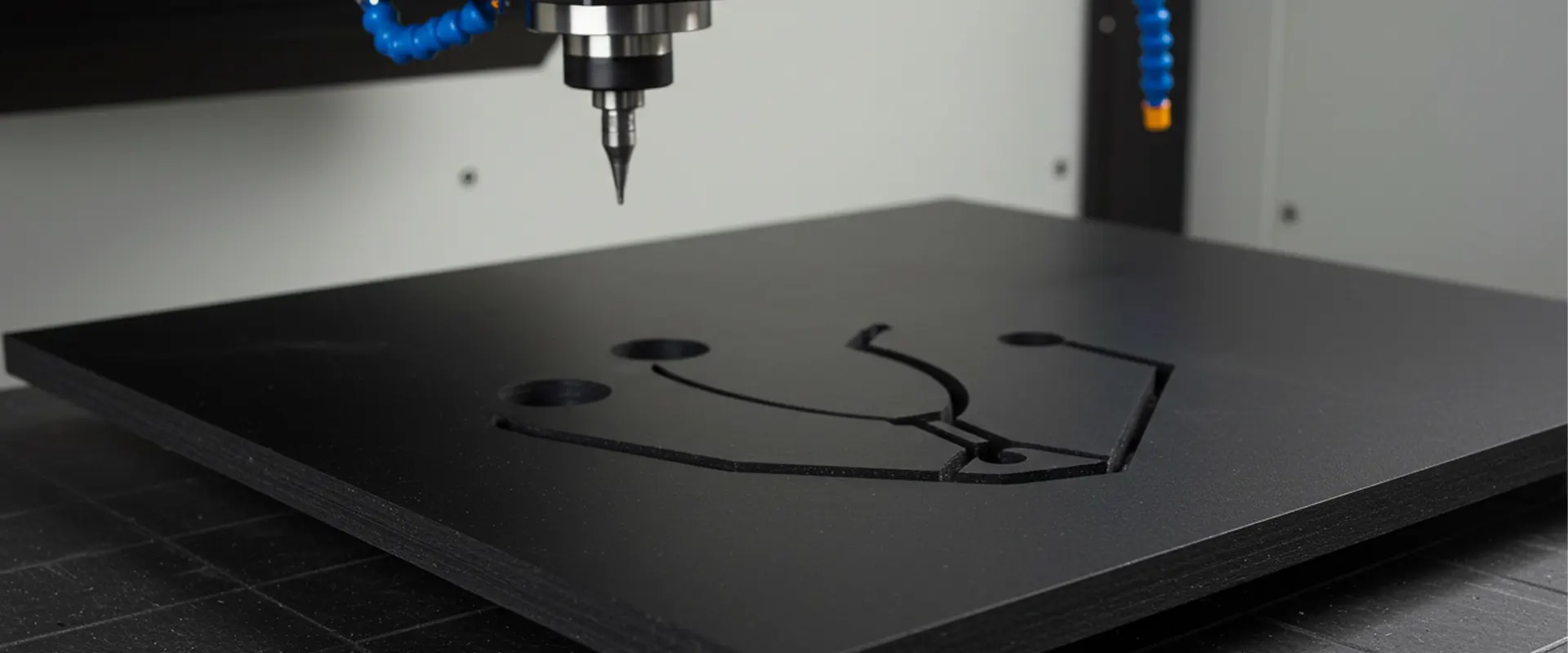

3D Printing

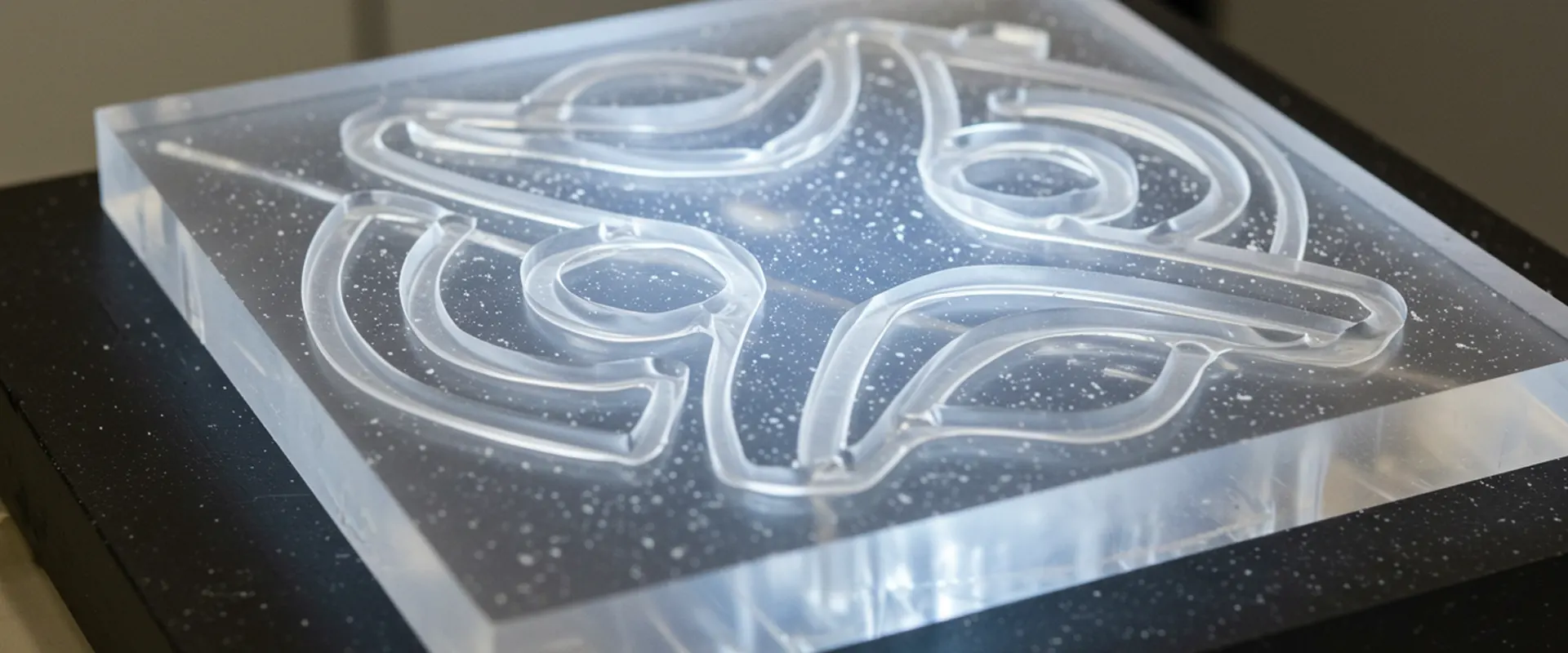

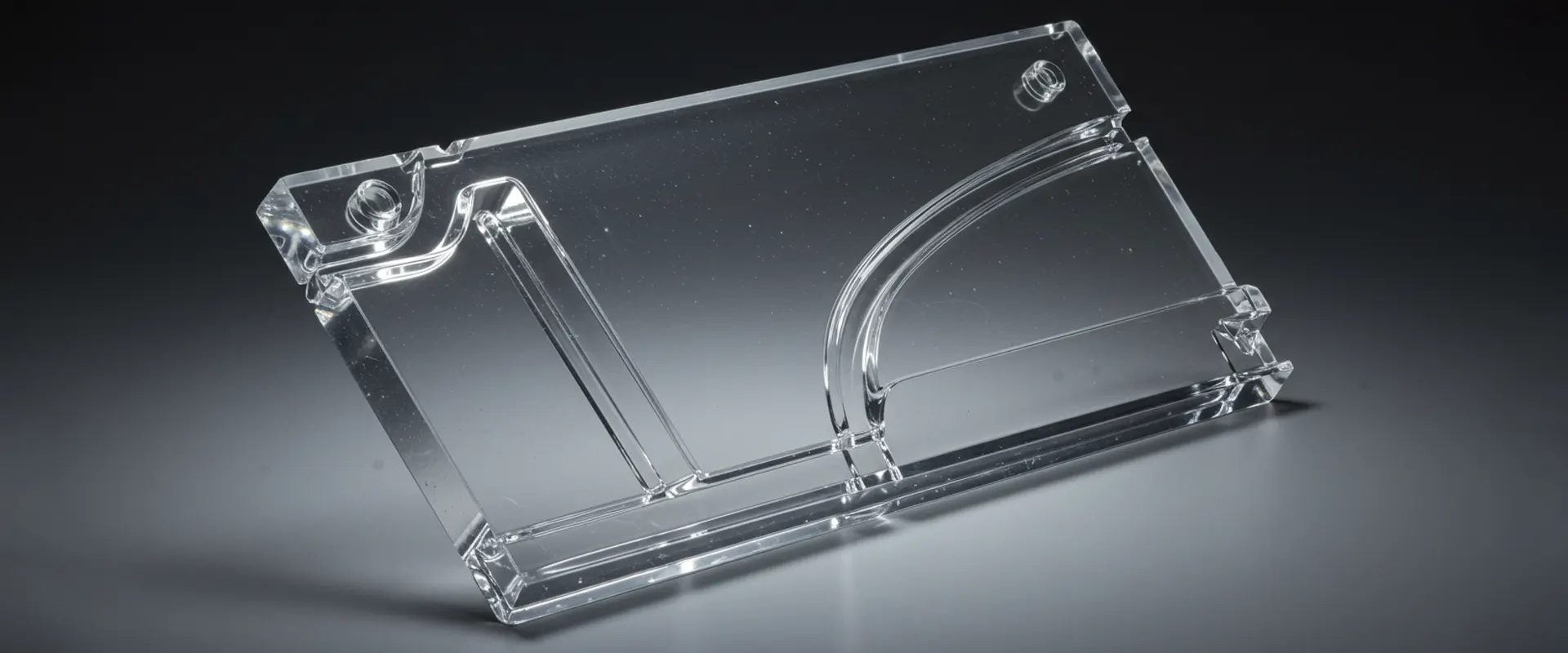

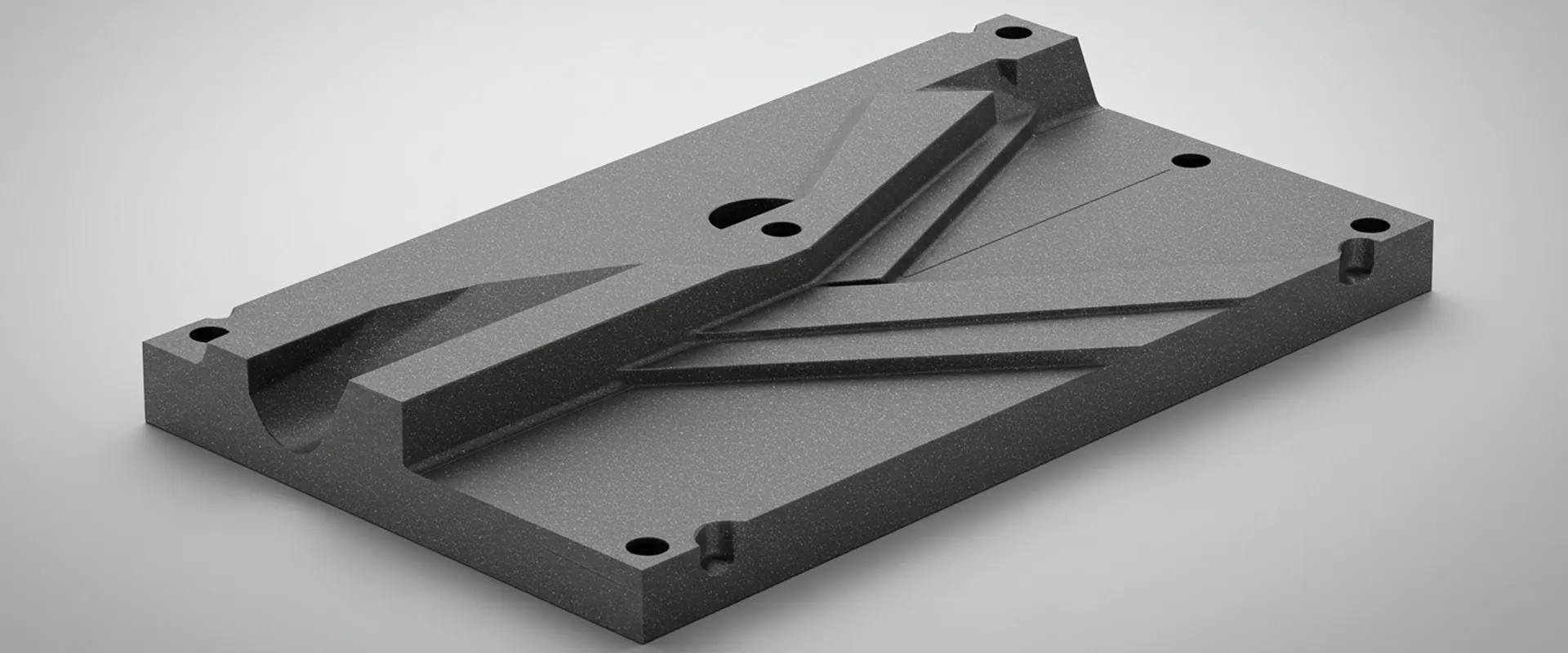

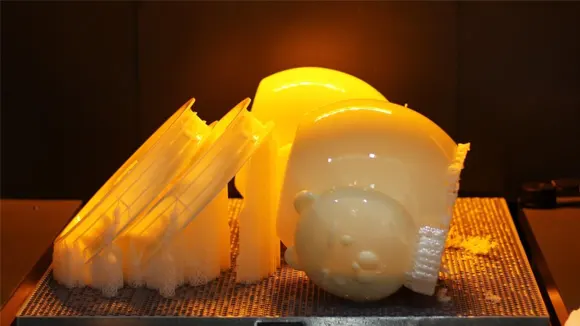

At GD Prototyping, we specialize in advanced 3D printing services that bring your ideas to life with unmatched speed and precision. Our 3D printing center offers multiple technologies including SLA, SLS, MJF, and DMLS, covering both plastic and metal materials. From rapid prototyping to small-batch production, our solutions deliver high accuracy, excellent surface quality, and durability for demanding applications.

-

Wide Material Selection: Compatible with both plastics and metals.

-

Fast Turnaround: Prototypes delivered within 1–2 days.

-

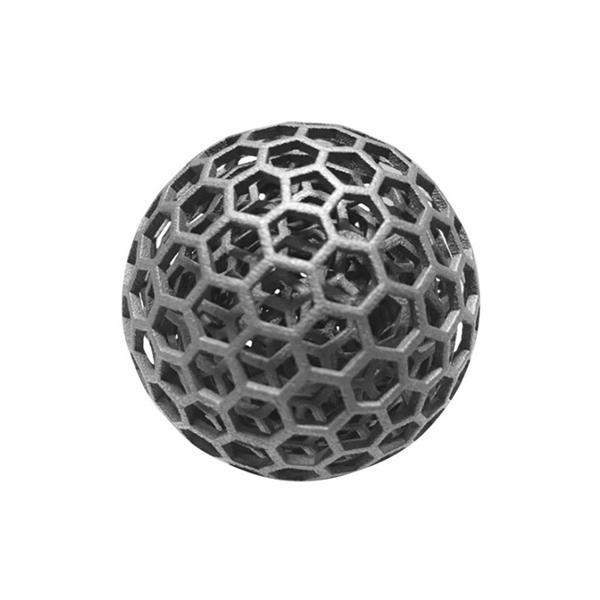

Design Flexibility: Easily produce complex shapes and geometries.

-

Cost-Effective: Minimized tooling and assembly expenses.

3D Printing Services

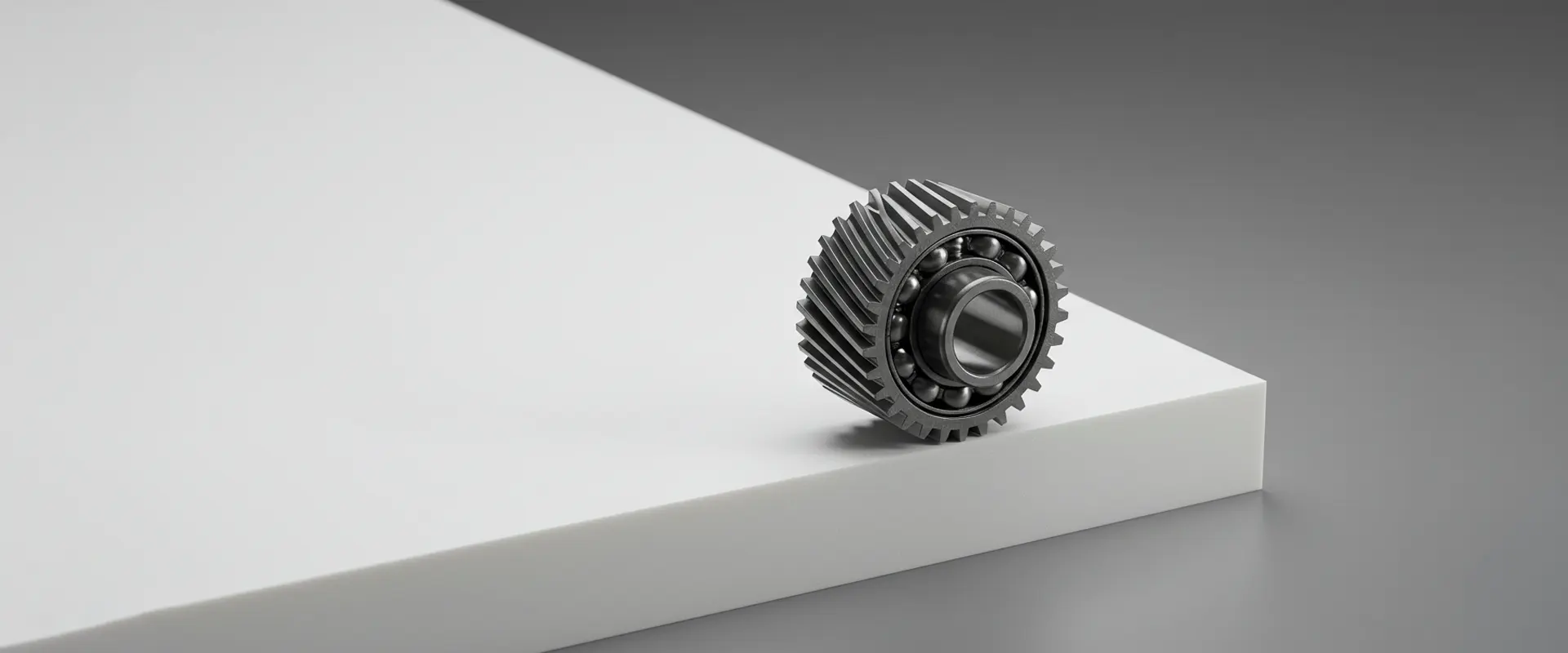

3D printing technologies like SLA, SLS, MJF, and SLM enable rapid, precise production of complex plastic and metal parts. These methods offer high design flexibility, fast turnaround, and cost-effective manufacturing for various industries including aerospace, medical, and prototyping.

Advantages of 3D Printing

Rapid & Cost-Effective

Parts ready in as little as 24 hours.

Versatile Applications

From visual models to functional production parts.

Complex Geometry

Intricate designs made without extra cost.

Durability

Impact-resistant, reliable, and dimensionally stable parts.

3D Printing Technical Information

These advanced 3D printing technologies offer precise, rapid manufacturing for various materials and complex designs. With quick lead times and high accuracy, they support prototyping and production needs efficiently.

| Technology | Working Platform Size (mm) | Maximum Build Size (mm) | Lead Time | Dimensional Accuracy | Layer Height |

| Stereolithography (SLA) | 1400 x 700 x 500 | Up to 1380 x 680 x 480 | From 3 business days | +0.5% with lower limit of +0.15 mm | 50 - 100 μm |

| MultiJet Fusion (MJF) | 400 x 320 x 400 | 380 x 285 x 380 | 3 business days | +0.3% with lower limit of ±0.3 mm | 80 μm |

| Selective Laser Sintering (SLS) | 360 x 360 x 600 | Up to 320 x 320 x 580 | From 3 business days | +0.3% with lower limit of ±0.3 mm | 80 μm |

| Direct Metal Laser Sintering (DMLS) | — | 200 x 200 x 300 | 7 business days | <10mm: +0.2% with lower limit of ±0.2 mm; >10mm: +2% | 30 μm |

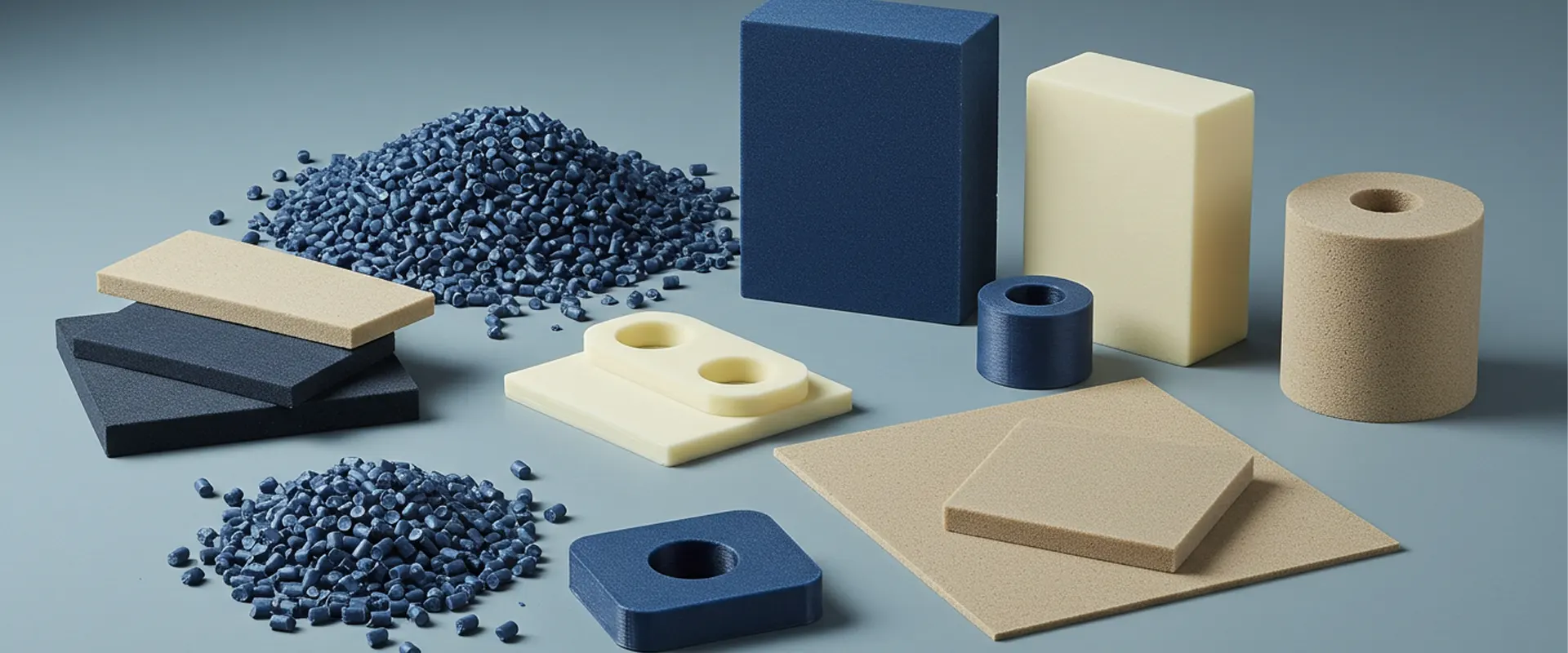

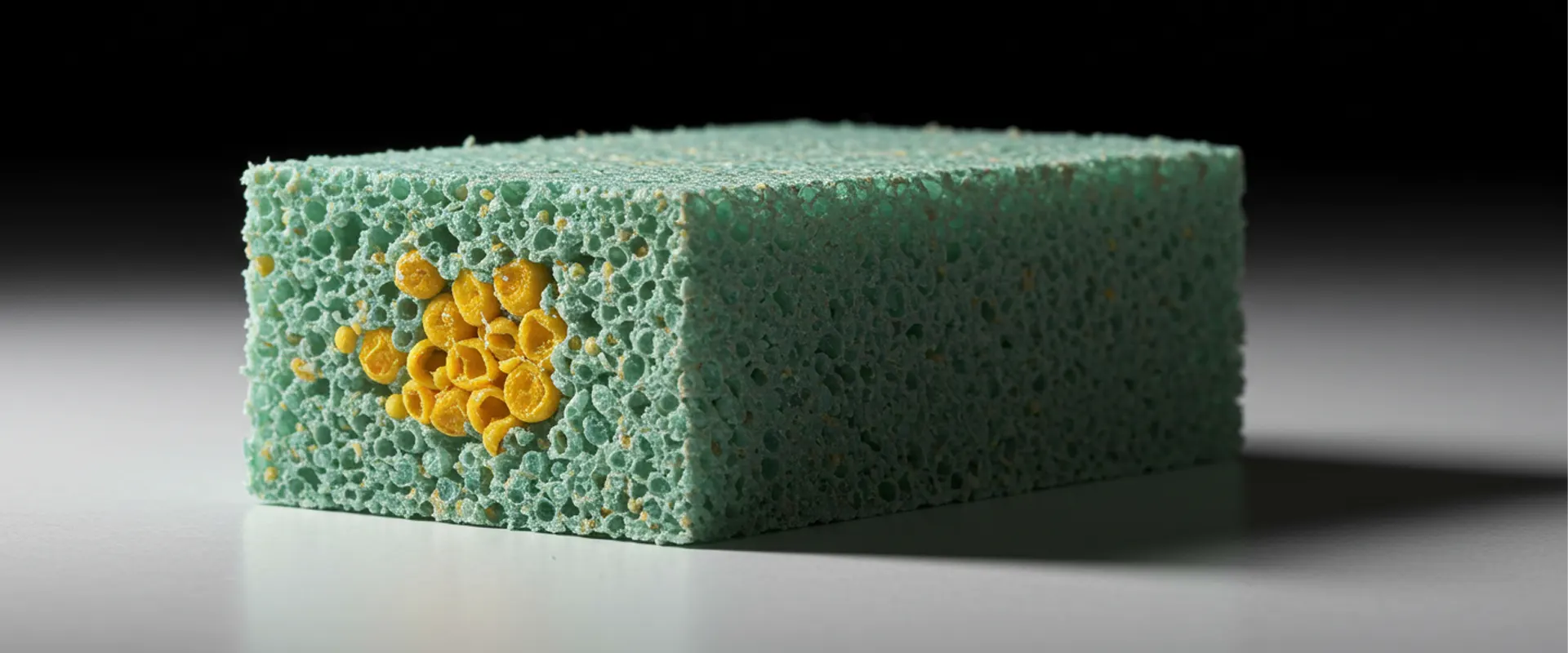

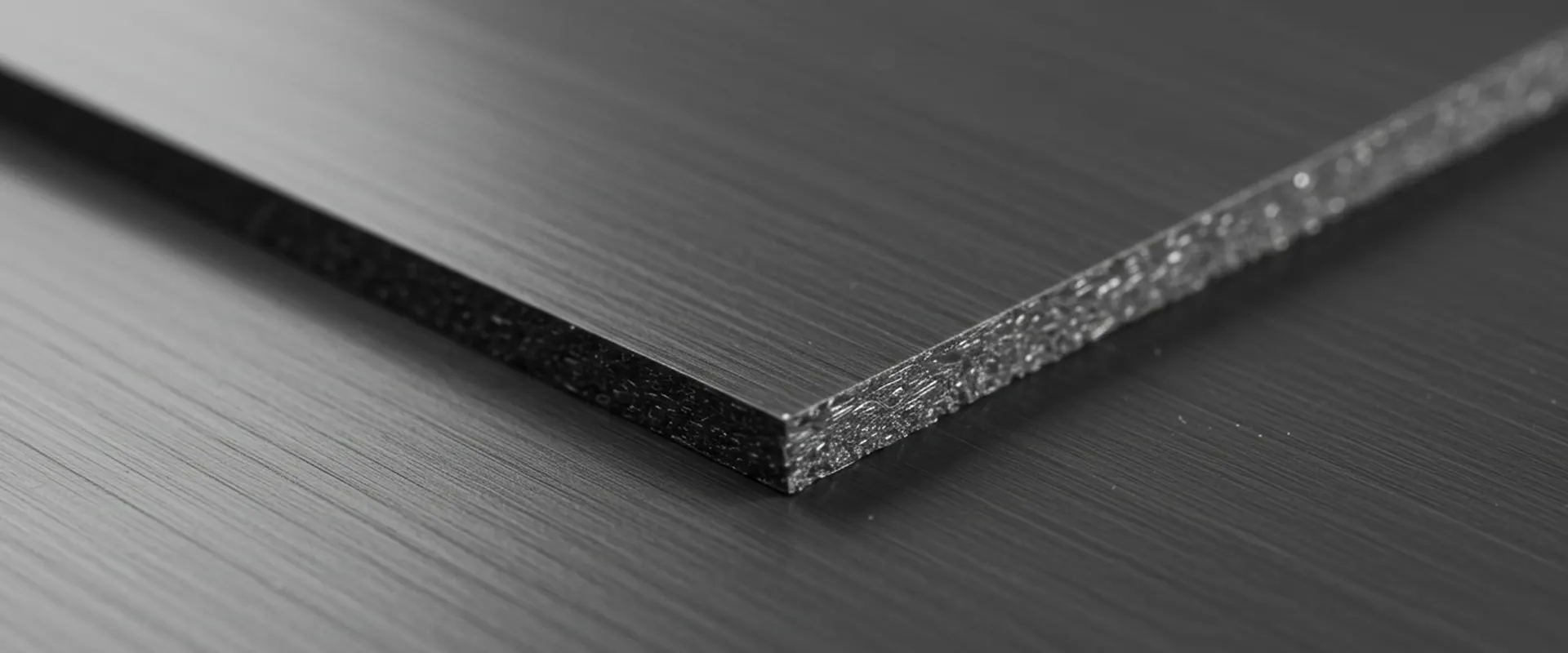

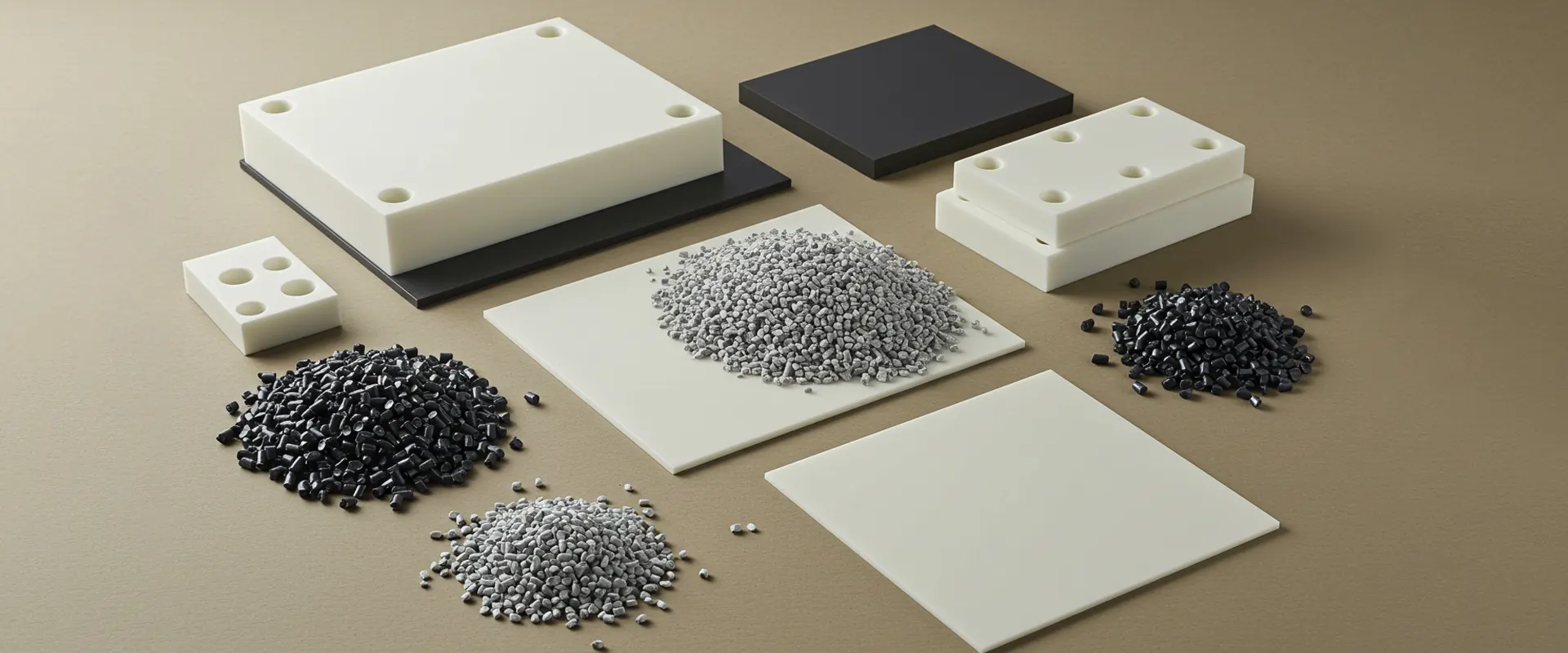

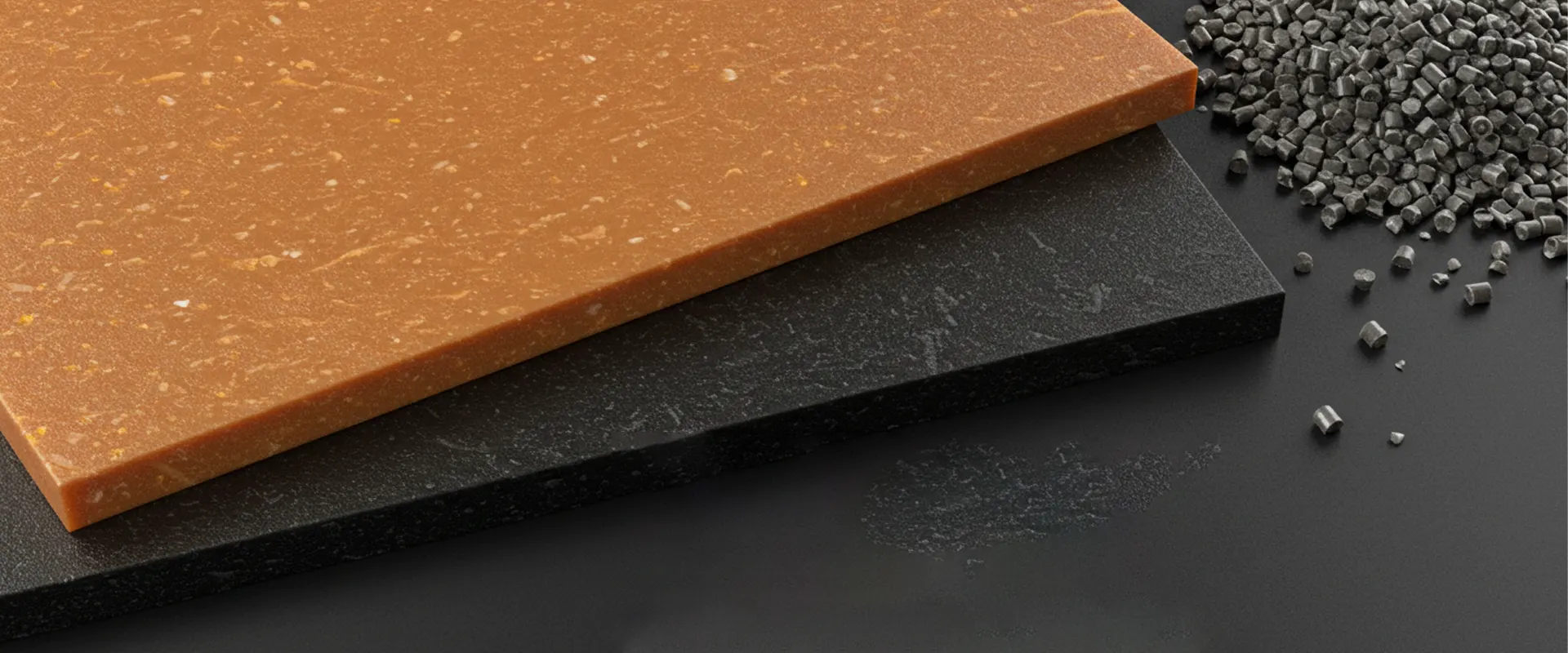

We support a wide variety of plastic and metal materials for both prototyping and production:

-

Plastics: ABS, PC, PP, Nylon (PA6/PA66), POM, PMMA, PEEK, PTFE, Flame-retardant ABS/PC, and more.

-

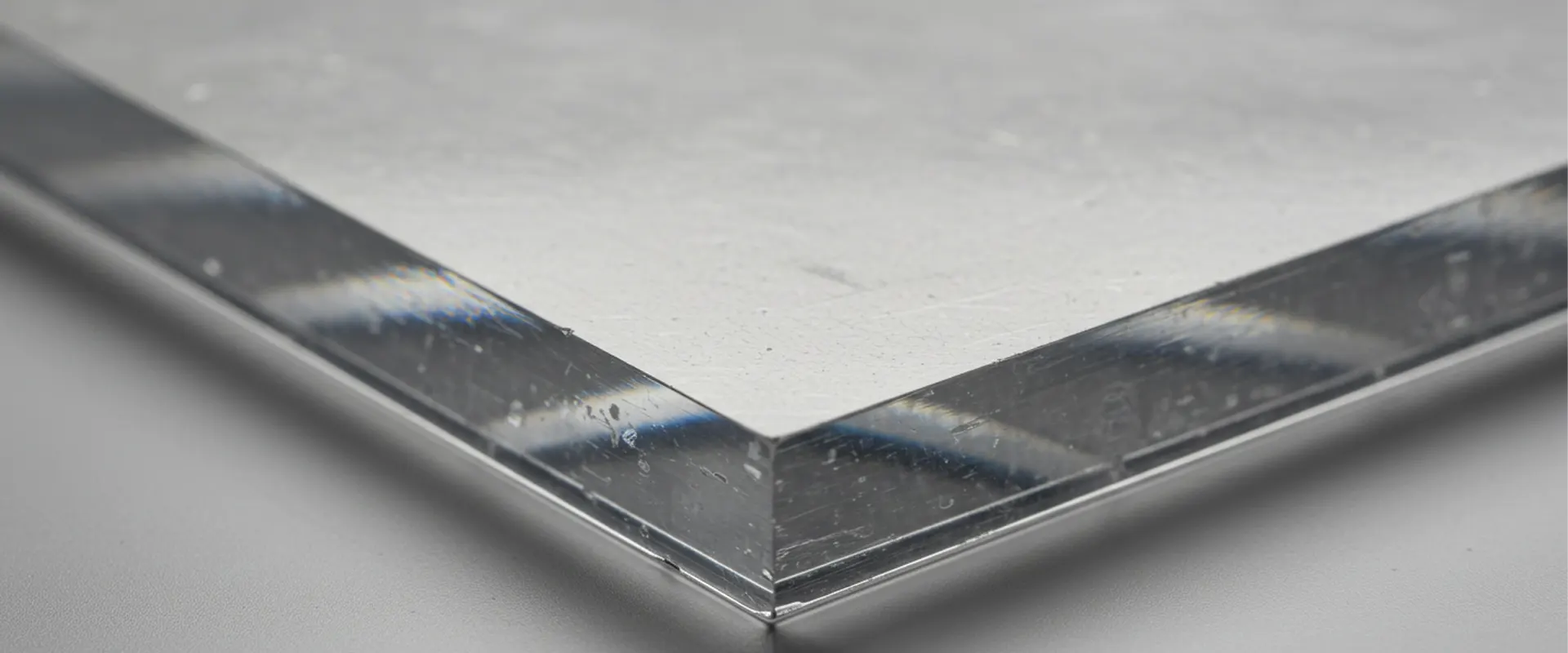

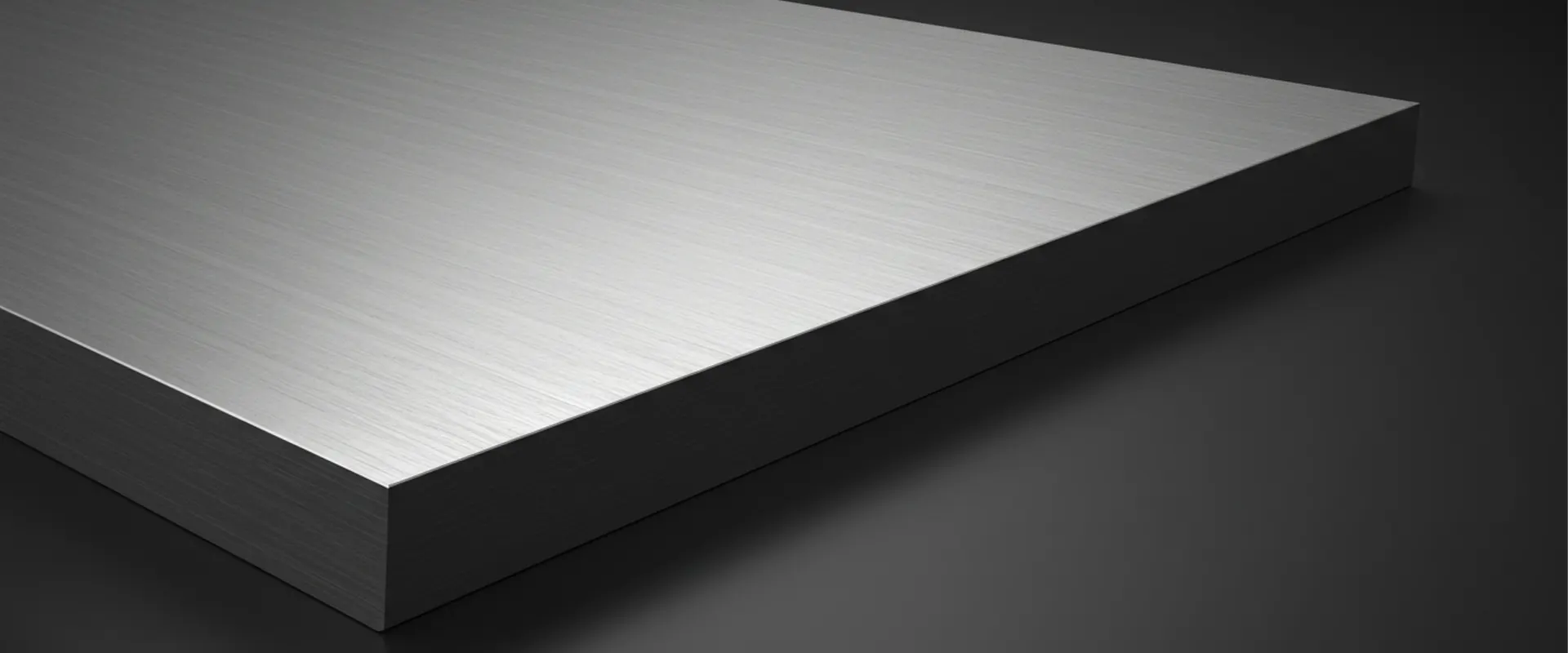

Metals: Aluminum alloys (6061, 2024, 7075, ADC12, etc.), Copper, Brass, Titanium, Magnesium, Zinc alloys, Alumina ceramic.

Custom material options available upon request.

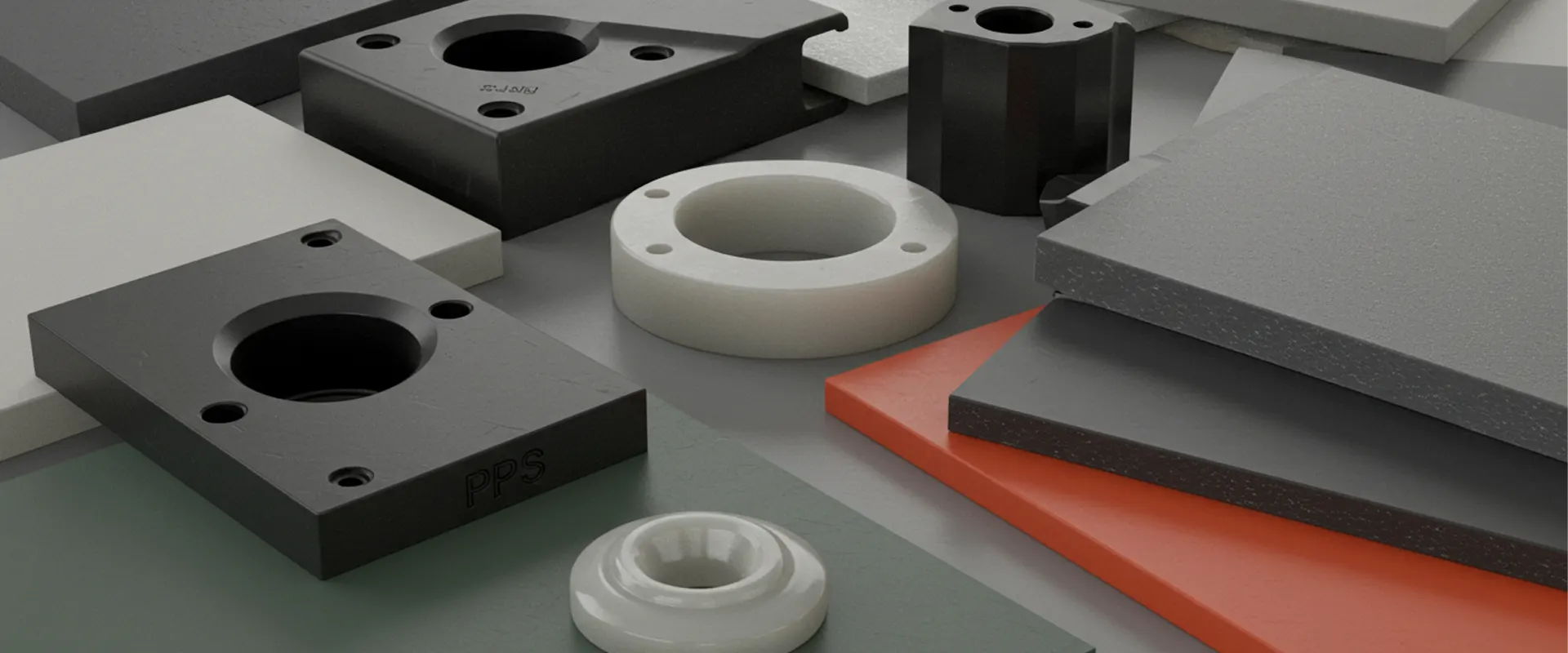

3D Printing Materials

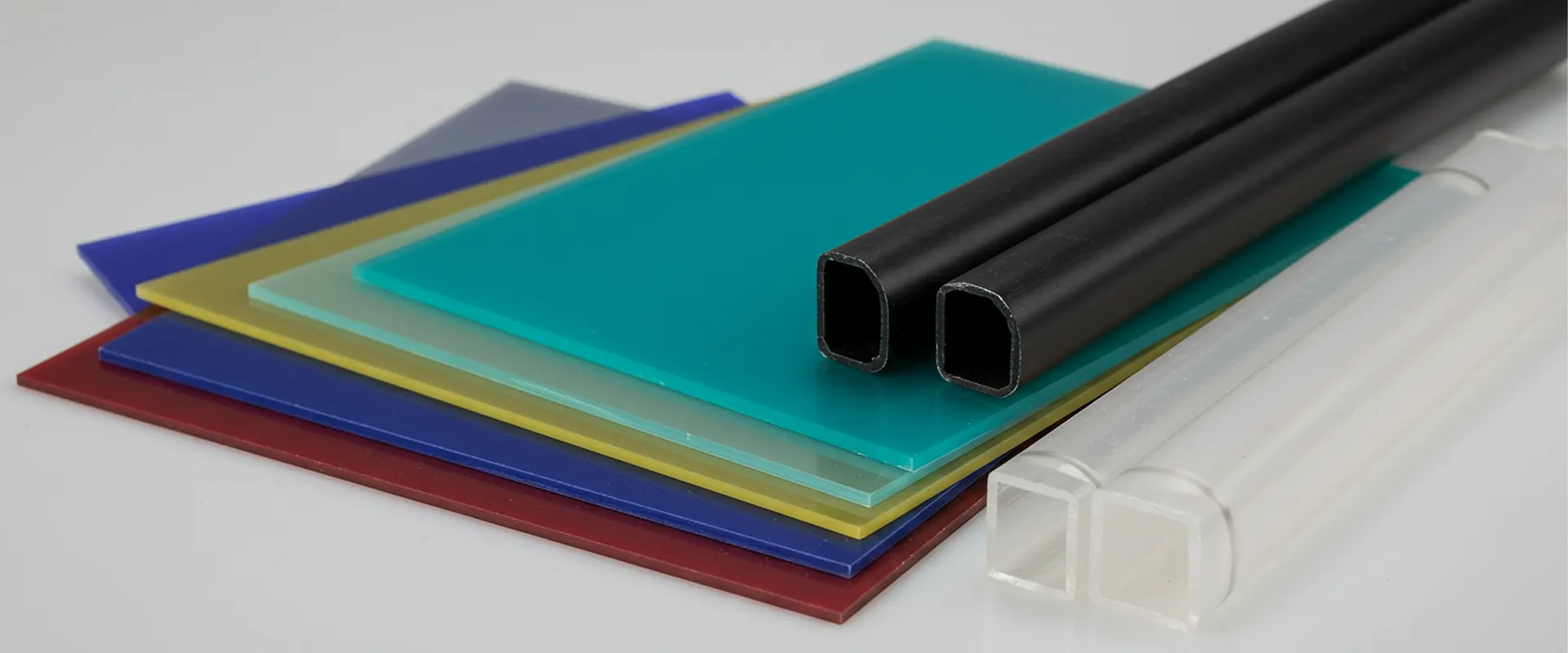

A variety of CNC machined metal and plastic part options are available for an instant online quote.

- ABS

- PMMA

- POM

- PP

- PC

- Nylon (PA6/PA66)

- ABS+PC

- PC+ABS

- Transparent ABS

- Flame-Retardant ABS

- Flame-Retardant PC

- Nylon+fiber PAFG+30%

- PC+GF30%

- PP+30%

- PTFE

- PEEK

- PPS

- PPE

- PPS+GF40%

- PES

- Epoxy Resin Sheet

- DSM351

- Synthetic wood

- Bakelite

- Brown PMMA

- MC Nylon White

- PVC

- PE

- Delrin (Acetal) Black

- Flame Retardant ABS

- Rigid PVC

- Anti-static ABS

- HDPE

- PA+GF45%

- HIPS

- Flame-Retardant PC+ABS

- PVC

- MC703

- POM (NW-02)

- Conductive POM

- PTFE

- Transparent Anti-static PVC

- PET

- UPE

- PVDF F2

- Synthetic wood

- White PVC

- Transparent PVC

- FR4

- Epoxy Resin

- Food-Grade PC

- POM-Delrin

- PA66+GF15%

- Black PEI

- White HDPE

- UHMWPE

- Black Copolymer Acetal

- Ultem 1000

- PVDF

- Antistatic PEEK

- Aluminum 6061

- Aluminum A5052

- ADC12

- LY12

- AL T6

- AL T51

- A1100

- Aluminum Alloy 2A12

- 2A12

- Alumina Ceramic

- Brass

- Copper(CU)

- Magnesium Alloy

- Zinc Alloy (Zn)

- Aluminum 3003

- Aluminum A5056

- A2017

- Copper Alloy C3604

- Aluminum Alloy 5000

- AL1070

- Aluminum Alloy AL2024 / A2024-T6

- Aluminum Alloys AL7075 / 7050 / 7451

- Imported Aluminum Alloy 5083

- Imported Aluminum Alloy 6082

- Imported Aluminum Alloy 7075

- Imported Aluminum Alloy 6061-T561

- AL1060

- 2A14

- C2801P-1/2H

- C1020P

- A7072

- A7000

- C1100

- A2014

- Aluminum Alloy 7000

- Titanium Alloy

- 7075

- A2011

- A2024

- A7050

- 11SMn30

- ABS

ABS

ABS is a common thermoplastic known for its toughness and impact resistance. It is available in various colors including gray-white, beige, and black.

Color:

Gray-white, Beige, Black

Density:

1.2 g/cm³

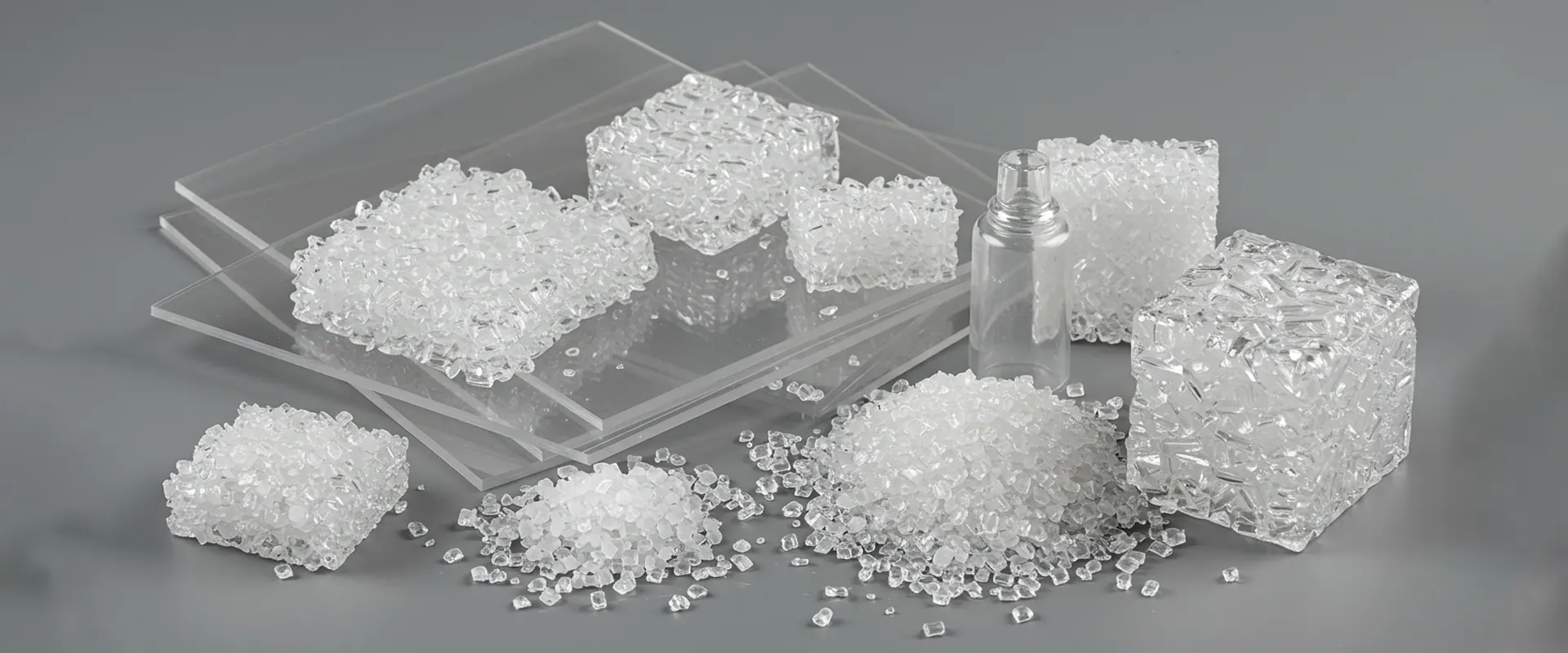

- PMMA

PMMA

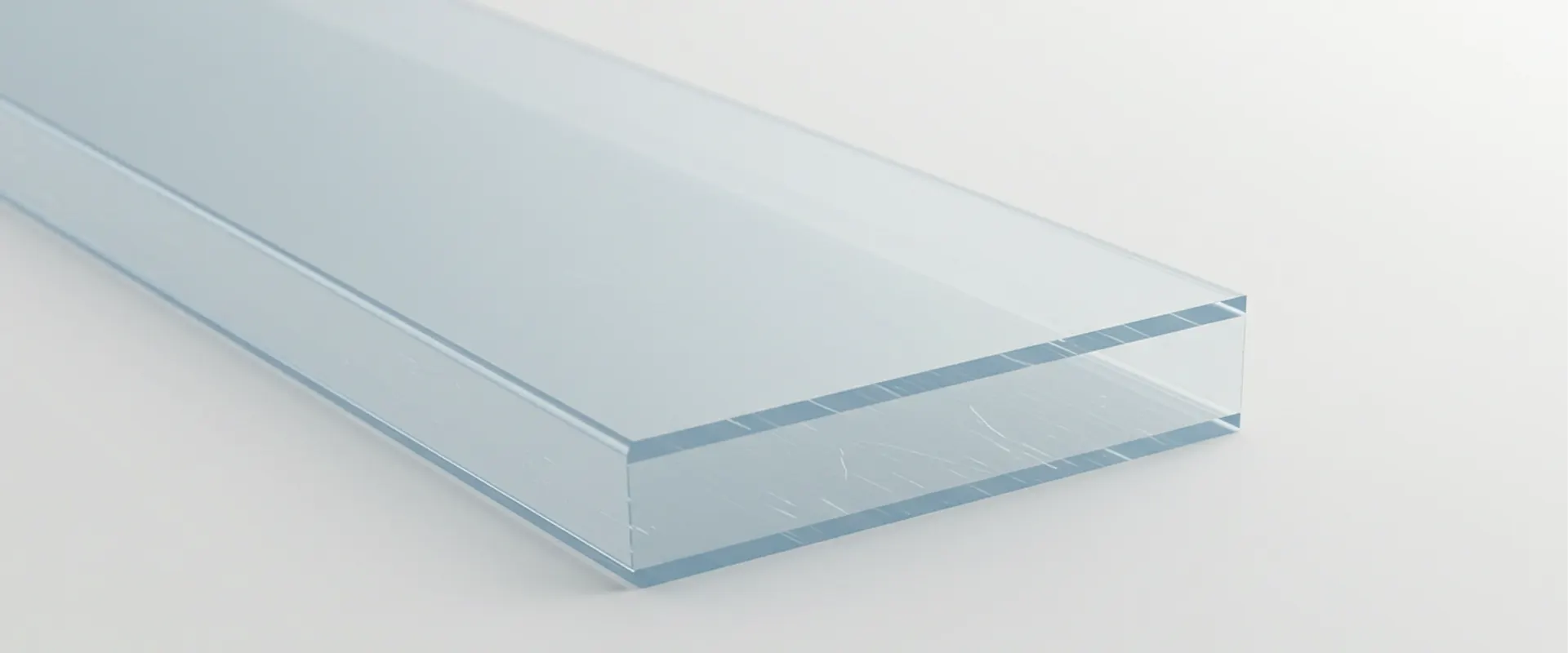

PMMA, also known as acrylic, is a transparent thermoplastic with excellent optical clarity and weather resistance.

Color:

Transparent

Density:

1.2 g/cm³

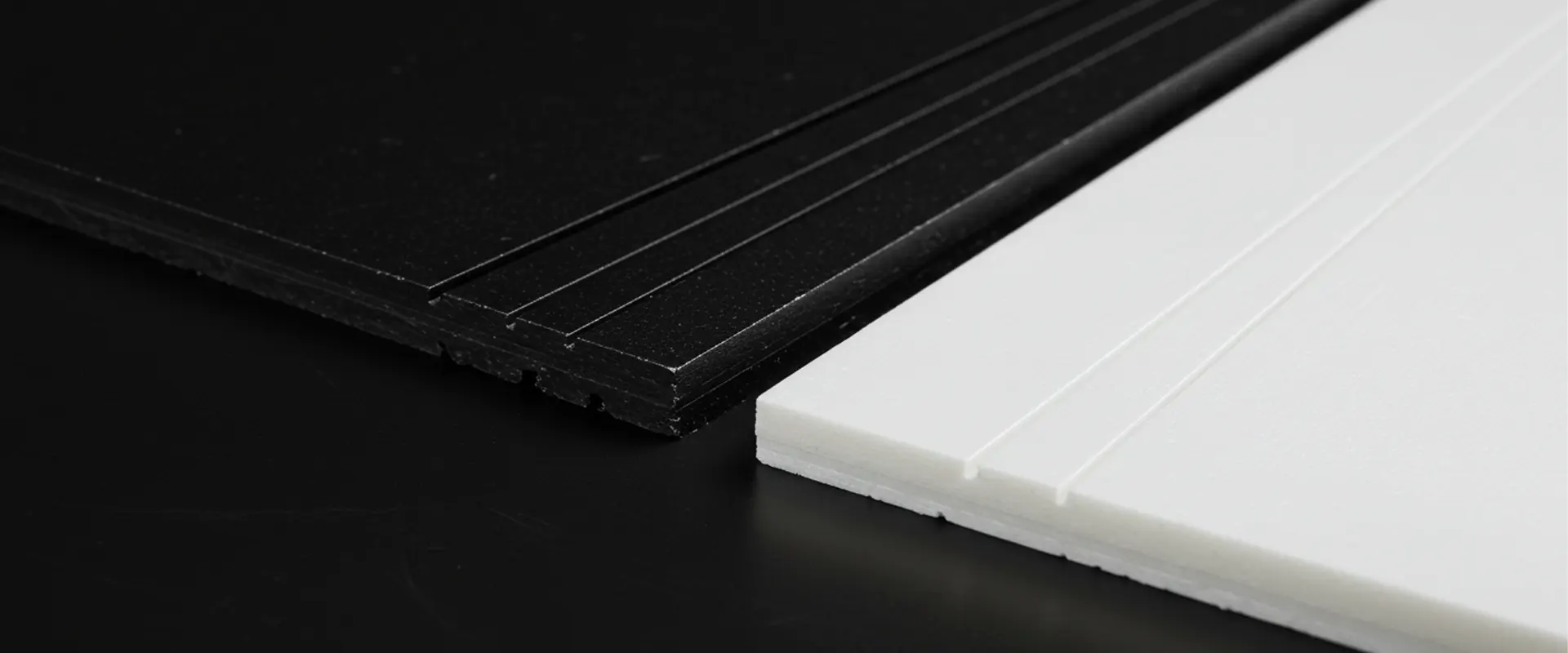

- POM

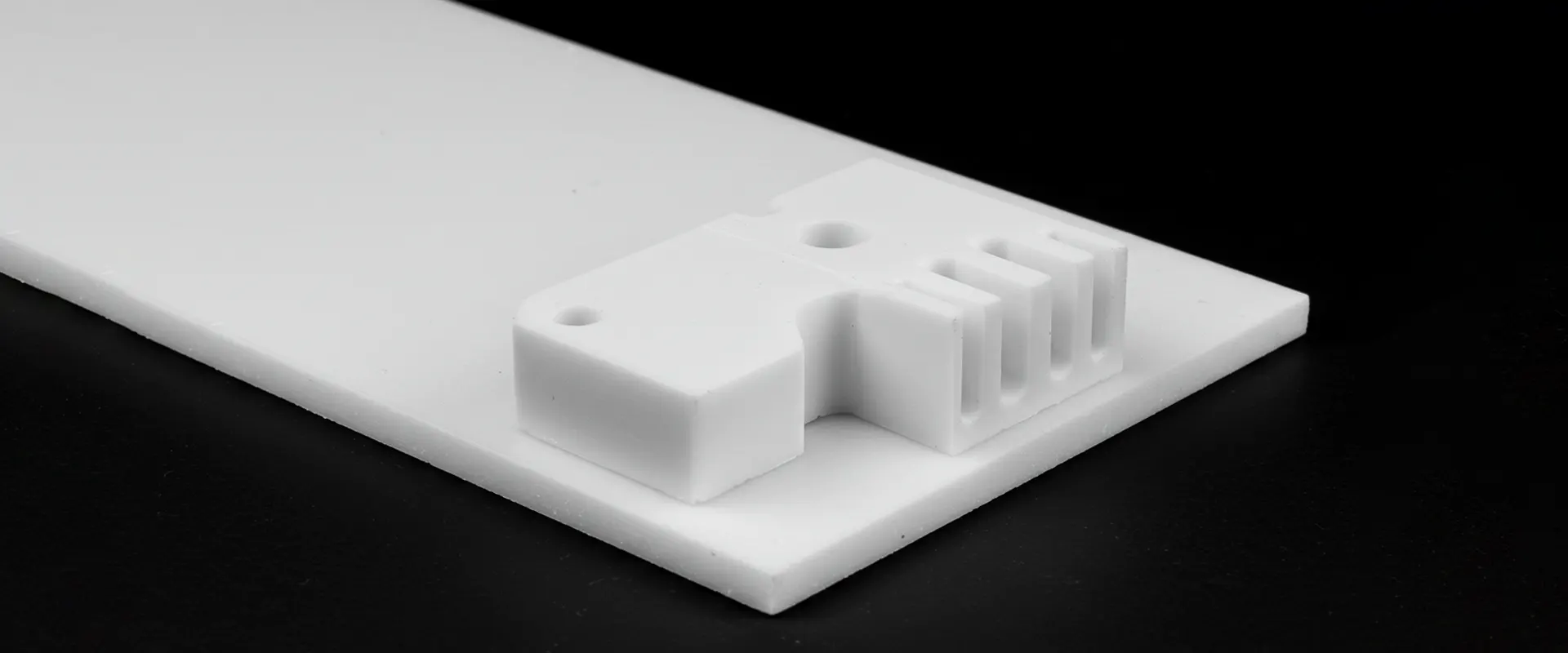

POM

POM, also known as acetal or polyoxymethylene, is a high-strength engineering plastic known for its excellent wear resistance and dimensional stability.

Color:

Black / White

Density

1.4 g/cm³

- PP

PP

PP (Polypropylene) is a lightweight thermoplastic known for its good chemical resistance, flexibility, and low moisture absorption.

Color:

Black

Density:

1.2 g/cm³

- PC

PC

PC (Polycarbonate) is a tough, impact-resistant thermoplastic with excellent transparency and heat resistance.

Color:

Transparent / Black

Density:

1.3 g/cm³

- Nylon (PA6/PA66)

Nylon (PA6/PA66)

Nylon (PA6/PA66) is a strong, durable engineering plastic with good wear resistance and toughness. It is available in thick sizes and suitable for machining.

Color:

Black

Density:

1.3 g/cm³

Available Thickness:

110mm, custom ordered

Lead Time:

1–2 days

Price:

Approx. $5.30/kg

- ABS+PC

ABS+PC

ABS PC material machining is a blend of ABS and polycarbonate, combining toughness, impact resistance, and improved heat resistance. It is widely used in structural components and enclosures.

Color:

Black

Density:

1.3 g/cm³

- PC+ABS

PC+ABS

ABS+PC is a blend of ABS and polycarbonate, combining toughness, impact resistance, and improved heat resistance. It is widely used in structural components and enclosures.

Impact Resistance:

High

Heat Resistance:

Better than pure ABS

- Transparent ABS

Transparent ABS

Transparent ABS is a modified ABS plastic with added clarity, offering a balance of toughness, impact resistance, and transparency. Commonly used for visual parts and casings.

Color:

Transparent

Density:

1.3 g/cm³

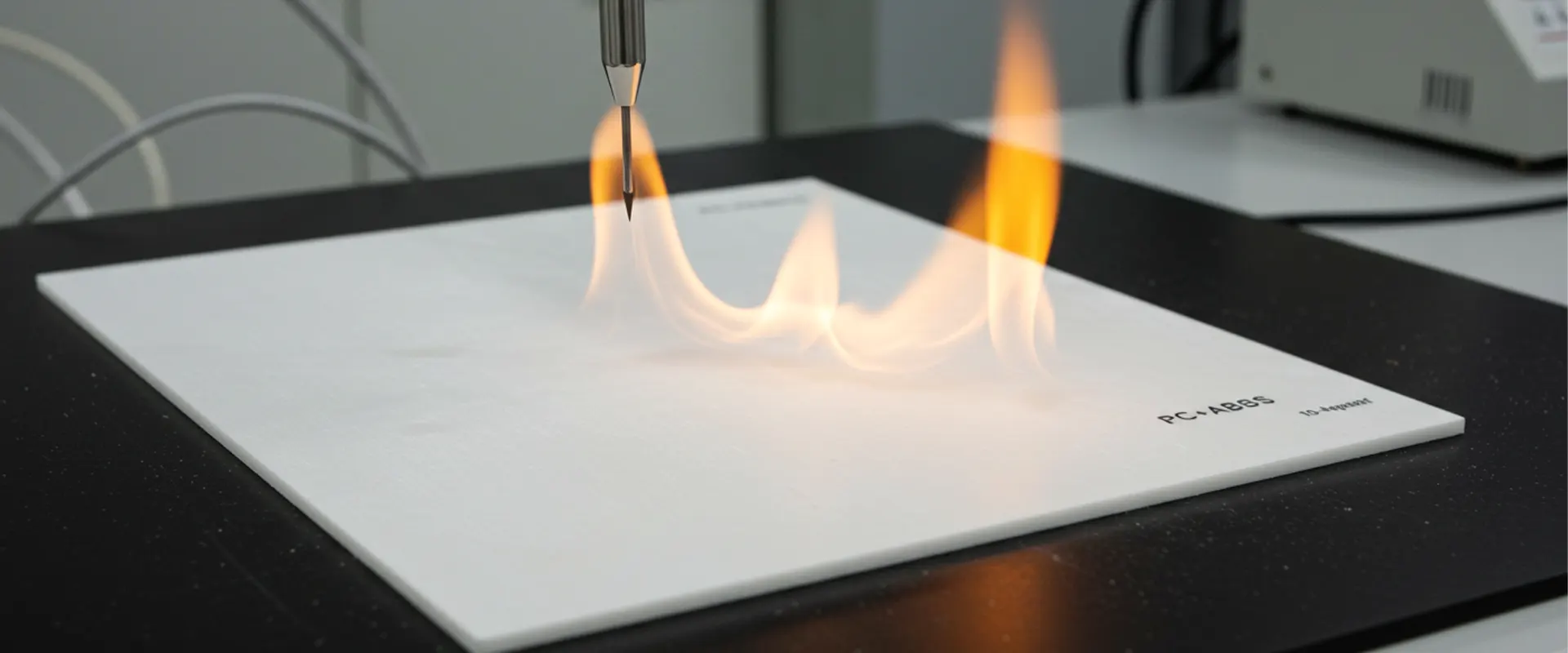

- Flame-Retardant ABS

Flame-Retardant ABS

Flame-retardant ABS is a modified ABS with added fire-resistant properties, commonly used in electronics, appliances, and enclosures requiring safety compliance.

Color:

White

Heat Resistance:

Moderate

- Flame-Retardant PC

Flame-Retardant PC

Flame retardant PC delivers high impact strength, heat resistance, and fire safety—perfect for electronics, automotive, and safety-critical applications.

Impact Resistance:

Excellent

Heat Resistance:

Moderate

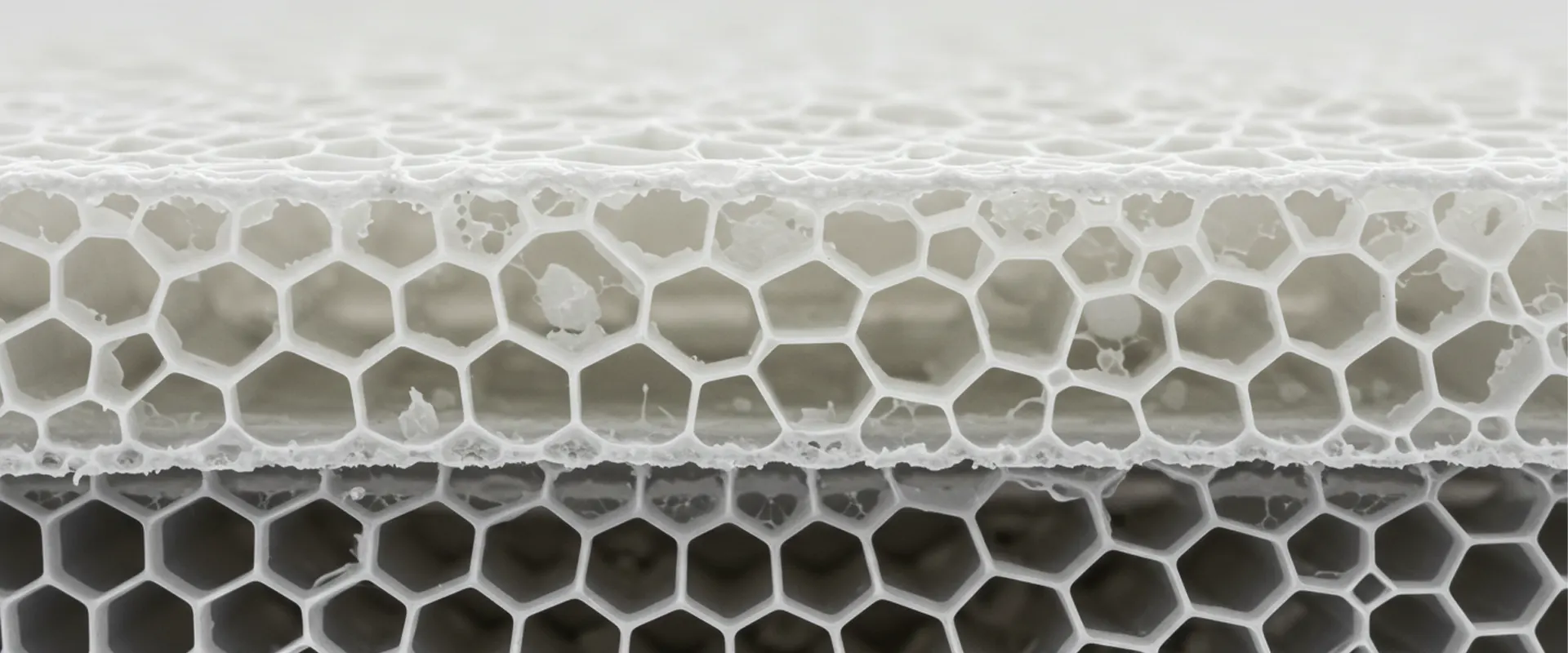

- Glass Fiber Reinforced Nylon (PAFG+30%)

Glass Fiber Reinforced Nylon (PAFG+30%)

PAFG+30% is nylon reinforced with 30% glass fiber, offering significantly enhanced strength, rigidity, and dimensional stability. Ideal for structural parts under mechanical stress.

Color:

Black / Blue

Tensile Strength:

Very high

- PC+GF30%

PC+GF30%

PC+GF30% is polycarbonate reinforced with 30% glass fiber, significantly improving stiffness, dimensional stability, and heat resistance, suitable for structural and load-bearing parts.

Color:

Black

Density:

1.4 g/cm³

- PP+30%

PP+30%

PP+30% is polypropylene reinforced with 30% glass fiber, offering improved stiffness, dimensional stability, and moderate heat resistance. Commonly used in automotive and appliance parts.

Color:

Black

Stiffness:

Enhanced rigidity

- PTFE

PTFE

PTFE, commonly known as Teflon, is a high-performance fluoropolymer with excellent chemical resistance, low friction, and high temperature stability. Widely used in chemical, electrical, and sealing applications.

Density:

2.3 g/cm³

Chemical Resistance:

Excellent

- PEEK

PEEK

PEEK is a high-performance thermoplastic with exceptional strength, chemical resistance, and heat resistance. It is ideal for demanding applications in aerospace, medical, and electronics.

Density:

1.4 g/cm³

Chemical Resistance:

Excellent

- PPS

PPS

PPS is a high-performance engineering thermoplastic with excellent chemical resistance, high-temperature stability, and inherent flame retardancy. It is widely used in automotive, electronics, and chemical applications.

Color:

Black / White

Density:

1.4 g/cm³

- PPE

PPE

PPE is a lightweight engineering plastic with good dimensional stability, electrical insulation, and heat resistance. Often used in electrical components and structural parts.

Color:

Black

Density:

1.2 g/cm³

- PPS+GF40%

PPS+GF40%

PPS+GF40% is polyphenylene sulfide reinforced with 40% glass fiber, offering superior mechanical strength, heat resistance, and dimensional stability. It is ideal for demanding automotive and electrical applications.

Density:

1.7 g/cm³

Mechanical Strength:

Very high

- PES

PES

PES is a high-performance thermoplastic with excellent thermal stability, chemical resistance, and dimensional stability. It is commonly used in medical devices and electronics.

Color:

Black / Brown

Density:

1.3 g/cm³

- Epoxy Resin Sheet

Epoxy Resin Sheet

Epoxy resin sheets are strong, insulating, and durable thermosetting materials ideal for electronics, tooling, and industrial applications.

Density:

2.1 g/cm³

Electrical Insulation:

Excellent

- DSM351

DSM351

DSM351 is a thermosetting engineering material with excellent insulation, high strength, and stability, ideal for electrical and structural applications.

Color:

Brown only

Density:

1.25 g/cm³

- Synthetic Wood

Synthetic Wood

Synthetic wood, also known as imitation wood or Bakelite board (in some contexts), is a high-strength, wear-resistant material used to replace natural wood in industrial applications such as molds, fixtures, and tooling.

Color:

Pink

Wear Resistance:

Good durability under load

- Bakelite

Bakelite

Bakelite, also known as phenolic resin board, is a thermosetting plastic made from phenolic resin and reinforced with paper or fabric layers. It offers excellent electrical insulation, mechanical strength, and heat resistance.

Density:

1.5 g/cm³

Electrical Insulation:

Excellent

- Brown PMMA

Brown PMMA

Brown PMMA is a durable, UV-resistant acrylic with excellent clarity and impact strength—ideal for displays, automotive lighting, and architectural applications.

Density:

1.3 g/cm³

Weather Resistance:

Excellent

- MC Nylon (White)

MC Nylon (White)

MC Nylon (Monomer Casting Nylon) is a type of cast nylon known for its high strength, good wear resistance, and self-lubricating properties. It is suitable for gears, rollers, and structural components.

Color:

White

Mechanical Strength:

High

- PVC

PVC

PVC is a widely used thermoplastic with good chemical resistance, flame retardancy, and electrical insulation. It is available in both rigid and flexible forms and is commonly used in pipes, panels, and insulation covers.

Density:

1.5 g/cm³

Chemical Resistance:

Excellent

- PE

PE

PE is a lightweight, flexible thermoplastic known for its excellent chemical resistance, electrical insulation, and impact strength. It is commonly used in containers, linings, and insulating parts.

Color:

White / Black

Density:

1.0 g/cm³

- Delrin (Acetal) Black

Delrin (Acetal) Black

Delrin, also known as acetal or POM (Polyoxymethylene), is a strong, rigid engineering plastic with excellent wear resistance, dimensional stability, and low friction. Ideal for gears, bushings, and precision mechanical parts.

Color:

Black

Density:

1.45 g/cm³

- Flame-Retardant ABS

Flame-Retardant ABS

Flame-retardant ABS is a modified ABS with added fire-resistant properties, commonly used in electronics, appliances, and enclosures requiring safety compliance.

Color:

White

Heat Resistance:

Moderate

- Rigid PVC

Rigid PVC

Rigid PVC is a hard, durable thermoplastic with excellent chemical resistance, flame retardancy, and good dimensional stability. It is widely used in construction, electrical insulation, and chemical equipment.

Color:

Gray / White

Density:

1.5 g/cm³

- Anti-Static ABS

Anti-Static ABS

Anti-static ABS is a modified ABS material with conductive additives that reduce surface resistivity, preventing static buildup while maintaining the mechanical properties of standard ABS. Ideal for electronic component housings and ESD-safe tooling.

Color:

Black

Density:

1.3 g/cm³

- HDPE

HDPE

HDPE is a strong, lightweight thermoplastic with excellent chemical resistance, impact strength, and water resistance. It is commonly used in piping, containers, cutting boards, and industrial liners.

Color:

White / Black

Density:

1.0 g/cm³

- PA+GF45%

PA+GF45%

PA+GF45% is nylon reinforced with 45% glass fiber, offering extremely high mechanical strength, stiffness, and dimensional stability. It is ideal for structural, load-bearing, and high-temperature applications.

Mechanical Strength:

Extremely high

Dimensional Stability:

Excellent, minimal deformation

- HIPS

HIPS

HIPS is a lightweight, rigid thermoplastic with good impact resistance and ease of fabrication. It is commonly used in vacuum-formed packaging, displays, and internal structural components.

Color:

White / Transparent (10mm+)

Density:

1.2 g/cm³

- Flame-Retardant PC+ABS

Flame-Retardant PC+ABS

Flame-retardant PC+ABS is a blend of polycarbonate and acrylonitrile butadiene styrene modified with flame retardants, combining excellent impact resistance, heat resistance, and flame retardancy. It is widely used in electronics housings and automotive interior parts.

Color:

White

Density:

2.1 g/cm³

- PVC

PVC

PVC is a widely used thermoplastic with good chemical resistance, flame retardancy, and electrical insulation. It is available in both rigid and flexible forms and is commonly used in pipes, panels, and insulation covers.

Density:

1.5 g/cm³

Chemical Resistance:

Excellent

- MC703

MC703

MC703 is a type of monomer casting nylon with enhanced mechanical properties, good wear resistance, and excellent dimensional stability. Commonly used for precision parts and mechanical components.

Color:

Black

Density:

1.2 g/cm³

- POM (NW-02)

POM (NW-02)

POM (Polyoxymethylene) NW-02 is a high-performance engineering plastic available in black and white, known for its excellent stiffness, low friction, and good wear resistance. Ideal for precision mechanical parts.

Color:

Black / White

Density:

1.3 g/cm³

- Conductive POM

Conductive POM

Conductive POM is a modified polyoxymethylene material with added conductive fillers to reduce surface resistivity, providing static dissipation while maintaining mechanical strength and wear resistance. Commonly used in ESD-safe components.

Color:

Black

- PTFE

PTFE

PTFE, commonly known as Teflon, is a high-performance fluoropolymer with excellent chemical resistance, low friction, and high temperature stability. Widely used in chemical, electrical, and sealing applications.

Density:

2.3 g/cm³

Chemical Resistance:

Excellent

- Transparent Anti-static PVC

Transparent Anti-static PVC

Transparent anti-static PVC is a clear thermoplastic modified with anti-static additives to prevent static charge buildup. It combines excellent transparency with static dissipation, commonly used in packaging and protective covers for electronic devices.

Color:

Transparent

- PET

PET

PET is a strong, semi-crystalline thermoplastic known for its excellent mechanical properties, chemical resistance, and dimensional stability. It is widely used in fibers, packaging, and engineering components.

Color:

White

Density:

1.4 g/cm³

- UPE

UPE

UPE is a thermoplastic known for its extremely high impact strength, excellent abrasion resistance, and low friction. It is commonly used in wear parts, liners, and bearings.

Color:

Black / White

Density:

1.0 g/cm³

- PVDF F2

PVDF F2

PVDF F2 is a high-purity fluoropolymer known for excellent chemical resistance, high thermal stability, and good mechanical properties. It is widely used in chemical processing, electrical insulation, and coatings.

Density:

1.8 g/cm³

- Synthetic Wood

Synthetic Wood

Synthetic wood, also known as imitation wood or Bakelite board (in some contexts), is a high-strength, wear-resistant material used to replace natural wood in industrial applications such as molds, fixtures, and tooling.

Color:

Pink

Wear Resistance:

Good durability under load

- White PVC

White PVC

White PVC is a rigid thermoplastic featuring excellent chemical resistance, flame retardancy, and electrical insulation. Commonly used in construction panels, cable insulation, and chemical containers.

Density:

1.5 g/cm³

- Transparent PVC

Transparent PVC

Transparent PVC is a clear, rigid or semi-rigid thermoplastic with good chemical resistance, flame retardancy, and high transparency. It is commonly used in protective covers, display windows, and medical packaging.

Color:

Transparent

Density:

1.5 g/cm³

- FR4

FR4

FR4 is a flame-retardant, glass-reinforced epoxy laminate with excellent electrical insulation, mechanical strength, and moisture resistance. It is widely used in printed circuit boards and insulating structural components.

Color:

Green

Density:

2.1 g/cm³

- Epoxy Resin

Epoxy Resin

Epoxy resin is a high-strength thermosetting polymer with excellent adhesion, chemical resistance, and durability—ideal for coatings, adhesives, composites, and electrical applications.

Color:

Green

Density:

2.1 g/cm³

- Food-Grade PC

Food-Grade PC

Food Grade PC is a tough, transparent, and FDA-compliant plastic ideal for safe food and beverage applications.

Density:

1.2 g/cm³

- POM-Delrin

POM-Delrin

Delrin is a premium grade of POM (Polyoxymethylene), known for its exceptional stiffness, low friction, and excellent dimensional stability. The black variant offers UV resistance and is widely used in precision gears, bearings, bushings, and structural components.

Color:

Black

- PA66+GF15%

PA66+GF15%

PA66+GF15% is nylon 66 reinforced with 15% glass fiber, offering improved stiffness, dimensional stability, and heat resistance compared to unfilled PA66. It is commonly used in automotive parts, electrical housings, and structural components.

Dimensional Stability:

Better than unfilled PA66

- Black PEI

Black PEI

Black PEI is a flame-retardant, heat-resistant thermoplastic with excellent strength and electrical insulation, ideal for aerospace, automotive, and electronics.

Color:

Black

Density:

1.3 g/cm³

Price:

approx. $38.9/kg

- White HDPE

White HDPE

White HDPE is a strong, lightweight thermoplastic with excellent chemical resistance, impact strength, and water resistance. It is commonly used in piping, containers, cutting boards, and industrial liners.

Color:

White

Density:

1.3 g/cm³

- UHMWPE

UHMWPE

UHMWPE is a type of polyethylene with extremely long chains, giving it exceptional impact strength, abrasion resistance, and low friction. It is widely used in medical implants, industrial liners, and wear-resistant components.

Density:

1.3 g/cm³

- Black Copolymer Acetal

Black Copolymer Acetal

The black copolymer acetal you asked about is a type of POM (Polyoxymethylene) copolymer, produced by DuPont. It shares similar properties with standard POM but with enhanced chemical resistance and toughness. Widely used for precision mechanical parts and engineering applications.

Color:

Black

- Ultem 1000

Ultem 1000

Ultem 1000 is a high-performance polyetherimide (PEI) resin known for excellent heat resistance, high strength, and flame retardancy. It is widely used in aerospace, electronics, and medical applications requiring sterilization.

Color:

Amber, Black

Density:

1.3 g/cm³

- PVDF

PVDF

PVDF is a high-purity fluoropolymer with excellent chemical resistance, good mechanical strength, and high thermal stability. The white color resembles candle wax. It is widely used in chemical processing, electrical insulation, and coatings.

Color:

White (similar to candle wax)

Density:

1.8 g/cm³

- Antistatic PEEK

Antistatic PEEK

Antistatic PEEK is an ESD-safe, high-performance thermoplastic with excellent strength, heat resistance, and chemical durability, widely used in aerospace, electronics, and medical applications.

Price:

approx. $135/kg

- Aluminum 6061

Aluminum 6061

Aluminum 6061 is a lightweight, versatile alloy with excellent strength, corrosion resistance, and weldability. Widely used in aerospace, automotive, marine, and structural engineering.

Density:

2.8 g/cm³

- Aluminum A5052

Aluminum A5052

Aluminum A5052 is a strong, corrosion-resistant alloy with excellent weldability, ideal for marine, automotive, and industrial applications.

Density:

2.8 g/cm³

Price:

approx. $ 2.98/kg

- ADC12

ADC12

ADC12 is a widely used die-casting aluminum alloy known for good casting performance, high strength, and excellent corrosion resistance. It is commonly used in automotive parts, electronics housings, and machinery components.

Alloy:

ADC12

Casting Performance:

Excellent for die casting

- LY12

LY12

LY12 is a high-strength, heat-treatable aluminum alloy primarily composed of aluminum and copper. It offers excellent fatigue resistance and good machinability, but lower corrosion resistance. Widely used in aerospace, transportation, and structural components.

Density:

2.8 g/cm³

Fatigue Resistance:

Excellent

- AL T6

AL T6

AL T6 is a heat-treated aluminum alloy with excellent strength, corrosion resistance, and good machinability. The “T6” temper indicates it has been solution heat-treated and artificially aged to achieve peak mechanical properties. Widely used in aerospace, automotive, and structural parts.

Alloy:

AL T6

Casting Performance:

Excellent for die casting

- AL T51

AL T51

T51 is a temper designation applied to aluminum alloys that have been stress-relieved by stretching after heat treatment. Commonly seen in alloys like 6061-T51 and 7075-T51, this temper improves dimensional stability and reduces internal stress, while maintaining good strength and corrosion resistance.

Alloy:

AL T51

Casting Performance:

Excellent for die casting

- A1100

A1100

A1100 is commercially pure aluminum (99%+ purity) with excellent corrosion resistance, workability, and thermal conductivity. It is soft, ductile, and non-heat-treatable. Widely used in chemical equipment, roofing, cooking utensils, and decorative parts.

- Aluminum Alloy 2A12

Aluminum Alloy 2A12

2A12 is a high-strength aluminum-copper alloy commonly used in aerospace and high-load structural applications. It offers excellent fatigue resistance and good machining performance but has relatively low corrosion resistance, so surface treatment is often required.

- 2A12

2A12

2A12 is a high-strength, heat-treatable aluminum-copper alloy, widely used in aerospace, transportation, and structural components. It is known for its excellent fatigue resistance and good machinability. However, its corrosion resistance is lower compared to non-copper alloys, so surface protection is usually required.

- Alumina Ceramic

Alumina Ceramic

Alumina ceramic with >90% Al₂O₃ content is a high-hardness, high-temperature ceramic material used for wear resistance, electrical insulation, and cutting tools.

- Brass

Brass

Brass is a copper-zinc alloy known for its good mechanical properties, excellent corrosion resistance, and attractive golden color. It is widely used in decorative fittings, electrical components, plumbing, and precision machined parts.

Density:

8.9 g/cm³

- Copper (CU)

Copper (CU)

Copper is a versatile metal with excellent conductivity, corrosion resistance, and durability, widely used in electrical, industrial, and structural applications.

Color:

Brass/Bronze/Copper

Density:

8.9 g/cm³

- Magnesium Alloy

Magnesium Alloy

Magnesium alloy is a lightweight metal alloy known for its high strength-to-weight ratio, excellent machinability, and good vibration damping. It is widely used in aerospace, automotive, and electronics industries where weight reduction is critical.

Density:

1.9 g/cm³

- Zinc Alloy (Zn)

Zinc Alloy (Zn)

Zinc alloy is a versatile metal alloy known for its good strength, excellent castability, and corrosion resistance. It is widely used in die casting for automotive parts, hardware fittings, and decorative items.

Density:

6.8 g/cm³

- Aluminum 3003

Aluminum 3003

Aluminum 3003 is a commercially pure aluminum alloy with manganese as the primary alloying element. It offers good corrosion resistance, excellent workability, and moderate strength. It is commonly used in roofing, siding, and cookware applications.

- Aluminum A5056

Aluminum A5056

Aluminum A5056 is a strong, corrosion-resistant alloy with excellent weldability, widely used in marine, automotive, and industrial applications.

Density:

2.8 g/cm³

- A2017

A2017

A2017 is a high-strength aluminum-copper alloy known for excellent machinability and good mechanical properties. It is commonly used in aerospace, transportation, and precision machinery. Corrosion resistance is moderate, often requiring surface treatment.

Density:

2.8 g/cm³

- Copper Alloy C3604

Copper Alloy C3604

Copper Alloy C3604 is a free-cutting brass with excellent machinability, corrosion resistance, and strength, ideal for precision parts and fittings.

Density:

8.9 g/cm³

- Aluminum Alloy 5000

Aluminum Alloy 5000

The 5000 series aluminum alloys are magnesium-based alloys known for excellent corrosion resistance, good weldability, and moderate to high strength. They are widely used in marine, automotive, and structural applications.

- AL1070

AL1070

AL1070 is a commercially pure aluminum with very high electrical and thermal conductivity, excellent corrosion resistance, and good workability. It is commonly used in electrical conductors, heat exchangers, and chemical equipment.

- Aluminum Alloy AL2024 / A2024-T6

Aluminum Alloy AL2024 / A2024-T6

AL2024 is a high-strength aluminum-copper alloy widely used in aerospace and structural applications. The T6 temper means it is solution heat-treated and artificially aged to achieve high mechanical strength. It offers excellent fatigue resistance but moderate corrosion resistance, so surface protection is usually necessary.

- Aluminum Alloys AL7075 / 7050 / 7451

Aluminum Alloys AL7075 / 7050 / 7451

Aluminum Alloys 7075, 7050, and 7451 are high-strength zinc-based materials with excellent fatigue resistance, widely used in aerospace, defense, and high-performance structural applications.

Density:

2.8 g/cm³

- Imported Aluminum Alloy 5083

Imported Aluminum Alloy 5083

Aluminum Alloy 5083 is a high-strength, corrosion-resistant alloy ideal for marine, automotive, cryogenic, and structural applications.

- Imported Aluminum Alloy 6082

Imported Aluminum Alloy 6082

Aluminum Alloy 6082 is a medium-strength heat-treatable aluminum-magnesium-silicon alloy, widely used in structural and engineering applications. It offers good corrosion resistance, excellent weldability, and good machinability. Imported 6082 generally meets strict international standards for quality and performance.

- Imported Aluminum Alloy 7075

Imported Aluminum Alloy 7075

Imported Aluminum Alloy 7075 is a high-strength, aerospace-grade material with excellent fatigue resistance and toughness, widely used in aerospace, defense, and performance engineering.

- Imported Aluminum Alloy 6061-T561

Imported Aluminum Alloy 6061-T561

6061-T561 is a heat-treated aluminum-magnesium-silicon alloy known for good mechanical strength, excellent corrosion resistance, and very good machinability. The T561 temper indicates it has been solution heat-treated, stress relieved by stretching, and artificially aged. It is widely used in structural parts, automotive, and precision components. Imported material meets strict international standards for quality and consistency.

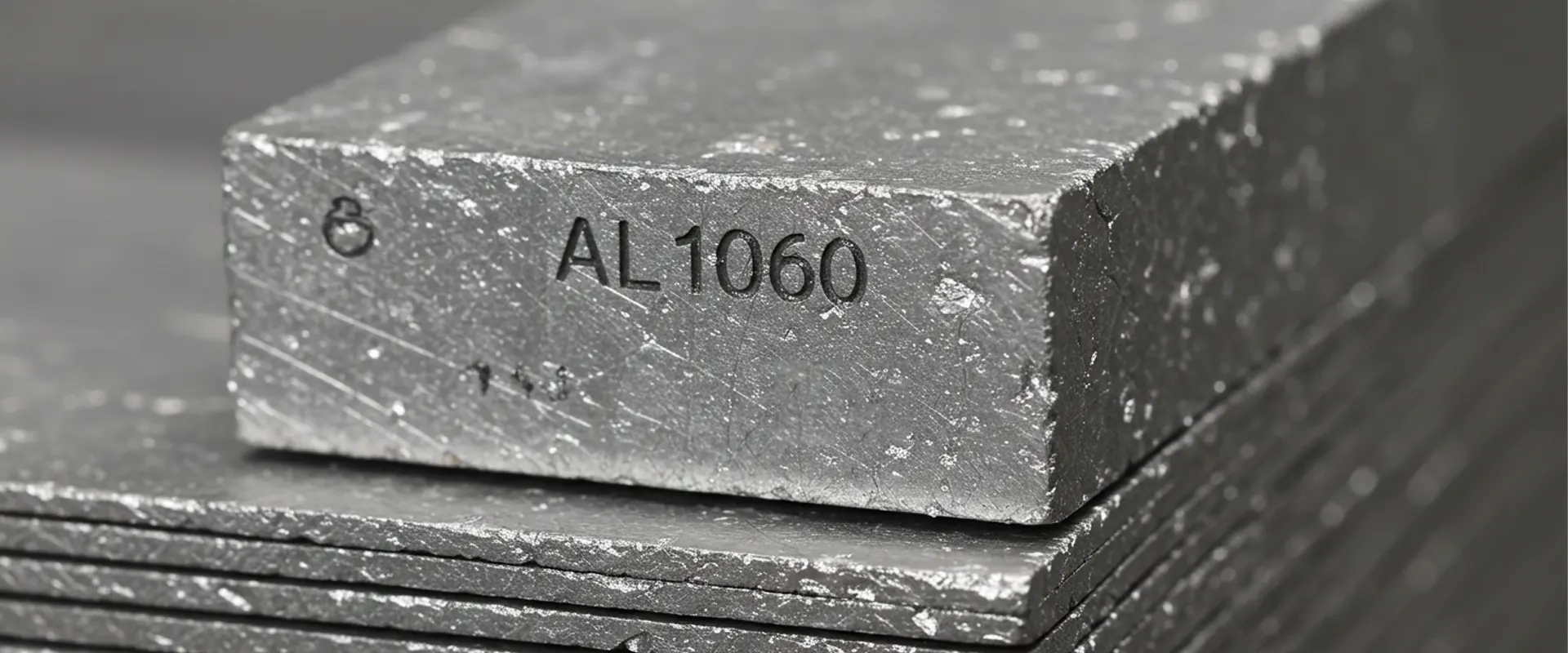

- AL1060

AL1060

AL1060 is a commercially pure aluminum alloy with an aluminum content of about 99.6%. It has excellent electrical and thermal conductivity, outstanding corrosion resistance, and very good formability. Commonly used in electrical conductors, chemical equipment, and sheet metal parts.

- 2A14

2A14

2A14 is a high-strength aluminum-copper alloy with good heat treatability and excellent mechanical properties. It offers good machinability and moderate corrosion resistance, making it suitable for aerospace structural parts, high-load components, and precision engineering.

Density

8.0

- C2801P-1/2H

C2801P-1/2H

C2801P is a brass alloy with around 60% copper and 40% zinc, known as "Muntz metal" or alpha-beta brass. The “1/2H” indicates half-hard temper, giving it moderate strength with better formability compared to full hard. It offers good corrosion resistance, good cold workability, and is commonly used for architectural trim, hardware, and decorative parts.

- C1020P machining

C1020P machining

C1020P is a high-purity oxygen-free copper (OFC) with excellent electrical and thermal conductivity, outstanding ductility, and good corrosion resistance. It is widely used in electrical applications, electronic components, and vacuum devices where high conductivity and cleanliness are critical.

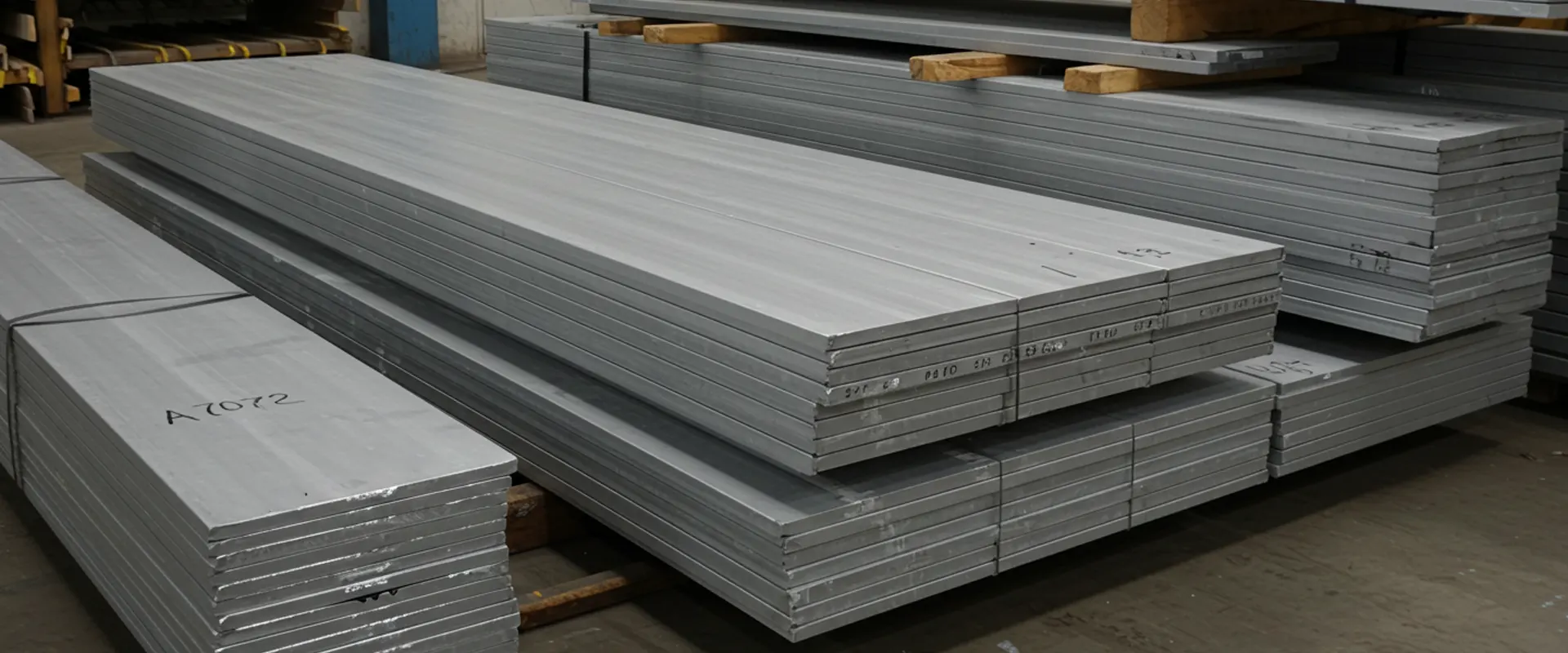

- A7072

A7072

A7072 is an aluminum alloy mainly alloyed with zinc (around 1%) and designed primarily for cladding on heat exchanger tubes and other applications that require good corrosion resistance. It has excellent corrosion resistance, good formability, and is often used as a cladding layer on high-strength core alloys (like 3003 or 7075) to enhance corrosion protection.

Density:

2.8

- A7000

A7000

The A7000 series refers to high-strength aluminum-zinc-magnesium-copper alloys. Known for excellent mechanical strength and good fatigue resistance, they are widely used in aerospace, military, and high-performance engineering applications. Typical grades include 7005, 7050, 7075, and 7049. While strength is very high, corrosion resistance is moderate, so surface treatments are usually applied.

Density:

2.8

- C1100

C1100

C1100 is a commercially pure copper (also known as electrolytic tough pitch copper, ETP) with very high electrical and thermal conductivity, excellent ductility, and good corrosion resistance. It is widely used in electrical conductors, bus bars, wiring, and heat exchangers.

Density:

8.9

- A2014

A2014

A2014 is a high-strength aluminum-copper alloy known for excellent machinability, good mechanical properties, and fair corrosion resistance. It is often used in aerospace parts, heavy-duty forgings, and precision components requiring high strength and good wear resistance.

Density:

2.8 g/cm³

- Titanium Alloy

Titanium Alloy

Titanium alloys are known for their high strength-to-weight ratio, excellent corrosion resistance, and good biocompatibility. They are widely used in aerospace, medical implants, chemical processing, and high-performance engineering applications. Despite being lightweight (density about 4.6 g/cm³), titanium alloys offer superior mechanical properties and resistance to extreme environments.

Density:

4.6

- 7075

7075

7075 is a high-strength aluminum-zinc-magnesium-copper alloy, widely used in aerospace, military, and high-performance engineering parts. It features excellent mechanical strength and fatigue resistance, with moderate corrosion resistance—so it’s often treated with anodizing or coatings.

- A2011

A2011

A2011 is a free-machining aluminum-copper alloy known for excellent machinability and good mechanical strength. It is often used for high-speed automatic lathes, precision turned parts, and screw machine products. It offers fair corrosion resistance and is typically used where complex shapes and fast production are required.

Density:

2.8 g/cm³

- A2024

A2024

A2024 is a high-strength aluminum-copper alloy, widely recognized for its excellent fatigue resistance and good machinability. It is commonly used in aerospace structures, rivets, and precision components requiring high strength-to-weight ratio. While it has good mechanical properties, its corrosion resistance is moderate and often needs protective coatings.

Density:

2.8 g/cm³

- A7050

A7050

A7050 is a high-strength aluminum-zinc-magnesium-copper alloy designed mainly for aerospace structural applications. It offers very high strength, excellent fracture toughness, and good stress corrosion cracking resistance—making it suitable for thick sections and critical parts. Its overall corrosion resistance is better than some other 7000 series alloys like 7075.

Density:

2.8 g/cm³

- 11SMn30

11SMn30

11SMn30 is a free-cutting non-alloy steel with added sulfur (~0.27–0.33%) to improve machinability. It offers very good machinability, making it ideal for high-volume production of turned parts, screws, and fittings. However, due to higher sulfur content, its weldability and toughness are limited.

Density:

7.9 g/cm³

If you do not see the material stock you are looking for, please choose "Custom" under the material drop-down on your quote page and submit for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required. contact us

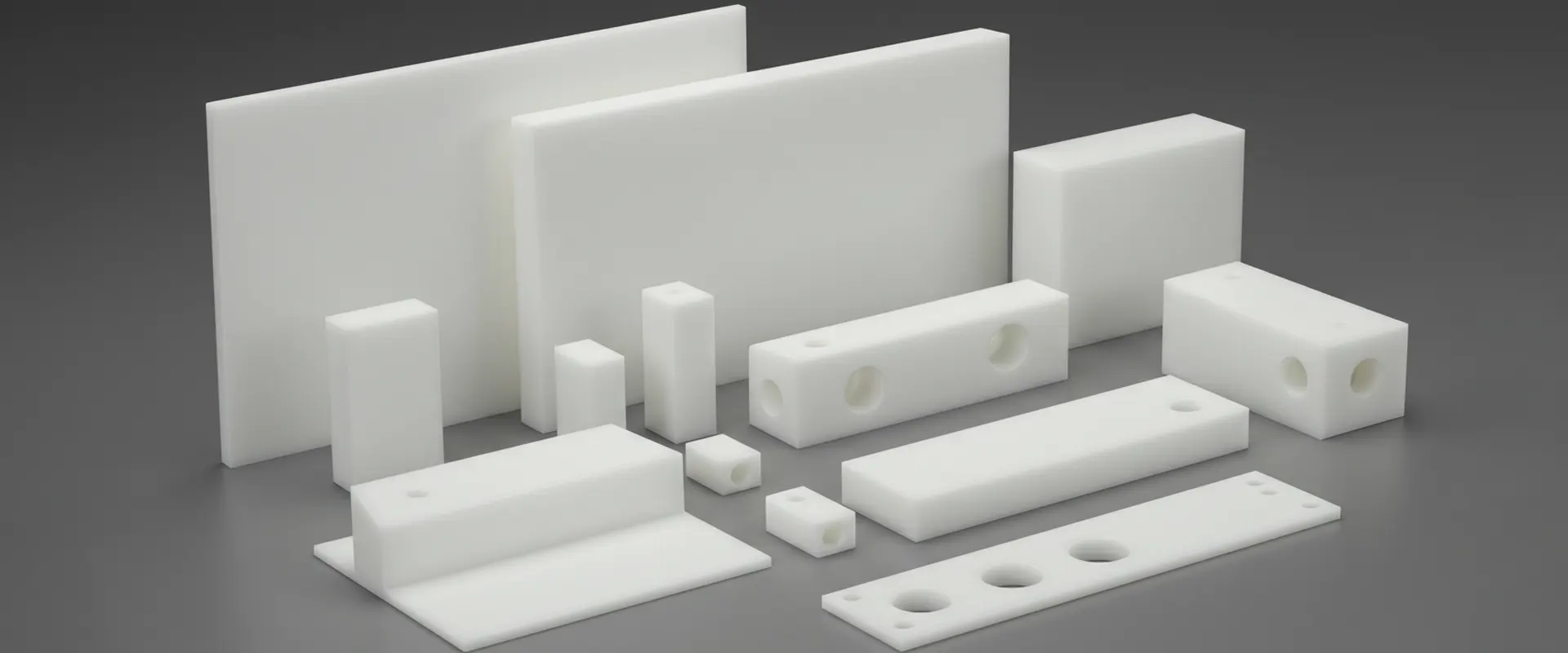

Small Molded Parts within Days

Our complete CNC aluminum service will accompany your aluminum machining project from the prototype construction to the end aluminum parts manufacturing.

Finishing Options for 3D Printing

Enhance your 3D printed parts with professional finishing:

-

Standard Finish – Cleaned and basic smoothness.

-

Painting – Color, gloss, and texture customization.

-

Polishing – High surface smoothness and shine.

-

Electroplating – Thin metal layer for appearance & conductivity.

-

Dyeing – Even color finish for nylon parts.

-

Vapor Smoothing – Glossy, smoothed ABS and ASA parts.

-

Clear Coating – Transparent protective layer for clarity.

-

Bead Blasting – Matte, uniform finish.

-

Heat Treatment – Strengthens metal parts.

| Name | Description | Services | Applicable Materials | |

|

Standard Finish | Parts cleaned and support structures removed for basic smoothness. | CNC milling & turning | Metals, plastics |

|

Painting | Surface coated to achieve color, gloss, and texture. | Spray painting, hand painting | Plastics, resins |

|

Polishing | Enhances surface smoothness and shine for better appearance. | Mechanical polishing, manual buffing | Plastics, resins |

|

Electroplating | Applies thin metal layer for improved appearance and conductivity. | Copper, nickel, chrome plating | Suitable resin parts |

|

Dyeing | Immerses parts in dye for uniform color. | Immersion dyeing | Nylon (SLS/MJF parts) |

|

Vapor Smoothing | Uses solvent vapor to smooth layer lines and create glossy surfaces. | Chemical vapor treatment | ABS, ASA, some nylons |

|

Clear Coating | Transparent coating to protect and enhance clarity. | Spray clear coat | Transparent SLA resin, PC, PMMA |

|

Bead Blasting | Creates uniform matte finish and removes build marks. | Blasting with fine media | Plastics, metals |

|

Heat Treatment | Improves strength and durability for metal printed parts. | Controlled heating and cooling | Metal parts from DMLS/SLM |

If you do not see the surface finish you are looking for, please choose “Custom” on the quote page. After specifying features, tolerances, inspection requirements, and quantities, submit for an expert engineering review — or simply contact us for support.

One-Stop 3D Printing Parts Supplier

GD Prototyping offers a one-stop 3D printing service combining fast delivery, high-quality standards, and expert manufacturing solutions to meet diverse project needs efficiently.

-

Comprehensive Solutions

At GD Prototyping, we provide endless manufacturing options and expert design guidance to optimize your part geometry.

-

Fast delivery

-

High precision

-

Realistic look & feel

-

-

Fast Reliable Delivery

3D printing lead times start from 48 hours. Every part is inspected and tested with photos and reports before shipment.

-

Flexible scaling

-

Cost-effective

-

Reliable quality

-

-

Manufacturing Expertise

We offer tailored processing solutions based on your part’s geometry and usage, acting as your trusted manufacturing partner.

-

Wide material options

-

Tight tolerances

-

Consistent reliability

-

Join Over 3,000 Companies Using GD for Quality Parts

From prototypes to production-ready parts, GD Prototyping delivers cutting-edge 3D printing solutions tailored to your needs.

An Engineering Show For Product Developers

CNC machining is an ideal manufacturing process whether you need a few parts or 10000+ units as end-used production parts. Here are the custom CNC services available at GD prototyping.

-

Precision 3D Printing

Showcasing GD Prototyping’s SLA and SLS 3D printing services for fast, accurate, and high-quality production of complex plastic and metal parts.

-

Mirror Bowl Machining

Precision five-axis CNC machining forms reflective bowls, followed by electroplating and polishing to achieve smooth, mirror-like surfaces.

-

Impeller Five-Axis

GD Prototyping uses precision five-axis CNC machining to craft complex impellers with smooth surfaces and tight tolerances for high performance.

Frequently Asked Questions

Here are answers to common questions about industrial PCs and automation solutions. Need more details? Contact our experts at sales08@gd-prototype.com

-

What services does GD Prototyping offer?

-

What industries do you serve?

-

What materials can you work with?

-

How fast can I get a quote?

-

What’s your typical lead time?

What Our Customers Say

Customized Process

With years of manufacturing experience, GD Prototyping provides the best solutions for all rapid prototyping and low-volume manufacturing needs. We simplify the innovation cycle into four simple but effective steps.

Flexible Design Iterations

Creating low volume manufacturing allows for more efficient verification of design, engineering and manufacturability.

Short Turnaround Times

Tooling is cost-effective for low volume manufacturers to handle orders quickly and flexibly, with no minimum order quantities.

Close the Production Gap

Low-volume pilot runs bridge the gap between prototype and production, identifying and resolving any issues before entering series production.

Reduced Time to Market

Low-volume manufacturing services optimize the connection between production, supply chain and consumers, providing fast time-to-market for new products.

Get Your Parts Into Production Today

Our complete CNC aluminum service will accompany your aluminum machining project from the prototype construction to the end aluminum parts manufacturing.

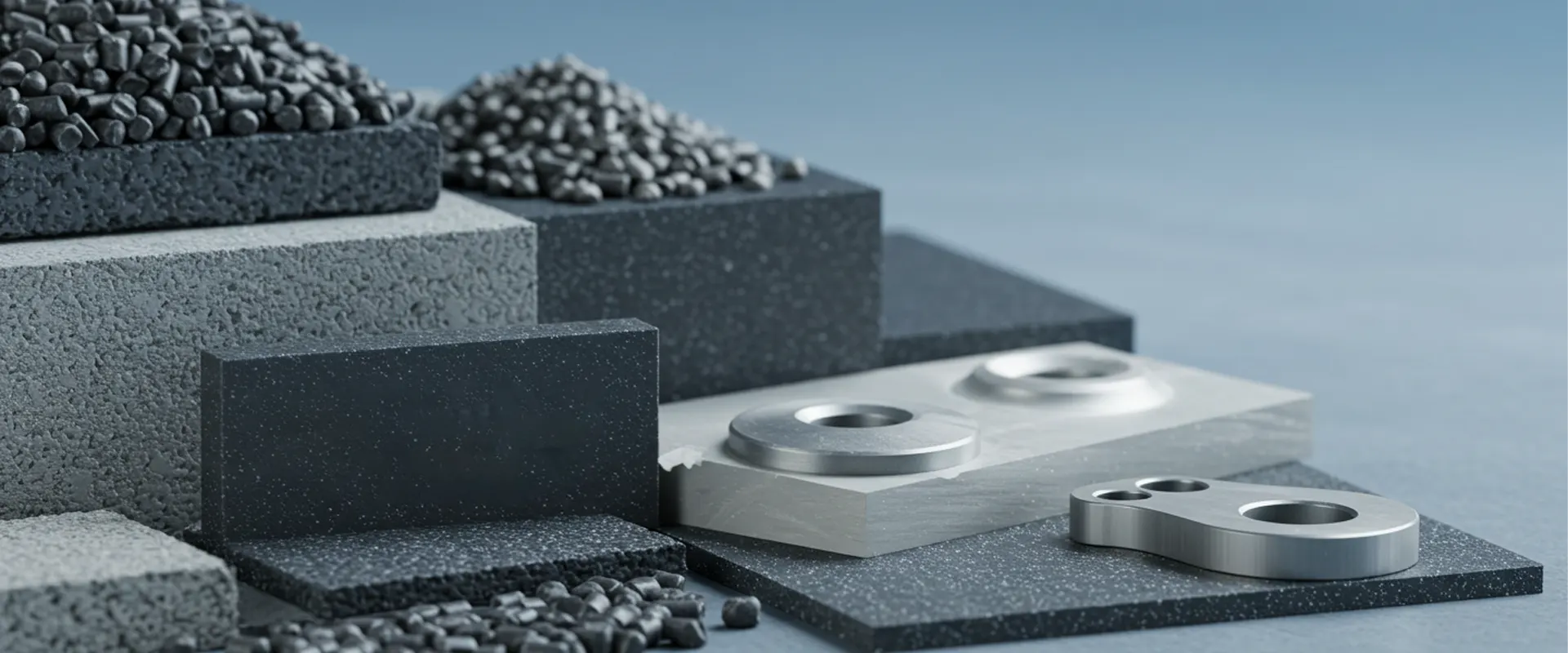

At GD Prototyping, our 3D Printing services provide rapid prototyping and production-ready parts with speed, accuracy, and cost efficiency. Using advanced additive manufacturing technologies—including SLA, SLS, FDM, and DMLS—we transform digital CAD models into physical components with minimal lead time.

3D printing enables the creation of complex geometries that are difficult or impossible to achieve with traditional methods. From functional prototypes to small-batch production runs, it allows businesses to validate designs, test functionality, and accelerate time to market.

We support a wide range of materials, including engineering-grade plastics, resins, composites, and metals such as aluminum, stainless steel, and titanium. This flexibility makes 3D printing suitable for industries ranging from aerospace to consumer goods.

With GD Prototyping, you get more than just parts—you get precision-engineered solutions, consistent quality, and access to cutting-edge additive manufacturing that reduces cost while maintaining performance. Whether you need concept models, functional prototypes, or low-volume production, our 3D Printing services help bring your ideas to life with unmatched speed and detail.

Applications of 3D Printing

- Rapid Prototyping – Quickly produce concept models and functional prototypes.

- Medical Devices – Custom implants, surgical guides, and precision tools.

- Automotive Industry – Lightweight parts, housings, and interior components.

- Aerospace – Complex, lightweight metal and composite structures.

- Consumer Products – Custom gadgets, appliance housings, and product samples.

- Industrial Equipment – Low-volume machine parts and custom tooling.