages:

✅ Design validation happens earlier in the project

✅ Pilot builds and internal testing can begin sooner

✅ There's more time to react to feedback from customers, regulators, and internal teams

For companies racing toward a trade show, funding milestone, or contract deadline, those extra weeks are often worth far more than the cost of the tool.

2. High Tooling Spend, High Nerves

There's also the financial stress:

"You're still not 100% sold on the design, but everyone says it's time to order the production mold."

Signing off on an expensive steel tool while the design is still moving is a big risk. Any later change can mean costly rework, insert swaps, or starting again from scratch.

Aluminum rapid tooling gives you a safer way forward. Because the initial investment is lower than hardened steel, you can:

✅ Prove out the part's fit and function without overspending

✅ See how the market responds before you commit to the final tool

✅ Soften the financial hit when changes inevitably show up

Instead of a one-shot "hope we're right" decision, you move step by step: rapid aluminum tool first to learn, then production tooling once you know you've got it right.

3. Slow, Painful Design Changes During Development

Modern products rarely stay frozen after the first prototype. Industrial design tweaks the look and feel, engineering refines wall thickness and ribs, and major customers ask for new options. With a traditional tool, each change feels heavy: long downtime, tooling rework, and extra cost.

Because it is easier and faster to machine, Aluminum Rapid Tooling makes design changes much more manageable. Our team at GD Prototyping can re-cut inserts, adjust details, or create new cores and cavities quickly, while still maintaining the tight tolerances needed for assembly and performance.

This iterative tooling strategy is most valuable when:

✅ Critical tolerances require tuning based on empirical test data

✅ Unproven or difficult-to-process materials are under evaluation

✅ Several design configurations need to be qualified in parallel for different customers or markets

Aluminum Rapid Tooling reframes tooling from a fixed capital asset into an adaptable engineering tool that can change as your design matures.

4. Real-World Production and Quality Unknowns

Simulation results and 3D-printed samples are great starting points, but they don't tell the whole story. Real injection molding conditions can reveal surprises - flow marks, sink, warpage, or assembly issues - that only show up when you're running molded parts in the actual (or very close to actual) production material.

With Aluminum Rapid Tooling, you can mold parts under realistic processing parameters and test them where it matters:

- Under-the-hood automotive environments with high temperature swings

- Aerospace brackets and housings that see mechanical loads and vibration

- Medical device components that need to survive cleaning and sterilization

Identifying problems at this stage is far cheaper than discovering them after you've already invested in a full production tool and committed to a long tooling lead time.

How GD Prototyping Supports Your Entire Development Cycle

At GD Prototyping, we don't see Aluminum Rapid Tooling as a standalone service. We combine it with our Precision Metal Parts Machining capabilities to support you from first functional prototype through bridge production and into early market launch.

Our CNC equipment line-up allows us to hit tight tolerances on molds, inserts, and critical metal components, so your parts line up with your CAD data and fit smoothly into downstream assemblies, jigs, and fixtures. Where surfaces are important, we can achieve fine industrial-grade finishes that reduce polishing work or improve part appearance.

To match your functional and visual requirements, we provide a variety of finishing options, including:

✅ Anodizing for improved wear resistance and corrosion protection

✅ Plating and polishing for smoother movement or enhanced conductivity

✅ Bead blasting and powder coating for clean, consistent visuals on metal components

Our engineers also support you with DFM reviews, gate and parting line suggestions, basic flow considerations, and material selection guidance. Together, we look at where Aluminum Rapid Tooling fits best in your project:

- Prototype molds to generate real parts for testing and approvals

- Bridge tooling to cover low-volume or pilot runs before full production

- Flexible early-stage production for niche, customized, or frequently updated products

Rather than forcing a standard package, we help you balance speed, cost, and tool life based on your actual project goals.

Ready to See What Aluminum Rapid Tooling Can Do for Your Product?

Share your 3D files and project requirements with GD Prototyping, and we'll suggest a tooling approach, estimated lead time, and suitable materials for your parts. Whether you need a few samples for internal tests or a short run to support first customer orders, we're here to help you move faster, reduce risk, and bring better parts to market with Aluminum Rapid Tooling.