Alodine vs Anodize (Chromate vs Anodizing): A Complete Guide

Aluminum is a remarkable material for manufacturing. It is lightweight, strong, and easy to machine. However, in its raw state, it is susceptible to corrosion and wear. To protect aluminum parts and enhance their performance, a surface finish is almost always required. Two of the most common and effective treatments are Alodine and Anodizing. While both are used to protect aluminum, they are fundamentally different processes. They produce coatings with vastly different properties. Choosing the wrong one can lead to product failure.

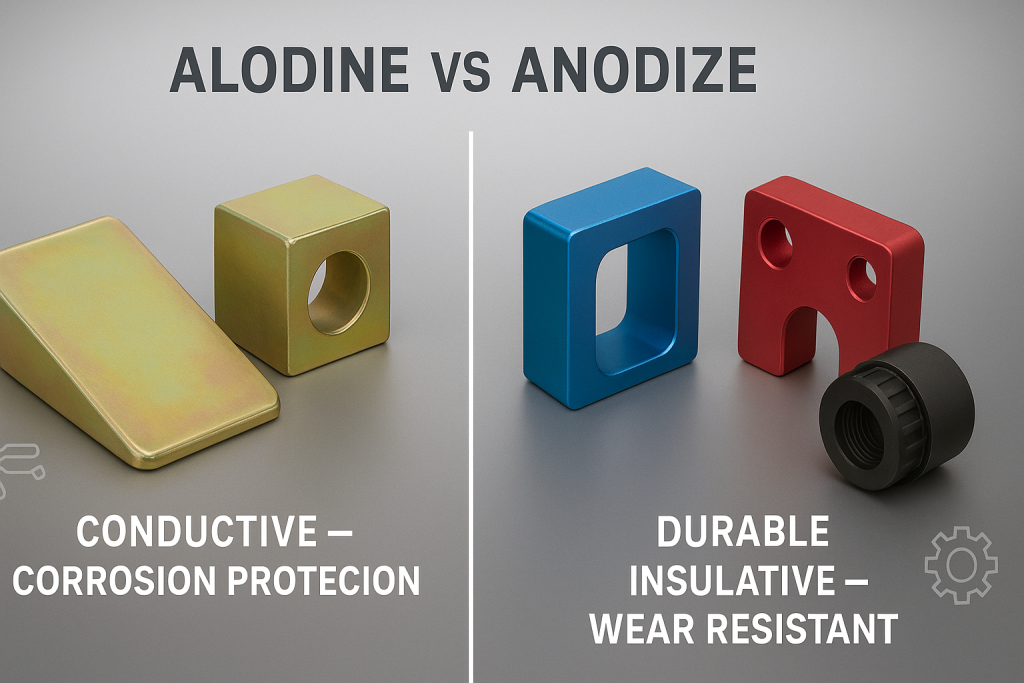

The primary difference between Alodine and Anodize is that Alodine (a chemical conversion coating) provides good corrosion resistance while remaining electrically conductive, whereas Anodizing (an electrochemical process) creates a much harder, more durable surface that is an excellent electrical insulator. This single distinction in conductivity is often the most critical factor in the selection process.

As experts in the precision finishing of aluminum components, GD-Prototyping guides clients through this critical choice daily. This guide provides a deep, technical comparison of these two essential finishes. We will explore the science behind each process. We will also detail their properties and ideal applications to help you make the right engineering decision.

A Deep Dive into Anodizing: The Electrochemical Process

Anodizing is one of the most popular and robust finishes for aluminum. It is a highly controlled process that creates a durable, protective layer by enhancing the natural oxide on the metal's surface. It is not a coating that is applied; it is a layer that is grown directly from the base aluminum.

How Anodizing Works

Anodizing is an electrochemical process. The aluminum part is first thoroughly cleaned and deoxidized. It is then submerged in a bath of an acid electrolyte, typically sulfuric acid. The part is connected to the positive terminal of a DC power supply, making it the "anode" in the electrical circuit. A cathode, usually made of lead or aluminum, is also placed in the bath.

When the electric current is applied, it causes a reaction at the surface of the aluminum part. The current forces the surface of the aluminum to oxidize in a highly accelerated and controlled manner. This process grows a uniform, porous layer of aluminum oxide. This engineered oxide layer is significantly thicker, harder, and more organized than the flimsy oxide layer that forms naturally on aluminum in the air.

The Structure of the Anodized Layer

The anodic layer has a unique and fascinating microscopic structure. It is composed of millions of tightly packed, hexagonal columns of aluminum oxide. Each column has a tiny, hollow pore in the center. This honeycomb-like structure is what makes the coating so versatile. The pores can be used to absorb organic dyes, allowing the part to be colored. After dyeing, the layer is sealed. This is usually done by dipping the part in hot deionized water. The hot water hydrates the aluminum oxide, causing it to swell and close off the pores, locking the dye inside. This sealing process is also what gives the coating its excellent corrosion resistance.

Key Properties of Anodized Finishes

Anodizing is chosen for its combination of durability and aesthetic appeal.

- Durability and Hardness: Aluminum oxide is a very hard ceramic material. The anodized layer is significantly harder and more scratch-resistant than the base aluminum. This protects the part from wear and abrasion.

- Corrosion Resistance: A properly sealed anodized layer provides an excellent barrier against moisture and environmental contaminants. It prevents the underlying aluminum from corroding.

- Electrical Insulation: This is a critical property. Aluminum oxide is a ceramic and an excellent electrical insulator. Anodized surfaces will not conduct electricity. This is a vital feature for electronic enclosures that must prevent short circuits.

- Aesthetics: The ability to dye the porous layer allows for a wide range of vibrant, metallic colors. The finish is also very stable and will not chip, peel, or flake like paint.

The performance of an anodized coating can vary significantly between different types. You can learn more in our detailed guide to Anodizing Type II vs III.

A Deep Dive into Alodine (Chromate Conversion Coating)

Alodine is a brand name that has become synonymous with a specific type of finish: a chromate conversion coating, often called "chem film." Unlike the complex electrochemical process of anodizing, Alodine is a much simpler chemical immersion process.

What is Alodine?

Alodine is a chemical conversion coating. It is not grown with electricity. Instead, it is formed by a chemical reaction between the aluminum surface and the chemical solution. The resulting coating is extremely thin. It provides corrosion protection and other unique properties without significantly changing the part's dimensions.

How Alodine Works

The process is fast and straightforward. The aluminum part is first cleaned and deoxidized. It is then simply dipped into a chemical bath containing chromic acid or chromium salts for a short period, often just a few minutes. A chemical reaction takes place on the surface of the aluminum. This reaction "converts" the top layer of the metal into a new, thin, protective film that is chemically bonded to the substrate. After the dip, the part is rinsed and allowed to dry. No electricity is used in the process.

The Structure of the Conversion Coating

The Alodine coating is fundamentally different from an anodized layer. It is not a thick, structured, crystalline layer. Instead, it is an extremely thin, gelatinous, and amorphous film. Its thickness is typically measured in nanometers. It is so thin that it adds virtually no measurable dimension or weight to the part. The coating has a characteristic iridescent color, often ranging from clear to a light, golden yellow.

Key Properties of Alodine / Chem Film

Alodine is chosen for a very specific set of functional properties.

- Good Corrosion Resistance: The thin film acts as a passive barrier. It prevents the aluminum surface from reacting with oxygen in the air, thus inhibiting corrosion. While not as robust as a thick anodized coating, it provides good protection in mild environments.

- Electrical Conductivity: This is the most important and defining benefit of Alodine. The coating is thin enough that it does not disrupt the electrical conductivity of the underlying aluminum. This makes it the ideal choice for any part that must maintain a good electrical ground or be part of an electrical circuit.

- Excellent Primer for Paint: The chemical nature of the conversion coating provides an exceptionally good surface for paint, powder coat, and adhesives to bond to. It dramatically improves the adhesion of subsequent finishes.

- Minimal Dimensional Change: Because the coating is extremely thin, it does not affect the dimensional tolerances of a precision-machined part. This is critical for components with very tight dimensional requirements.

The Head-to-Head Comparison: Alodine vs. Anodize Table

This table provides a direct, at-a-glance comparison of the two finishes, highlighting their fundamental differences.

| Attribute | Alodine (Chem Film) | Anodizing |

| Process Type | Chemical Immersion | Electrochemical |

| Coating Thickness | Extremely Thin (~0.1 - 2.0 µm) | Thick (5 - 75 µm) |

| Hardness / Durability | Soft / No abrasion resistance | Very Hard / Excellent abrasion resistance |

| Corrosion Resistance | Good | Excellent to Superior |

| Electrical Conductivity | Excellent (Conductive) | Poor (Insulator) |

| Suitability as a Primer | Excellent | Fair to Good |

| Color Options | Poor (Clear to yellow/gold) | Excellent (Full range of colors) |

| Relative Cost | $ | $$ |

The Deciding Factor: Electrical Conductivity Explained

For many projects, the choice between Alodine and Anodize comes down to a single, simple question: Does the part need to conduct electricity? This one property is the most critical differentiator and often makes the decision for the engineer.

When is an Insulative Surface Required?

An insulative surface is required when a part must prevent the flow of electricity. A common example is the outer housing of a piece of consumer electronics. The aluminum case must not be able to short-circuit the printed circuit boards (PCBs) and other components inside. In this application, anodizing is the only choice. Its thick, ceramic-like aluminum oxide layer is an excellent electrical insulator. This provides a durable, cosmetic, and electrically safe finish all in one.

When is a Conductive Surface Required?

A conductive surface is essential for any part that is part of an electrical circuit or is used for grounding and shielding.

- Electrical Grounding: Many electronic components must be grounded to the main chassis of the device to ensure safety and proper function. The surface of the chassis must be conductive at these contact points.

- EMI/RFI Shielding: An electronics enclosure must often act as a Faraday cage to prevent electromagnetic interference (EMI) or radio-frequency interference (RFI) from entering or exiting the device. To do this effectively, all panels of the enclosure must have good electrical conductivity between them.

In these applications, Alodine / chem film is the only choice. It provides the necessary corrosion protection without sacrificing the essential electrical conductivity of the aluminum.

Compatibility and Design Considerations

Both Alodine and Anodize are robust processes, but their success depends on the material choice and some key design considerations.

Aluminum Alloy Compatibility

Both finishes work best on aluminum alloys with a lower copper content, such as the 5xxx and 6xxx series. High-copper alloys (2xxx series) and high-silicon casting alloys can be difficult to finish with a consistent, high-quality appearance. The final color and uniformity of the finish are highly dependent on the specific alloy being used.

The Importance of Surface Preparation

The final quality of any finish is a direct result of the quality of the surface preparation. The part must be perfectly clean and free of oils, coolants, and other contaminants before it enters the chemical bath. The initial raw surface texture will also be visible through the final finish. A uniform surface is essential. Mechanical preparation like Bead Blasting vs Sandblasting is often a required first step to create a clean, consistent surface ready for finishing.

Designing for Masking

In some complex designs, a part may need both an insulative surface and a conductive one. For example, the majority of an electronics housing may need to be anodized for durability, but specific interior spots need to remain conductive for grounding. In this case, the conductive spots must be physically masked off with a plug or special tape before the part is anodized. This masking process adds significant manual labor and cost to the finishing process.

Environmental and Modern Alternatives

It is important to address the environmental aspect of chromate conversion coatings.

A Note on Hexavalent Chromium and Modern Alternatives

- Traditional Alodine processes use hexavalent chromium (Cr6+), which is a hazardous substance and a known carcinogen. Its use is heavily regulated in many parts of the world.

- In response to these regulations, the chemical industry has developed modern, chromium-free conversion coatings. These are often referred to as TCP-free (Trivalent Chromium Passivation) or non-chrome coatings.

- These newer, more environmentally friendly alternatives offer corrosion protection and conductivity that is comparable to traditional chromate coatings for many applications.

- They are increasingly becoming the new standard for industries like aerospace and defense, and they are an excellent choice for any company focused on sustainability and worker safety.

Conclusion

Alodine (chem film) and Anodizing are both excellent and essential surface treatments for aluminum. However, they are not interchangeable. They serve fundamentally different engineering purposes. The choice between them is a clear, function-driven decision.

If a part must be hard, durable, wear-resistant, or electrically insulative, Anodizing is the correct choice. If a part must be electrically conductive for grounding or EMI shielding, or if it will be painted later, Alodine is the correct choice.

Understanding this critical difference is key to designing functional and reliable aluminum components. At GD-Prototyping, our team of experts understands the nuances of both processes. We can provide the guidance needed to ensure you select the perfect finish to meet the specific technical requirements of your project.