Founded in 2010, GD Prototyping Technology (HK) Ltd has grown into a leading provider of prototyping manufacturing services with a strong global reputation for quality and innovation. Located in Chang’an Town, Dongguan, Guangdong, China, our state-of-the-art facility covers more than 12,000 square meters and is supported by over 300 highly skilled engineers, technicians, and manufacturing experts.

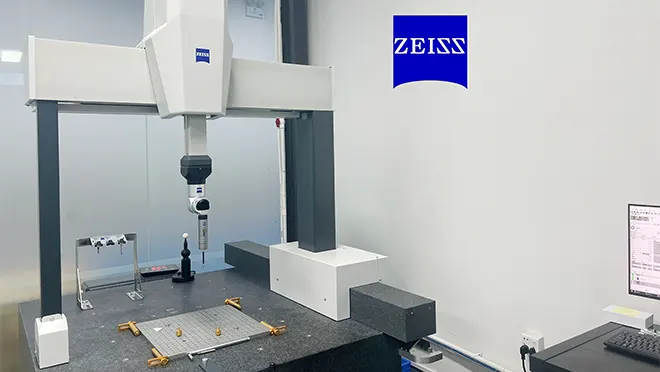

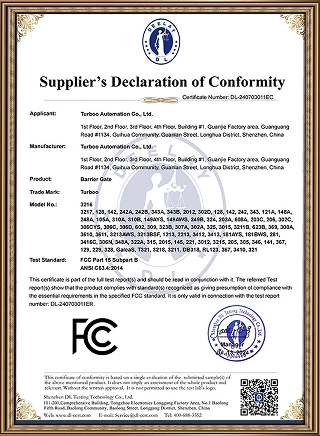

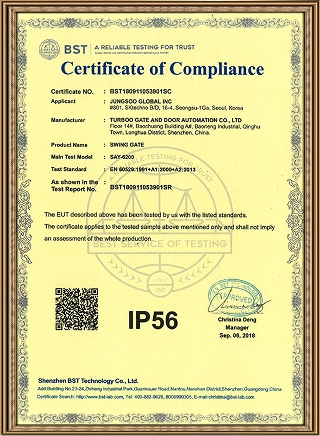

We are a certified contract manufacturer dedicated to delivering turnkey solutions for rapid prototyping, low-volume production, and high-complexity manufacturing. By combining advanced technology with strict quality control, GD Prototyping ensures that every part, component, or assembly meets the highest international standards.

Our Capabilities

Our full-service offering allows clients to move seamlessly from concept to production. We provide:

- CNC Milling & Turning – Precision machining with 3-axis, 4-axis, and 5-axis systems.

- Additive Manufacturing – SLA, SLS, and DMLS 3D printing for fast and complex builds.

- Sheet Metal Fabrication – High-accuracy bending, punching, welding, and stamping.

- Vacuum Casting & Silicone Molding – Ideal for prototypes and short production runs.

- Injection Molding & Die Casting – Scalable solutions for plastics and metals.

- Surface Treatments & Finishing – Including anodizing, plating, coating, polishing, and more.

Industries We Serve

With a broad technical foundation, we deliver tailored prototyping manufacturing services for a variety of industries, including:

- Automotive – Functional parts, housings, and precision components.

- Aerospace & Defense – Lightweight, high-performance components with strict tolerances.

- Medical Devices – Biocompatible prototypes, surgical tools, and custom components.

- Consumer Electronics – Enclosures, connectors, and high-quality finishing.

- Automation & Industrial Equipment – Durable, reliable parts for demanding environments.

Why Choose GD Prototyping?

- End-to-End Project Management – From design validation to final assembly.

- Speed & Flexibility – Rapid turnaround times without sacrificing precision.

- Scalable Solutions – Supporting one-off prototypes, small-batch runs, and mass production.

- Engineering Excellence – A skilled team committed to innovation and quality.

- Global Trust – Reliable partner for companies worldwide.

At GD Prototyping, we believe that great products start with great processes. By offering comprehensive prototyping manufacturing services, we help our clients reduce time to market, cut costs, and gain a competitive edge. With the perfect balance of technology, expertise, and customer commitment, we are your trusted partner for high-quality manufacturing and product realization.