6061‑T6 vs 7075‑T6 for CNC Prototypes: A Complete Guide

Aluminum is a top choice for CNC machined prototypes and production parts. It offers an excellent combination of strength, light weight, and machinability. However, "aluminum" is not a single material. It is a family of diverse alloys, each with unique properties. For engineers and product designers, choosing the right alloy is a critical decision. This choice directly impacts a prototype's performance, durability, and cost. Among the most popular options are 6061-T6 and 7075-T6.

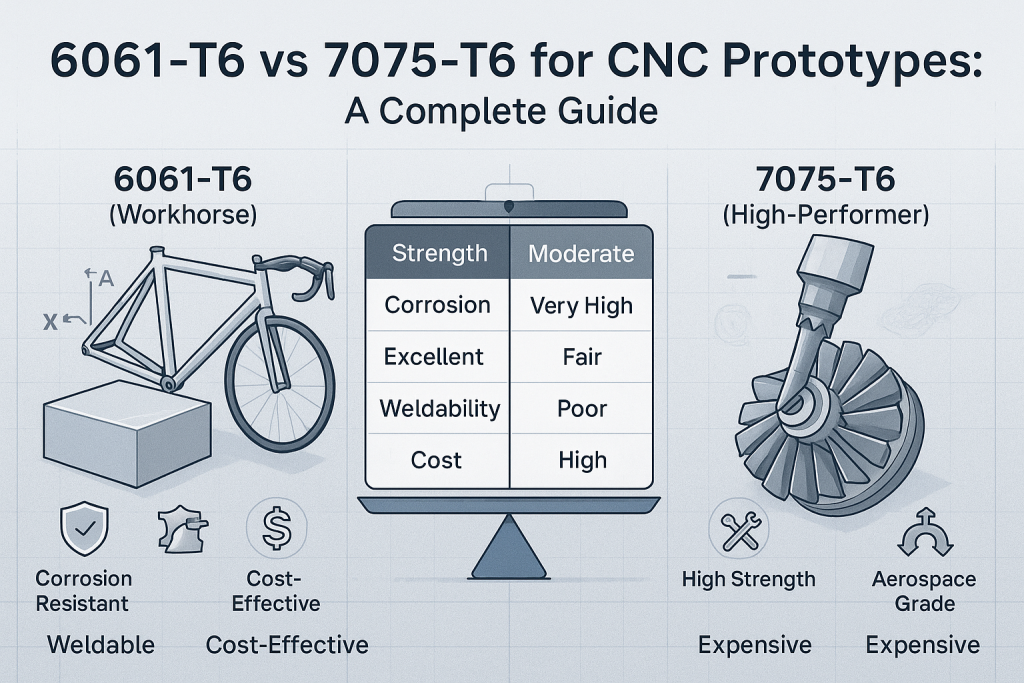

The primary difference between 6061-T6 and 7075-T6 aluminum is that 7075-T6 offers significantly higher strength and hardness, similar to steel, while 6061-T6 provides better weldability, superior corrosion resistance, and a lower overall cost. Understanding the nuanced trade-offs between these two alloys is key to successful component design.

As an expert CNC machining service, GD-Prototyping has extensive experience with both materials. We have machined thousands of prototypes from both 6061 and 7075 aluminum. This guide provides a deep, data-driven comparison. It will help you make an informed decision for your next project. This choice is a key step in any professional Rapid Prototyping Guide.

Understanding the Basics: Aluminum Alloys and the T6 Temper

Before comparing the two alloys, it is important to understand the nomenclature. The names "6061-T6" and "7075-T6" contain vital information about the material's composition and condition.

What Do "6061" and "7075" Mean?

Aluminum alloys are identified by a four-digit number. This system, established by the Aluminum Association, provides clues about the primary alloying elements mixed with the base aluminum.

- 6xxx Series: The principal alloying elements are magnesium and silicon. These alloys are known for good formability, weldability, and corrosion resistance. 6061 is the most common alloy in this series.

- 7xxx Series: The principal alloying element is zinc. These alloys are known for having the highest strengths of all aluminum series. They are often referred to as "aerospace grade." 7075 is the most common and well-known alloy in this high-performance series.

What is the "-T6" Temper?

The suffix "-T6" refers to the temper, or the heat treatment process, that the aluminum has undergone. The T6 temper is a two-stage process that significantly increases the material's strength.

- Solution Heat Treatment: The aluminum is heated to a high temperature (around 530°C for 6061). This dissolves the alloying elements into a solid solution, much like dissolving sugar in water. It is then rapidly quenched, usually in water, to lock these elements in place.

- Artificial Aging (Precipitation Hardening): After quenching, the material is "aged" by reheating it to a lower temperature (around 175°C for 6061) and holding it there for a specific time. This causes the alloying elements to precipitate out of the solution as extremely fine, uniformly dispersed particles. These particles act as obstacles that impede internal crystal movement, dramatically increasing the material's strength and hardness.

The T6 temper is the most common temper for both 6061 and 7075 aluminum. It provides an optimal combination of strength, machinability, and stability.

A Deep Dive into Aluminum 6061-T6: The Workhorse

Aluminum 6061-T6 is arguably the most versatile and widely used aluminum alloy in the world. It is often considered the "workhorse" of structural aluminum due to its excellent all-around properties, good availability, and affordable cost.

What is 6061-T6 Aluminum?

6061-T6 is a precipitation-hardened aluminum alloy. It offers a fantastic balance of strength, corrosion resistance, and machinability. Its predictable and reliable performance makes it a default choice for a vast range of applications.

Chemical Composition

The properties of 6061 are derived from its specific blend of alloying elements.

- Magnesium (Mg): ~1.0%. Increases strength.

- Silicon (Si): ~0.6%. Lowers the melting point and improves castability. When combined with magnesium, it forms magnesium silicide (Mg₂Si), which is key to the T6 precipitation hardening process.

- Other elements: Small amounts of copper, chromium, and iron.

Key Mechanical Properties

- Yield Strength: ~276 MPa (40,000 psi)

- Ultimate Tensile Strength: ~310 MPa (45,000 psi)

- Hardness (Brinell): 95

- Density: 2.70 g/cm³ (0.0975 lb/in³)

Common Applications

The versatility of 6061-T6 makes it ubiquitous. Common uses include:

- Structural components for buildings and vehicles.

- Bicycle frames and components.

- Electronics enclosures and chassis.

- Hydraulic blocks and manifolds.

- Base plates and machine fixtures.

A Deep Dive into Aluminum 7075-T6: The High-Performer

Aluminum 7075-T6 is the benchmark for high-strength aluminum alloys. Its impressive strength-to-weight ratio, which approaches that of many steels, makes it the premier choice for applications where performance is the primary consideration.

What is 7075-T6 Aluminum?

7075-T6 is a high-performance, precipitation-hardened aluminum alloy. It is one of the strongest aluminum alloys commercially available. This exceptional strength comes with trade-offs in terms of cost, corrosion resistance, and weldability.

Chemical Composition

The defining characteristic of 7075 is its high zinc content.

- Zinc (Zn): ~5.6%. This is the primary alloying element responsible for its extremely high strength.

- Magnesium (Mg): ~2.5%.

- Copper (Cu): ~1.6%. Copper also contributes to strength but reduces the alloy's corrosion resistance.

- Other elements: Small amounts of chromium, silicon, and iron.

Key Mechanical Properties

- Yield Strength: ~503 MPa (73,000 psi)

- Ultimate Tensile Strength: ~572 MPa (83,000 psi)

- Hardness (Brinell): 150

- Density: 2.81 g/cm³ (0.102 lb/in³)

Common Applications

The high cost of 7075-T6 reserves its use for demanding applications.

- Aerospace structural components (wing spars, fuselage frames).

- High-performance automotive parts (gears, connecting rods).

- Molds for the plastics and tooling industry.

- High-end sporting goods (performance bicycle components, rock climbing gear).

- Military applications (firearms components).

The Head-to-Head Comparison: 6061-T6 vs. 7075-T6

While the individual descriptions are helpful, a direct, side-by-side comparison provides the clearest picture. This table summarizes the key differences that engineers and designers must consider when selecting an alloy for their CNC prototypes.

| Property | Aluminum 6061-T6 (The Workhorse) | Aluminum 7075-T6 (The High-Performer) |

| Yield Strength | ~276 MPa (40 ksi) | ~503 MPa (73 ksi) |

| Ultimate Tensile Strength | ~310 MPa (45 ksi) | ~572 MPa (83 ksi) |

| Hardness (Brinell) | 95 | 150 |

| Machinability | Good | Excellent |

| Corrosion Resistance | Excellent | Fair to Good |

| Weldability | Excellent | Poor (Not Recommended) |

| Finishing (Anodizing) | Excellent (Clear, consistent finish) | Excellent (Slightly more yellowish/golden tint) |

| Cost | $ (Baseline) | $$$ (Significantly more expensive) |

An In-Depth Analysis of Key Differences

The comparison table provides the data. This section explains the practical implications of that data for CNC machining and product design.

Strength and Hardness: Where 7075 Excels

This is the most significant difference. 7075-T6 has a yield strength that is nearly double that of 6061-T6. Its strength-to-weight ratio is outstanding, approaching that of many common steels but at only one-third of the weight. For prototypes that will be subjected to high stress, high loads, or significant wear, 7075-T6 is the clear choice. Its superior hardness also means it will resist scratching and deformation much more effectively than 6061-T6.

Machinability: A Subtle but Important Difference

Both alloys are considered to have good machinability. However, machinists often prefer working with 7075-T6. Because it is harder and more brittle, 7075 tends to produce small, broken chips during CNC machining. This chip breakage is desirable as it prevents long, stringy chips from wrapping around the cutting tool. 6061-T6 is slightly softer and more "gummy," which can sometimes lead to longer chips. However, with modern tooling and proper feeds and speeds, both materials can be machined to an excellent surface finish.

Corrosion Resistance: The Advantage of 6061

6061-T6 exhibits excellent resistance to corrosion in most environments. Its magnesium and silicon alloying elements do not negatively impact its ability to form a stable, protective oxide layer. In contrast, the high copper content in 7075-T6 makes it more susceptible to corrosion, particularly stress-corrosion cracking (SCC) in harsh environments like saltwater. For prototypes that will be used outdoors or in marine applications without a protective coating, 6061-T6 is a much safer choice.

Weldability: The Clear Winner is 6061

6061-T6 is considered one of the most weldable heat-treatable aluminum alloys. It can be easily joined using standard TIG or MIG welding techniques, producing strong and reliable welds. On the other hand, 7075-T6 is generally considered unweldable for structural applications. The heat from welding ruins the T6 heat treatment, significantly weakening the material in the heat-affected zone and making it prone to cracking. If your prototype design requires welding, 6061-T6 is the only viable option between the two.

Finishing Characteristics: How They Take Anodizing

Both alloys are excellent candidates for finishing processes like anodizing. Anodizing creates a hard, ceramic-like oxide layer that improves corrosion and wear resistance. However, they can produce slightly different cosmetic results.

- 6061-T6 typically produces a very clear and aesthetically pleasing finish after standard anodizing.

- 7075-T6, due to its higher copper content, can sometimes have a slightly more yellowish or golden tint after clear anodizing. Both alloys can be dyed to a wide range of colors. The choice between Anodizing Type II vs Type III is critical. Type II provides a good cosmetic finish, while Type III (hardcoat) creates an extremely hard, wear-resistant surface suitable for demanding applications. For parts that require electrical conductivity and corrosion protection, the discussion of Alodine vs Anodize becomes essential.

Cost: The Deciding Factor for Many Prototypes

For most projects, cost is a major consideration. 7075-T6 is significantly more expensive than 6061-T6. The raw material cost can be two to three times higher. While its machinability is slightly better, this rarely translates into a significant reduction in machining time to offset the high material price. For prototypes where the extreme strength of 7075 is not a strict requirement, 6061 offers a much more economical path.

The Deciding Factor: How to Choose the Right Alloy for Your CNC Prototype

The best alloy is the one that meets your project's specific requirements without over-engineering. Use this simple guide to make your decision.

When Should You Choose 6061-T6?

Choose the workhorse, 6061-T6, when your prototype requires:

- Good to great strength, but not the absolute maximum.

- A high degree of corrosion resistance without a coating.

- A design that involves welding.

- A tight budget where cost is a primary driver.

- A general-purpose structural or electronic application.

When Should You Choose 7075-T6?

Choose the high-performer, 7075-T6, when your prototype requires:

- The highest possible strength-to-weight ratio.

- The application involves extreme stress, load, or wear.

- The component absolutely must not fail under load (e.g., aerospace).

- The design does not require any welding.

- Performance is the primary driver, and the budget can accommodate the higher material cost.

Conclusion

The choice between 6061-T6 and 7075-T6 aluminum is a classic engineering trade-off. 6061-T6 is the versatile, reliable, and cost-effective workhorse, suitable for a massive range of prototyping and production applications. 7075-T6 is the high-strength, high-performance specialist, reserved for the most demanding jobs where its superior mechanical properties are a strict requirement.

Understanding the strengths and weaknesses of each alloy is the key to designing parts that are both effective and economical. At GD-Prototyping, our team of experts has deep experience in CNC machining both of these materials. We can provide the guidance and manufacturing excellence needed to bring your designs to life, no matter which alloy you choose.