5‑Axis vs 3‑Axis CNC Machining: When to Choose

CNC machining stands as a cornerstone of modern manufacturing. It creates precise, high-quality parts from a solid block of material. Yet, not all CNC machines are created equal. The most fundamental distinction lies in the number of axes a machine can utilize. For engineers, designers, and project managers, understanding the difference between 3-axis and 5-axis CNC machining is critical. This choice directly influences a part's design, accuracy, surface finish, and final cost.

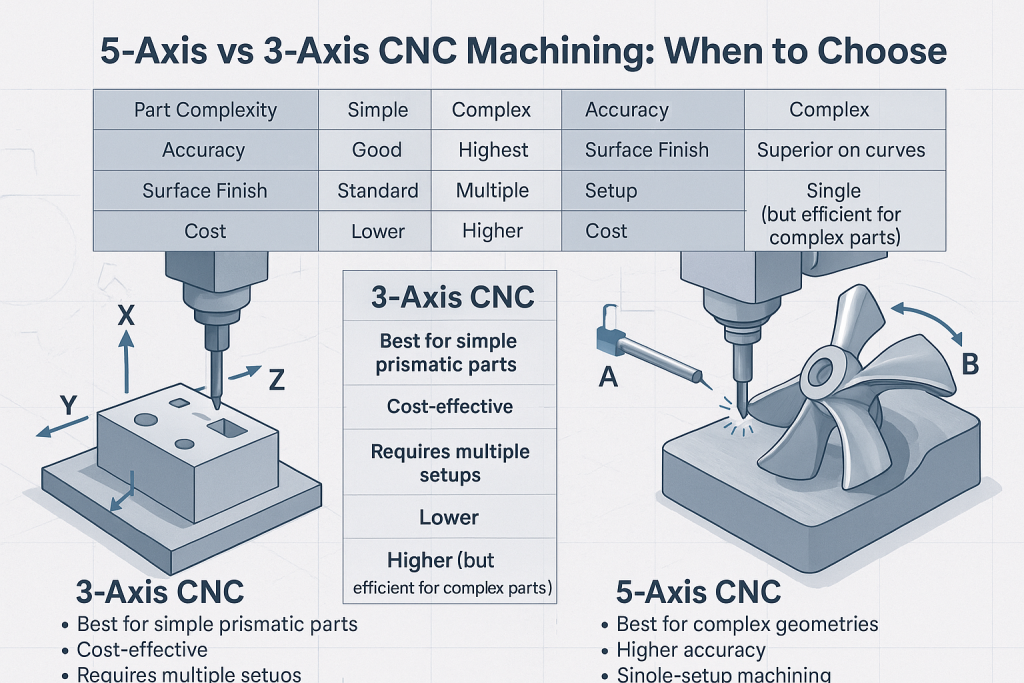

The primary difference is that 3-axis CNC machines move the cutting tool along three linear axes (X, Y, Z), while 5-axis machines add two rotational axes (A and B/C), allowing the tool to approach the workpiece from any angle. This added mobility unlocks the ability to create far more complex geometries in a single setup, but it comes with its own set of considerations.

As an expert service provider with a full suite of both 3-axis and 5-axis CNC capabilities, GD-Prototyping has deep, hands-on experience with both technologies. This guide provides a comprehensive comparison to help you determine which process is the right choice for your specific project.

Understanding 3-Axis CNC Machining: The Foundation

Three-axis CNC machining is the most common and widely understood form of the technology. It is a powerful and cost-effective method for producing a vast range of components. Its operation is straightforward and forms the basis for all other multi-axis machining.

How Does a 3-Axis CNC Machine Work?

A 3-axis machine operates along three linear axes. Imagine the corner of a box to visualize this movement.

- X-axis: Left to right movement.

- Y-axis: Front to back movement.

- Z-axis: Up and down movement.

The workpiece is fixed to the machine's bed. The cutting tool, held in a rotating spindle, moves along these three axes to remove material. The tool always maintains a fixed orientation relative to the workpiece. This approach is highly effective for machining features on a single face of a part.

What Geometries is 3-Axis Machining Best For?

Three-axis machining excels at producing prismatic parts. These are components defined by flat faces and straight edges, though they can also include simple curves. Common applications include:

- Drilling and Tapping Holes: Creating precise, perpendicular holes.

- Milling Pockets and Slots: Machining out cavities and channels.

- Cutting Profiles: Shaping the outer perimeter of a part.

- Facing Operations: Creating a perfectly flat top surface.

For parts where the majority of features can be accessed from a single direction, 3-axis machining is the most efficient and economical choice.

The Concept of Multiple Setups

The primary limitation of 3-axis machining is tool access. Since the cutting tool can only approach the part from one direction at a time, machining features on other sides requires a manual intervention. To machine a feature on the side of a cube, for example, the operator must:

- Stop the machine.

- Unclamp the workpiece.

- Manually rotate the part 90 degrees.

- Carefully re-clamp and re-align the part.

- Begin a new machining program.

This process is called a "setup." A part that requires machining on all six sides will need at least six separate setups. Each setup adds significant labor time and, more importantly, introduces a small chance of alignment error.

Understanding 5-Axis CNC Machining: The Advanced Solution

Five-axis CNC machining represents a significant leap forward in manufacturing capability. By adding two rotational axes, these machines can create incredibly complex parts with unparalleled precision and efficiency.

How Does a 5-Axis CNC Machine Work?

A 5-axis machine builds upon the three linear axes (X, Y, Z) by adding two rotational axes. These are typically designated as:

- A-axis: Rotation around the X-axis.

- B-axis: Rotation around the Y-axis.

- C-axis: Rotation around the Z-axis.

A 5-axis machine will use two of these three rotational axes. The specific combination depends on the machine's configuration.

Types of 5-Axis Machines

There are two primary configurations for 5-axis machines, which achieve the rotational movements in different ways.

- Trunnion Style: The machine bed itself, which holds the workpiece, tilts and rotates. This is common for smaller to medium-sized machines.

- Swivel-Rotate Head Style: The workpiece remains stationary while the machine's head, which holds the cutting tool, swivels and rotates around the part. This is typical for larger machines used for massive components.

The Power of Single-Setup Machining (3+2 vs. Continuous 5-Axis)

The greatest advantage of 5-axis technology is the ability to machine multiple sides of a part in a single setup. This is achieved in two primary ways:

- 3+2 Positional Machining: This is the most common use of a 5-axis machine. The machine uses the two rotational axes to orient the workpiece to a specific fixed angle. It then locks these axes and performs all machining operations using the standard three linear axes. This allows the machine to access five of the six sides of a cube without any manual setups, dramatically improving accuracy and reducing labor time.

- Continuous (or Simultaneous) 5-Axis Machining: This is the most advanced form of the technology. All five axes move at the same time in a coordinated, fluid motion. This allows the cutting tool to follow complex, organic contours and create the smooth, flowing surfaces seen in aerospace components, turbine blades, and advanced medical implants.

What Geometries Does 5-Axis Machining Enable?

Five-axis machining is the only way to efficiently produce parts with:

- Complex, Organic Contours: Such as those found in turbine blades or ergonomic medical devices.

- Deep Cavities with Sloped Walls: The tool can tilt to reach into deep pockets without the tool holder colliding with the workpiece.

- Undercuts and Off-Axis Features: Machining features that are not perpendicular to the main faces of the part.

A Head-to-Head Comparison: 3-Axis vs. 5-Axis

Choosing the right technology requires a clear understanding of the trade-offs between these two powerful manufacturing methods.

Part Complexity and Geometry

This is the most significant differentiator. 3-axis machining is ideal for simpler, prismatic parts. If the design largely consists of features on one or two parallel faces, 3-axis is sufficient. 5-axis machining is essential for parts with complex, organic surfaces, multiple angled features, and deep cavities that require the tool to approach from many different directions.

Speed and Efficiency

The answer here is nuanced. For a simple plate with a few holes, a 3-axis machine will be faster and more cost-effective. However, for a complex part that requires five setups on a 3-axis machine, a 5-axis machine will be vastly faster. By completing the part in a single setup, it eliminates all the time associated with manual re-clamping and re-alignment.

Accuracy and Repeatability

Every time a part is manually re-clamped in a 3-axis setup, a small amount of positioning error is introduced. While skilled machinists can minimize this, it is impossible to eliminate completely. For a part with features on multiple faces that have tight tolerances relative to each other, a 5-axis machine offers superior accuracy. By machining all features in a single clamping, it removes this source of error entirely.

Surface Finish

5-axis machining can produce a better surface finish on contoured surfaces. The machine can keep the cutting tool perfectly perpendicular to the surface at all times. This allows for the use of shorter, more rigid cutting tools, which reduces tool vibration and chatter. The result is a smoother, more accurate surface without the "scalloping" marks that can be left by 3-axis ball-end mills on curved surfaces.

Cost

Cost is a multi-faceted issue.

- Machine Cost: 3-axis machines are less complex and therefore less expensive to purchase and maintain.

- Programming Cost: Programming a simple 3-axis part is faster and requires less specialized software. Continuous 5-axis programming is highly complex and requires expert CAM programmers.

- Part Cost: For a simple part, the 3-axis machine will always be cheaper. For a highly complex part, the 5-axis machine can actually be cheaper. It avoids the significant labor costs of multiple setups and the need to create expensive custom fixtures to hold the part at odd angles.

Understanding these cost differences is key. Businesses can use a CNC Machining Cost Calculator to help estimate project expenses based on complexity and material.

The Decision Framework: A Use-Case Matrix

To simplify the decision, this matrix provides a clear guide for when to choose each technology based on common project characteristics.

| Use Case / Part Characteristic | Best Choice | Reason Why |

| Simple Prismatic Part (e.g., base plate, bracket with perpendicular holes) | 3-Axis | Most cost-effective. No need for rotational axes. All features accessible from one or two setups. |

| Part with Multiple Setups (e.g., housing with features on 5 sides) | 5-Axis (3+2) | Eliminates manual setups, drastically improving accuracy and reducing labor costs. |

| Complex Organic Contours (e.g., turbine blade, ergonomic grip) | 5-Axis (Continuous) | The only way to efficiently produce smooth, complex, and flowing surfaces. |

| Deep Pockets with Sloped Walls | 5-Axis | The tool can tilt to reach deep areas without the holder colliding with the part. Enables shorter, more rigid tools. |

| High-Volume Production of Simple Parts | 3-Axis | Lower cycle time and machine cost make it the most economical choice for mass production. |

| Low-Volume, High-Complexity Prototypes | 5-Axis | Avoids the high cost of creating multiple custom fixtures required for a 3-axis machine. |

| Tightest Positional Tolerances | 5-Axis | Single-setup machining removes the risk of re-clamping errors, ensuring the highest accuracy between features. |

Beyond CNC: Considering Other Technologies

While CNC machining is incredibly versatile, it is not always the optimal solution for every part. For prototypes with extremely complex internal features or lightweight lattice structures, additive manufacturing technologies can sometimes offer a better solution.

For example, creating a part with intricate, curved internal cooling channels is nearly impossible with any form of subtractive machining. In these specific cases, technologies like Direct Metal Laser Sintering (DMLS) can be superior. It is important for designers to understand the full landscape of available technologies. You can learn more in our detailed DMLS vs CNC Machining guide.

Conclusion

The choice between 3-axis and 5-axis CNC machining is a strategic decision that should be driven by the specific requirements of your part. It is not a question of which technology is "better," but rather which technology is the "right tool" for the job. 3-axis machining remains the cost-effective workhorse for a massive range of components. 5-axis machining provides the advanced capabilities needed for the most complex and high-precision parts.

By carefully considering a part's geometry, accuracy requirements, and budget, engineers can select the process that delivers the best possible outcome. At GD-Prototyping, our team of experts is equipped with both technologies and can provide the guidance needed to make the optimal choice for your project.